One of the key advantages that 3D printing offers over traditional manufacturing is that it takes manual skill out of the process of creating something. Using a robotic machine to produce an item gives a wide range of people the chance to manufacture goods, regardless of craftsmanship or even the physical ability to craft such an item in the first place. For instance, Evan reported a story about Raul who, though he couldn’t manually create one with his hands, was able to 3D print a wheelchair ramp for navigating unfriendly sidewalks. More recently, BBC News relayed the story of a program at Hereward College that is teaching students with disabilities to create CAD models to 3D print their own assistive items.

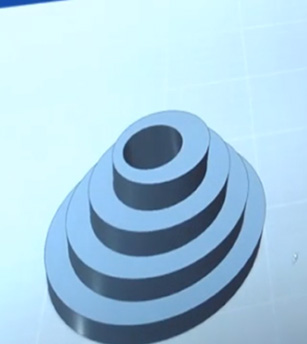

Through a collaboration between the Department of Computer Science at Warwick University[1] and Hereward College, a further education school[2] that enrolls many students with special needs, the ‘Engaging Young People with Assistive Technologies’ programme was born. Last summer, the Department of Computer Science hosted students from Hereward and guided them through the design of custom-tailored objects to tackle a number of problems the students faced with their environment, such as the wheelchair iPod mount pictured above. The objects were then 3D printed with a Cube X Trio, generously donated by 3D Systems. By designing their own assistive devices, the students were able to overcome obstacles faced daily, while also gaining a sense of empowerment.

One Hereward student, Ollie Baskeran, lives with muscular dystrophy, making some tasks difficult to manage. In the case of drinking from a soda bottle out of a straw, for instance, Ollie can have a hard time retrieving said straw when it inevitably falls into the bottle. To tackle this challenge, he designed a 3D printed straw holder that fits snugly over a soda bottle’s opening, while keeping the straw in place. The student was overwhelmed with the advantages 3D printing offers, saying, “you can literally think of something and a few minutes later, it is in your hand.”

Another student living with muscular dystrophy, Christopher Samuel, was able to manufacture the prototype for a personalized fork that would suit his needs perfectly. The prototype was printed in plastic, but it will be reproduced in stainless steel to extend its longevity. The ability to design and print such a useful item led Christopher to the conclusion that, “More people should have an opportunity to create something that’s tailor-made to their specific needs.”

In the next term of the project, the students will be designing more complex objects to assist them. Warwick researcher, James Atkinson, suggests that, in the future, other technologies may be incorporated into the program, including robotic hands and gesture control devices, such as the Leap Motion Controller.

Source: BBC News

[1] By the way, Warwick University’s Warwick Manufacturing Group has the best promo video. I can’t embed it, but go over to their site if you want to see cool technology overlayed with some sweet beats that, while they approach dubstep, are too good to be classified as such.

[2] Continuation school for US readers.