In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions in the additive manufacturing sector.

Today’s edition features fully-revamped software, a $15 million share offering, on-demand 3D printed electronics, multiple new installations and a commitment from several AM companies, to get more female engineers into the industry.

Read on for the most recent updates from PADT, Titomic, Rosswag, Jellypipe, Freemelt, CoreTechnologie, Gen3D, Electronic Alchemy and more.

Titomic, PADT, ExOne expand seller networks

This week’s round-up starts with the latest distribution deals, and the news that binder jet 3D printer manufacturer ExOne has authorized USC Solutions to sell its machines in Singapore, Malaysia and Indonesia. The move sees ExOne add to its growing list of regional partners, and expand into a market that’s showing increased appetite for its technologies.

“We’re excited to have the experienced team from USC Solutions represent us,” said Ben Leung, VP of ExOne Asia. “We look forward to leveraging their reputation of providing solutions in the local manufacturing market. ExOne continues to grow in Asia, and we expect USC Solutions to play a key role in strengthening our network.”

On a similar note, Australian 3D printer manufacturer Titomic has announced a partnership with the Indian 3D printing service bureau Shree Rapid Technologies. The deal effectively enables Titomic to market its technologies in India, while working towards meeting the strict durability and temperature standards needed, to become a military contractor there.

“Banking on their experience in the market and the successes of Shree Rapid Technologies in India, makes us optimistic that the relationship is another important step in spreading TFK technology across the globe, for the benefit of our customers,” explained Norbert Schulze, Interim CEO of Titomic.

3D printing service provider Phoenix Analysis & Design Technologies (PADT) has been recognized by 3D printer OEM Stratasys as a Diamond Partner. The accolade acknowledges PADT’s role as an elite Stratasys reseller, in addition to its excellent client support and a partnership between the firms that dates back to the 1990s.

“For more than 25 years, PADT has provided the highest level of 3D printing products, services and support to our customers across the Southwest,” said Jim Sanford, VP of Sales & Support at PADT. “Earning the Stratasys Diamond partner designation is a result of the hard work of our team, and the continued respect of our customers.”

Installations at NCAM, Rosswag and Freemelt

The National Centre for Additive Manufacturing (NCAM), based at the Manufacturing Technology Centre (MTC) in the UK, has boosted its polymer 3D printing capabilities by installing a Carbon M2 3D printer. As a ‘Carbon Production Network Partner,’ the MTC has already used similar technologies extensively, and the move essentially expands the portfolio of materials it’s capable of processing.

Leveraging the M2, the MTC is now able to 3D print elastomers, silicones and polyurethanes into high-performance parts, that are resistant to temperatures of up to 230oC. The group’s robust new polymer range also has wide-ranging potential applications, including the production of industrial heat sinks, as well as wearables and automotive components.

“The NCAM has been influential in inspiring British manufacturing,” said Gary Miller, head of European partner and market development at Carbon. “By leveraging the Carbon DLS process and engineering-grade materials, the MTC is well-positioned to highlight the discovery of applications that outperform at every step.”

