3D-Hybrid, a machine tool company based in California, has released a set of printheads that deliver metal additive manufacturing to existing CNC machines. According to the company, the range can be installed in “nearly any CNC machine,” turning it into a hybrid additive and subtractive manufacturing system.

WAAM, LMD and Cold Spray

3D-Hybrid’s range of metal 3D printheads are available for Wire-Arc Additive Manufacturing (WAAM), Laser Metal Deposition (LMD), and Cold Spray technologies.

Based on classic welding technology, WAAM uses an alloy wire feedstock, and has been successfully in projects by Cranfield University and Damen Shipyards – that used the technology to make the ship WAAMpeller.

In contrast, LMD and Cold Spray are powder based processes.

LMD is the technology used by company such as TWI and TRUMPF. With a high build up rate of material, LMD is a comparatively high speed metal additive process. It can either be used to add to pre-made surface, or to build a part from scratch. When combined with other processes, LMD is efficient at making different versions of stock product.

Cold Spray, a technology at the base of systems such as SPEE3D’s LightSPEE3D 3D printer, can create metal parts at room temperature. In an aircraft repair project, the University of Akron and Airborne Maintenance & Engineering Services (AMES) are seeking Federal Aviation Administration approval for the process.

Hybrid repair

By combining additive and subtractive technologies, 3D-Hybrid’s tool heads are well-suited to part refurbishment and repair services, saving time, materials, and money in the process.

At the time of writing, each head has a market entry price of $50,000 USD, placing it competitively under the cost of a whole metal additive system. The heads also have the added benefit of installation into an already familiar system, making them a good introduction for companies seeking to expand their manufacturing capabilities.

For all the latest hardware, software, and materials releases subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

3D Printing Industry Jobs is live. Post a job or discover your next career move now.

Protolabs is sponsoring the 2018 3D Printing Industry Awards design competition. Submit your entries now with the chance of winning a 3D printer.

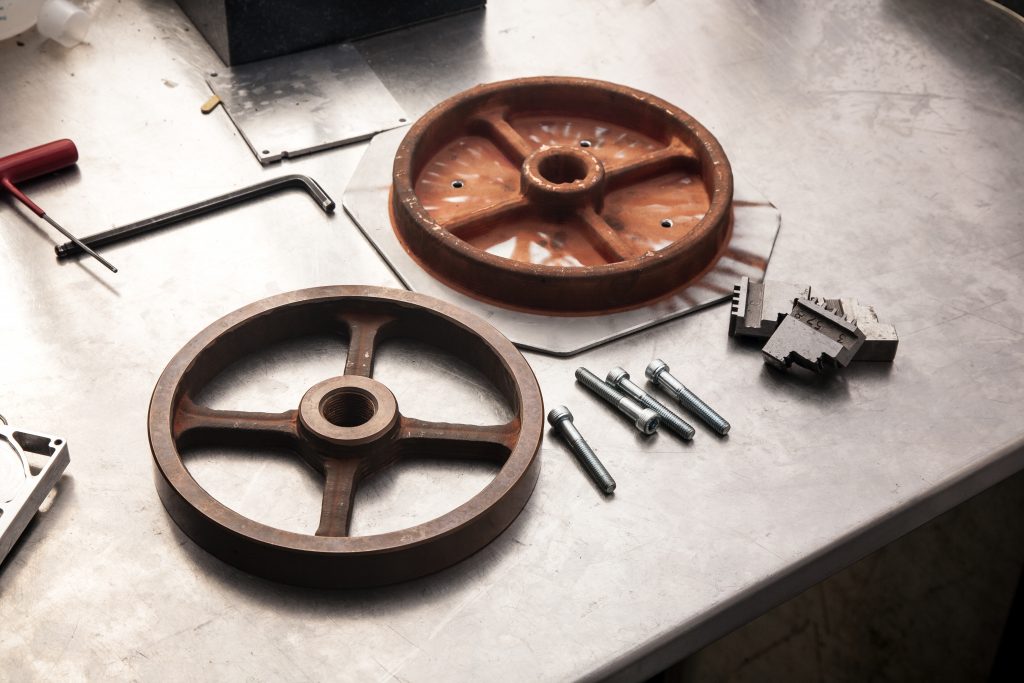

Featured image shows 3D-Hybrid’s CNC installable printheads. Image via 3D-Hybrid