Engineers from McMaster University in Hamilton, Canada, have developed a 3D bioprinting method using magnets to rapidly produce cell clusters.

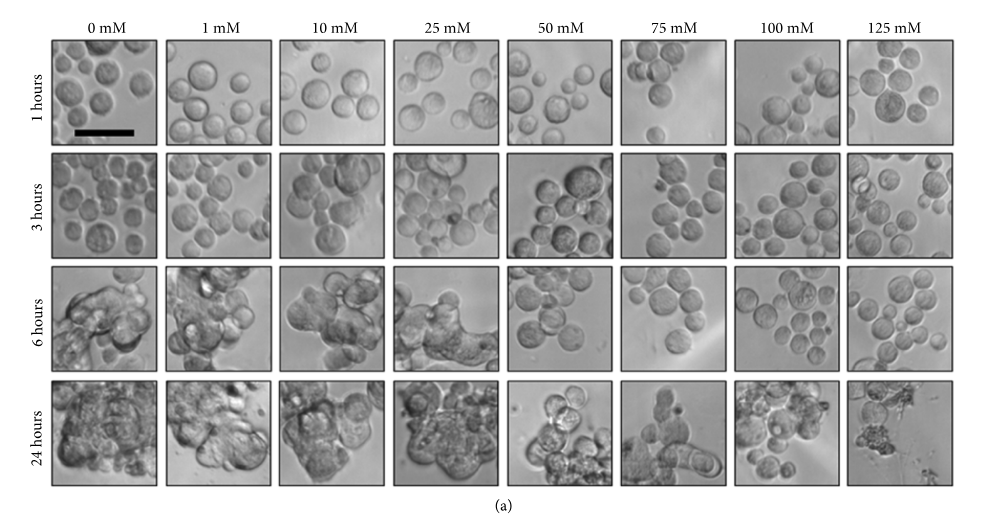

With formulated bioinks comprised of human breast cancer cells and magnetic salt hydrate, also known as Gd-DTPA, a magnetic field is applied, displacing the cells to a fixed area which “seeds” the formation of a 3D cell cluster.

In a study published in Research, a Science partner journal, the engineers use this method to 3D print cancer tumors within six hours. This process is designed to create an alternative laboratory environment mimicking conditions inside the body for regenerative medicine research – reducing the need for animal testing.

“We have developed a technical solution to overcome the current biological limitations and has the potential to accelerate tissue engineering and regenerative medicine technology,” said Sarah Mishriki, a Ph.D. Candidate at the School of Biomedical Engineering and lead author of the study.

“The ability to rapidly manipulate cells in a safe, controllable and non-contact manner allows us to create the unique cell scapes and microarchitectures of human tissues without the use of scaffolding.”

Accelerating regenerative research

Typically, 2D cell cultures grown in Petri dishes models are less likely to accurately interact than those produced in a 3D environment. 2D models also consist of animal cells which enable drug testing and the study of disease progression.

Ishwar Puri, a professor of mechanical engineering and biomedical engineering, led the McMaster team to develop a new method to rapidly print 3D cell clusters that can better mimic conditions inside the body without the use of animal cells.

This was done using magnetic fields and carefully arranged magnets, which controlled the volume of the cancer cell-laden bioinks. Using this method, the team was able to 3D print cancer tumors. Rakesh Sahu, a research associate, added:

“This magnetic method of producing 3D cell clusters takes us closer to rapidly and economically creating more complex models of biological tissues, speeding discovery in academic labs and technology solutions for industry.”

The researchers hope this method will lead to faster drugs tests using artificial human tumors which can foster breakthroughs in the treatment of cancer and tissue engineering.

“Rapid Magnetic 3D Printing of Cellular Structures with MCF-7 Cell Inks” is co-authored by Mishriki, A. R. Abdel Fattah, T. Kammann, R. P. Sahu, F. Geng, and I. K. Puri.

Voting for the 2019 3D Printing Industry Awards is now open. To see if your nominations made the shortlist, and to help decide this year’s winners, cast your votes now.

For more academic additive manufacturing research, subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Ishwar Puri, center, with his research team, Sarah Mishriki, Ph.D. candidate in the School of Biomedical Engineering and lead author, and Rakesh Sahu, a research associate. Photo via Jin Lee, McMaster University, Faculty of Engineering.