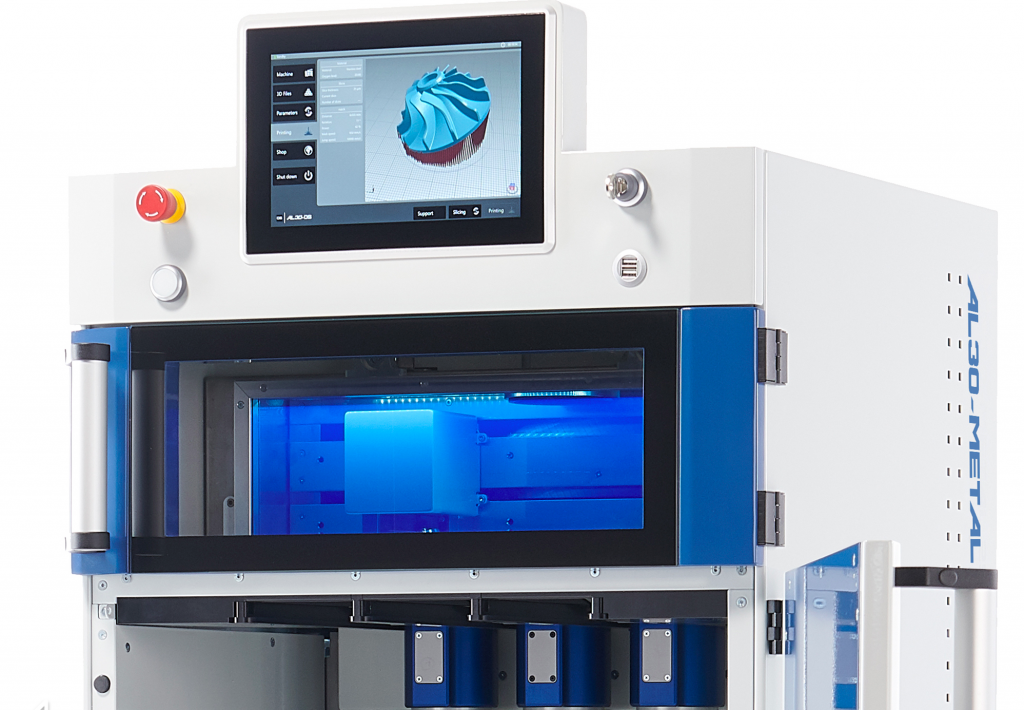

Similarly, metal processing firm Rosswag Engineering has also built on its 3D printing capabilities, by adding Alpha Laser’s AL3D-METAL LPBF system to its holistic processing chain. Rosswag’s qualification setup is based on the in-house testing of small powder quantities, and the compact machine could prove ideal for the task.

Once the company has identified its ideal parameter sets, the 3D printer’s derived transfer function will also allow them to be directly scaled for entering prototype production. This feature, combined with the machine’s three-cartridge configuration, should provide Rosswag with a more rapid qualification workflow that allows for ultra-convenient powder handling.

Sweden-based metal 3D printing company Freemelt has revealed that it recently received an order from its native KTH Royal Institute of Technology for two new machines. Both systems are set to be delivered in 2021, with one to be utilized within advanced materials research, and the other shipped to Germany as part of a collaborative radiation project.

“These orders confirm our position as a prime supplier of 3D printers for cutting-edge material research,” said Ulric Ljungblad, CEO of Freemelt. “We are very pleased to see that our products will be used at one of the world’s leading synchrotron radiation facilities, as well as at Sweden’s largest technical research and learning institution.”

Business updates from Jellypipe and SLM Solutions

In business news, self-styled 3D printing ecosystem Jellypipe has announced the addition of U.K. provider AMufacture’s services to its online platform. The companies’ collaboration enables Jellypipe to continue growing its British profile, while allowing AMufacture to market its CNC machining, injection molding and generative design offerings to a new European client base.

“We are always looking to extend our reach, and integrating with the Jellypipe AM ecosystem enables us to leverage into a new sphere of clients, and deliver a service that will grow as we do,” said Will Howden, COO of AMufacture. “This is an exciting time for AM, and to be on the ground floor with Jellypipe in the UK we view as a huge opportunity.”

Elsewhere, in financial affairs, German 3D printer manufacturer SLM Solutions has issued a second tranche of 2% convertible bonds worth around €15 million. The backing of the firm’s largest shareholder Cornwall GmbH and its advisory firm Elliott Advisors, mean that the move is likely to be passed imminently, with funding set to be available from April.

According to SLM, it intends to use the investment to finance both the R&D of its next-gen machine, and the expansion of its sales network. However, the announcement also follows a protracted takeover saga in 2017, in which GE were put-off the company’s purchase by Elliott Advisors’ asking price, and SLM appears to be reeling from the continued aftershock of these events.

