Cevotec, a fiber composite engineering firm headquartered in Munich, has signed a distribution partnership with Manufacturer’s Representation Firm Composite Automation, LLC. Under the terms of the agreement, Composite Automation, LLC will become the official representative for Cevotec’s unique Fiber Patch Placement (FPP) additive manufacturing technology across the US, Canada and Mexico.

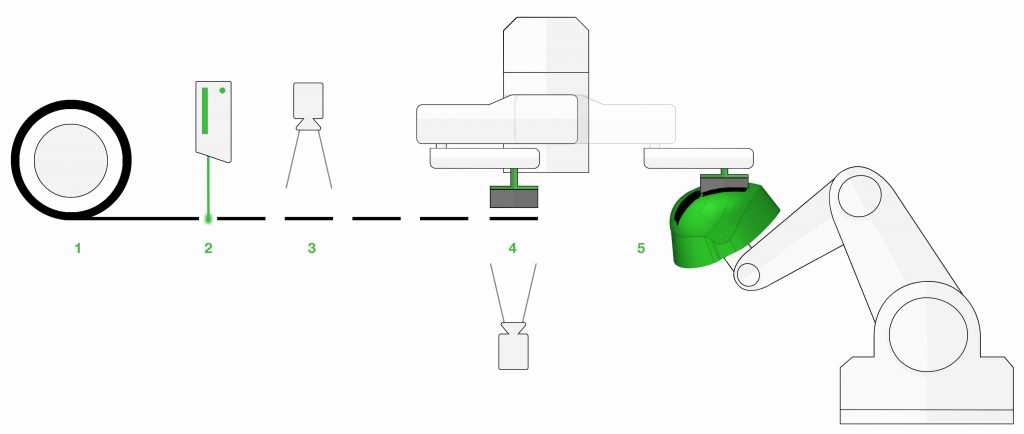

Pick and place Fiber Patch Placement

Fiber Patch Placement (FPP) technology is a robot operated manufacturing technique for making fiber composite objects. The technology is targeted at industrial use in aerospace, machining, medical, sports and automotive industries, e.g. for ski/snowboard reinforcements, helmets and lightweight car parts.

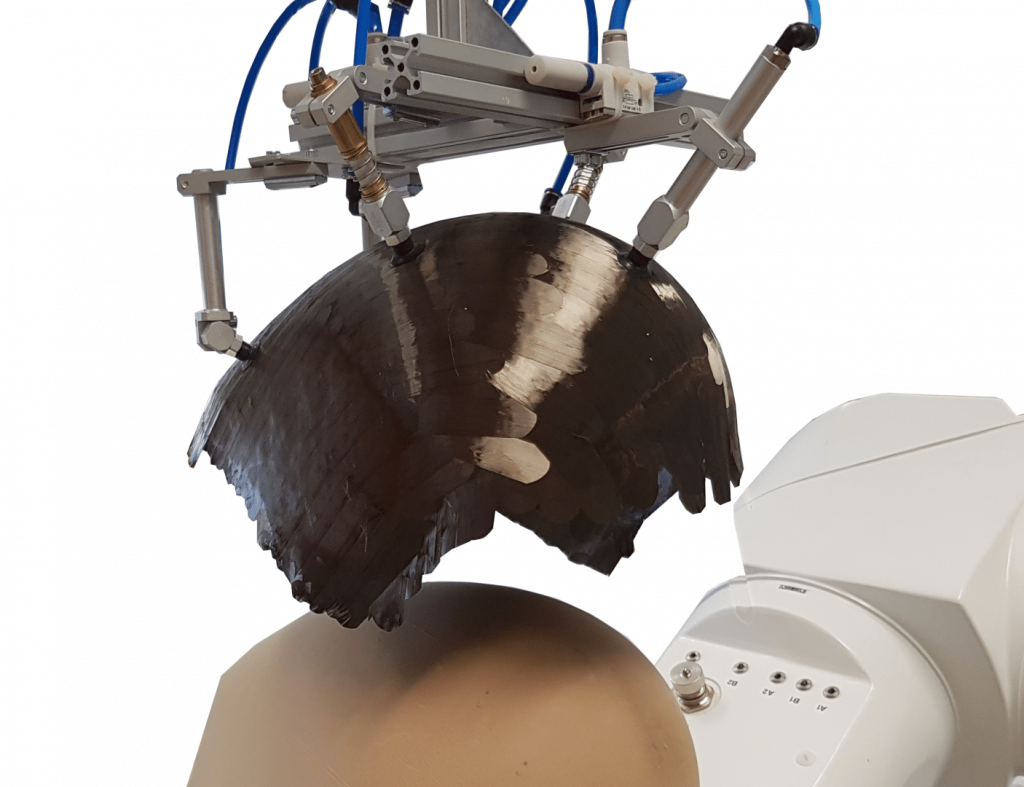

The process works by layering composite fiber patches (that look like scales) over a pre-fabricated surface, typically made of wood.

The patches are custom cut from a roll of fiber tape, inspected for quality, then picked and placed onto the pre-fab substrate by a gripper. The substrate is turned accordingly to ensure even and interlocking placement of each patch.

Completing the process, the finished object is removed from the substrate by a third robotic gripper.

A “truly disruptive” technology

Existing partners applying the FPP process include Airbus, and German mechanical engineering firm Baumann Automation. The partnership with Composite Automation, LLC is the result of positive feedback received at the 2017 Composites and Advanced Materials Expo (CAMX) held in Florida.

“We are very happy to have John Melilli and his team at Composite Automation to introduce the benefits of patch technology to every composite manufacturer in North America” comments Thorsten Groene, Managing Director of Cevotec GmbH.

“This technology is truly disruptive,” adds John Melilli, owner of Composite Automation, LLC, “From the design to the fabrication of the part, the complete process is managed by the Cevotec software and automation system.”

“The full properties of the part are known before the part is manufactured. Reliable throughputs and material usage are empirically understood. This data is part of the justification for a machine acquisition.”

Other approaches to 3D printing carbon fiber include composite-based additive manufacturing (CBAM) from Impossible Objects and the continuous carbon fiber 3D printing process from Markforged.

Vote for Innovation of the Year and more in the 2018 3D Printing Industry Awards. To be in with a chance of attending this year’s event, winning a 3D printer, and having your design 3D printed by Protolabs, enter the 3D Printing Industry Awards trophy design competition.

For more the latest 3D printing news – subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Featured image shows Cevotec’s Fiber Patch Placement (FPP) system. Photo via Cevotec