In 2012 when the University of Wisconsin at Madison’s Mechanical Engineering Department was gifted a new Sinterstation 2500 selective laser sintering 3D printer it didn’t take long for the machine to change the dynamics of the campus. The 3D printer quickly started bringing in students and faculty from disparate disciplines and inspiring them to work together. The co-director of the Polymer Engineering Center, Professor Tim Osswald, explained, “The SLS machine is a catalyst for new ideas and opportunities. It’s triggering interdisciplinary collaborations and new thinking among all kinds of people, which is really cool.”

The Sinterstation 2500 is a massive industrial, 3D printer that is bigger than a compact car, but with the price of an Aston Martin. A printer that size is made for mass production of parts with complex geometries and is capable of creating objects that could never be manufactured with any other method. That kind of versatility is ideal for an educational institution, and the students at UW-Madison are taking full advantage of it.

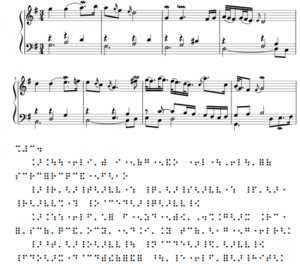

One of the more interesting collaborations was spurred when grad student William Aquite saw a video profile of a blind student from the School of Music. Yeaji Kim, as with all blind musicians, generally plays using musical scores translated into Braille. Unfortunately, Braille is incapable of communicating some of the complexity of sheet music, which has the potential to slow a sight-impaired musician’s education down considerably. So, Kim decided to create her own system that raises the type on the sheet music directly, allowing her to get more information about the piece, without overcomplicating the Braille.

Aquite felt that he could help Kim fabricate the sheet music for her specialized system with even more detail, using the PEC lab’s SLS 3D printer. With Prof. Osswald’s help, Aquite presented the idea to Kim, who eagerly accepted the offer.

“Kim was interested in the idea and definitely excited about collaborating,” said Aquite. “This isn’t just building a prototype for her or the School of Music. It’s a true collaboration in that we’re working closely with Kim to understand her design needs and to find solutions together.”

The new method of producing sheet music could radically change the level of accessibility for music education. With this new 3D printed sheet music, a visually impaired musician would be able to read the same music that a sighted person could read visually. Osswald and Aquite have an entire team of undergraduate and graduate students working on new sheet music.

Kim, who has since finished school and returned to South Korea, closely advises the whole process. When Osswald’s team creates a new 3D printed version of Kim’s music, they send it directly to her to try out. Kim checks the music and then reports back on the surface quality and the music’s dimensional accuracy. After discussing her feedback, the team gets back to work, perfecting the process.

Of course, sheet music for the blind isn’t the only unique collaboration on the UW-Madison campus. A student studying in the School of Human Ecology recently teamed up with a mechanical engineering student for an undergraduate research project to experiment with 3D printed textiles. And, recently, a scientist from the School of Medicine and Public Health sought help from Osswald and his students in developing a process to quickly and easily 3D print a patient’s internal anatomy to aid in pre-surgical planning. Stay tuned, as there will be plenty more stories like this to come from the Polymer Engineering Center.