CoreTechnologie’s software update

Engineering software developer CoreTechnologie has released a comprehensive update for its 3D_Analyzer CAD analysis tool. The revamped program allows users to rapidly add 3D annotations via automatic presets that are configured to predefined geometry differences, while enabling quick model comparisons via an easily-identifiable highlighting tool.

The overhauled application also features enhanced compatibility, allowing users to save files in either the JT, STEP 242, 3D PDF or native 3D_Analyzer format. As a result, engineers are now able to highlight and export their models quickly and easily to external partners, who in turn, can benefit from enriched product previews that include more detailed information.

NASA makes electronics advance

The NASA Marshall Space Flight Center has made significant advances in the R&D of Electronic Alchemy’s eForge 3D printer. As part of a $1 million Small Business Technology Transfer (STTR) contract, Dr Chance Glenn and Alchemy’s engineers have developed six novel materials that are specifically optimized for the machine.

Using the filaments, it could now be possible to 3D print electronics on-demand, including switches and solar cells that can be combined into more complex circuits and computers. In future, the researchers intend to develop more materials, with the aim of rolling-out the technology at universities, and enabling more innovative R&D to take place there.

According to Marshall engineer Tracie Prater, the eForge has potential orbital applications, but they require further development. “Currently the paradigm is that everything that’s used in space gets launched from Earth,” said Prater. “When you’re looking at analyses for long-duration missions, the logistics requirements become, in some ways, prohibitive.”

Encouraging future female engineers

Finishing this week with an educational update, software firm Gen3D is making a final call for people to sign up to its online ‘Design for Additive Manufacturing’ course. Funded by British technology accelerator Innovate UK, the program is designed to help upskill people who are out of work or on furlough due to COVID-19.

The five-part course, which is run by experienced academics and experts, includes five design tutorials, multiple industry test cases and three hours of related video content. From April onwards, the course will no longer be free of charge, and Gen3D is encouraging engineers to take advantage of the offer while there’s still time.

“One of the biggest challenges in the uptake of additive manufacturing globally is the ability to design optimised parts for the process,” said Wesley Essink, CTO of Gen3D. “Extensive DfAM knowledge has been created, however, this is often locked up in academic journals or kept as proprietary knowledge within large organisations. Gen3D changes this.”

Last week also marked International Women’s Day, and there have been several recent announcements regarding increasing the involvement of young women within the industry. U.S. accelerator America Makes, for instance, has partnered with the Girl Scouts of America (GSUSA), to promote STEM education through additive manufacturing.

Working together, the organizations intend to create a playbook for integrating 3D printing into scout programming, which in turn, will be used to hand out the first ever AM patch. The ‘MFG patch’ is set to be earned through engagement in the areas of design, manufacturing and post-production, while tying into the broader scouting badge set-up.

“The Girl Scouts are dedicated to building skills and interests in STEM—fields that unfortunately reflect great gender disparity,” said Josh Cramer, America Makes Education & Workforce Director. “Girl Scout programming is specifically designed to reverse this trend and promote STEM, ensuring K-12 girls are empowered to pursue STEM-related fields and compete successfully for these positions.”

Similarly, the winners of Innovate UK’s Women in Innovation Awards have now been announced. A total of forty successful female entrepreneurs from across the UK were recognized at the event, including Anja Stolte, who set up Enabling Manufacturing, a dedicated 3D printing firm that works with international clients in the marine, rail and aerospace industries.

Finally, Dutch 3D printer manufacturer Ultimaker has partnered with America Makes to donate more than twenty of its 3D printers to young women in schools around the U.S. The machines have been contributed as part of the broader ‘Additive Edge’ program, which is designed to encourage female students to take-up additive manufacturing courses.

“We want to add sustainable value as a company, and foster an environment of equity that enables the next generation of female engineers to leverage 3D printing and solve the world’s challenges,” commented Greg Elfering, President of Ultimaker America. “Together we can make it happen.”

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our Facebook page.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Ultimaker’s ‘Maker Girls’ in 2016. Photo via the University of Illinois.