Metal 3D printing company Norsk Titanium has announced closing a significant investment from Triangle Holdings, affiliates of Fortress Investment Group.

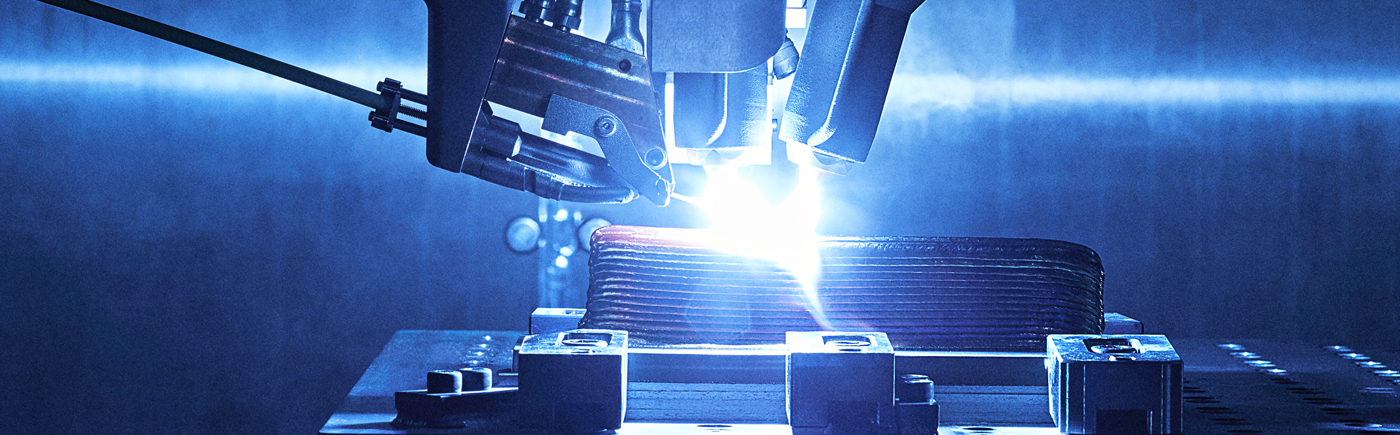

While Norsk Titanium has not disclosed the exact figure, Triangle Holdings has invested over $1.2 billion in the aerospace industry since it was formed in 2011. Norwegian company, Norsk Titanium 3D prints titanium with its proprietary Rapid Plasma Deposition (RPD) process that combines melted wire feedstock, with argon gas and plasma torches.

Applying the investment

Norsk Titanium will use the investment from Triangle to further advance the company’s manufacturing capabilities and expand 3D printing applications for the aerospace industry. Currently, Norsk Titanium operates out of its $125 million Plattsburgh facility in New York which plans to expand by the end of this year. At the Plattsburgh plant, Norsk Titanium 3D prints titanium with the Rapid Plasma Deposition (RPD) process contained in Merke IV machines.

Jeremy Barnes, partner in Triangle, explains this investment reflects the group’s “strategy of investing in game-changing businesses across the aerospace sector. We look forward to working with Norsk Titanium on proliferating its RPD™ technology.”

Norsk Titanium President & CEO Warren M. Boley, Jr. believes his company is perfectly positioned for the future of industry,

The fourth industrial revolution is being designed by corporations and individuals who display great vision and bold execution, and I am immensely proud to add Fortress as a partner on this ambitious journey.

Aerospace application

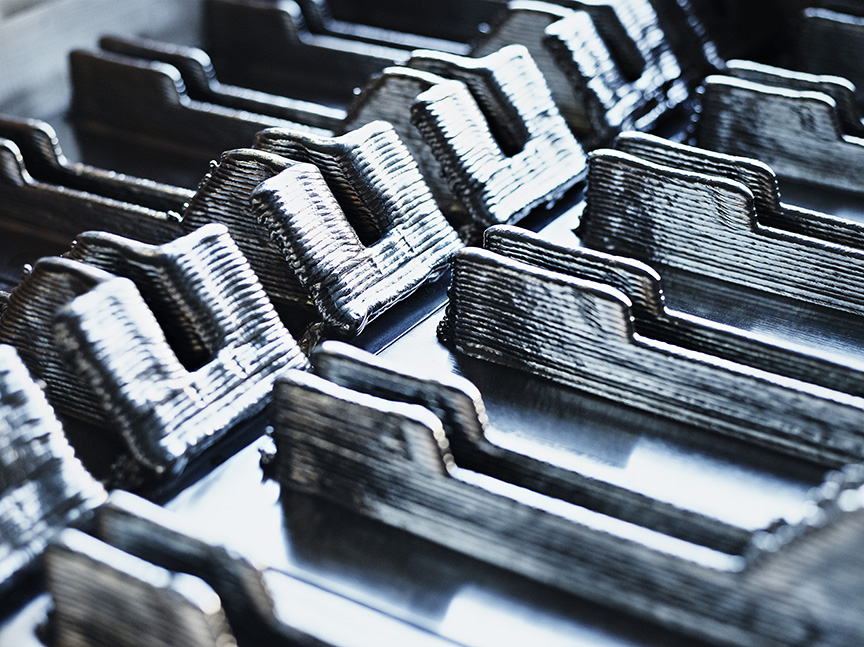

Norsk is currently concentrating its business on the aerospace industry as it in this sector the company believes the potential of its technology can be fully realized. According to Norsk, 3D printed titanium provides a more cost-effective production method for strong and lightweight components. The additive manufacturing business recently announced it will supply aircraft manufacturer Boeing with 3D printed titanium structural components for the Boeing 787 Dreamliner.

Norsk Titanium Chairman of the Board John Andersen, Jr. explains how the investment from Triangle will expand this current application and the company’s business as a whole. He states the strategic investment “allows Norsk Titanium to extend our Rapid Plasma Deposition™ capability fully into the commercial aerospace sector and beyond that- and accelerates its revolutionary changes to metal manufacturing process forever.” Andersen, Jr. also states that “the ambition demonstrated by this strategic investment will bring Norsk Titanium’s customers unprecedented application opportunities.”

Norsk will demonstrate its aerospace applications for additive manufacturing at this year’s Paris Air show. On display will be the 3D printed Dreamliner parts as well as a mock-up of the pioneering machine that produced them, the Merke IV. A number of other 3D printing companies will be joining Norsk at the event to demonstrate the growing applications of 3D printing in this industry, these include British company Renishaw and Stratasys.

For all the latest 3D printing news, subscribe to the most widely read newsletter in the 3D printing industry, follow us on twitter and like us on Facebook.

Featured image shows the Rapid Plasma Deposition process taking place. Image via Norsk Titanium.