Composite materials are leading the way for high-performance 3D printed prototypes. In tooling, electronics and automotive industries, businesses require materials that can withstand industrial-grade thermal, tensile and pressural tests.

Owens Corning, a leading supplier of glass fiber for composites, has developed the XSTRAND™ line of fiberglass 3D printer filaments to fulfil manufacturing’s demand for functional prototyping. For use in FFF/FDM 3D printers, the XSTRAND™ line is “Redefining additive manufacturing performance” with strength and resilience above carbon-fiber filled ABS, neat PP and standard PA6.

Currently available in two key engineering polymers, GF30-PP and GF30-PA6, the range of Owens Corning 3D printing filaments are available from US-based distributors including IC3D, iMakr and Ultimate3DPrintingStore.

Technical specifications of GF30-PP filament

GF30-PP is a reinforced polypropylene filament with a 30% glass fiber content. This material exhibits high stiffness, and resistance to varying temperatures, chemicals and UV light.

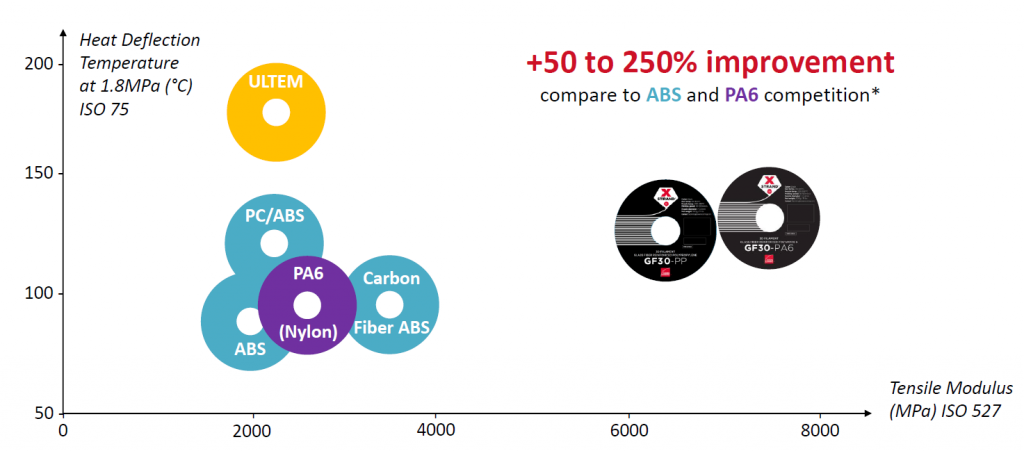

At ski equipment and outerwear manufacturer Rossignol, GF30-PP is essential to new product development. It has allowed the advanced research and development team to enhance prototyping efforts by demonstrating a 50% to 250% improvement on standard ABS and nylon-based PA6 materials.

Nicolas Puget, Advanced Research Manager at Rossignol, comments “A couple of years ago we started out using ABS filaments like everyone else in the sector: at best it was good for quickly making models, but it was not good for functional prototyping.”

GF30-PP can be used in all available FFF/FDM 3D printers, coming in standard 1.75 and 2.85 mm diameters, and either a 500 g or a 2200 g spool.

Mechanical Properties of GF30-PP

Tensile Modulus: 6 500 MPa

Tensile Strength (Yield): 60 Psi

Elongation (Break): 1.6 %

Flexural Modulus: 4 300 MPa

Flexural Strength (Yield): 83 MPa

Flexural Strength (Break): 78 MPa

Heat Deflection temperature: 120 °C

Technical specifications of GF30-PA6 filament

GF30-PA6 is a reinforced PA6 nylon filament, also with 30% glass fiber content. This material exhibits high strength and thermal performance. According to mechanical tests performed by Owens Corning, the material outperforms most of the PA6 products on the market today. GF30-PA6 has a stiffness and toughness typically between 50% – 250% higher than carbon fiber reinforced ABS.

Industrial tooling is identified as a key area of application for the material. Due to high wear resistance, it is ideal for use in a factory environment. It can be used as a replacement for steel in the fabrication of jigs and fixtures used in car assembly. It also dramatically cuts the cost of its traditionally metal machined counterparts, part turnaround time, and gives workshops the flexibility to make modifications on site.

GF30-PA6 has a wide operational temperature range between -20 °C to 120 °C ensuring performance in the most extreme environments.

As with GF30-PP, GF30-PA6 can be used in all available FFF/FDM 3D printers, coming in standard 1.75 and 2.85 mm diameters, and either a 500 g or a 2200 g spool.

Mechanical Properties of GF30-PA6

Tensile Modulus: 7 400 MPa

Tensile Strength (Yield): 102 Psi

Elongation (Break): 2.1 %

Flexural Modulus: 6 100 MPa

Flexural Strength (Yield): 170 MPa

Flexural Strength (Break): 166 MPa

Heat Deflection temperature: 124 °C

Buy XSTRAND™ GF30-PP and GF30-PA6 filament now to take your rapid functional prototyping to the next level. XSTRAND™ filaments work great on Ultimaker, Zortrax, Raise3D, 3NTR and many more 3D printer brands.

For more information about the XSTRAND™ materials range you can also contact Owens Corning direct at the following email: [email protected].

For more on the latest hardware, software and materials releases subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Featured images shows Owens Corning XSTRAND™ glass fiber reinforced 3D printer filaments are made for FDM/FFF functional prototyping. Image via Owens Corning