Maryland-based manufacturing company Xometry has just announced it has closed an investment funding round of $15 million.

We spoke to Xometry to find out more about the funding and how the company will use investment in its future operations.

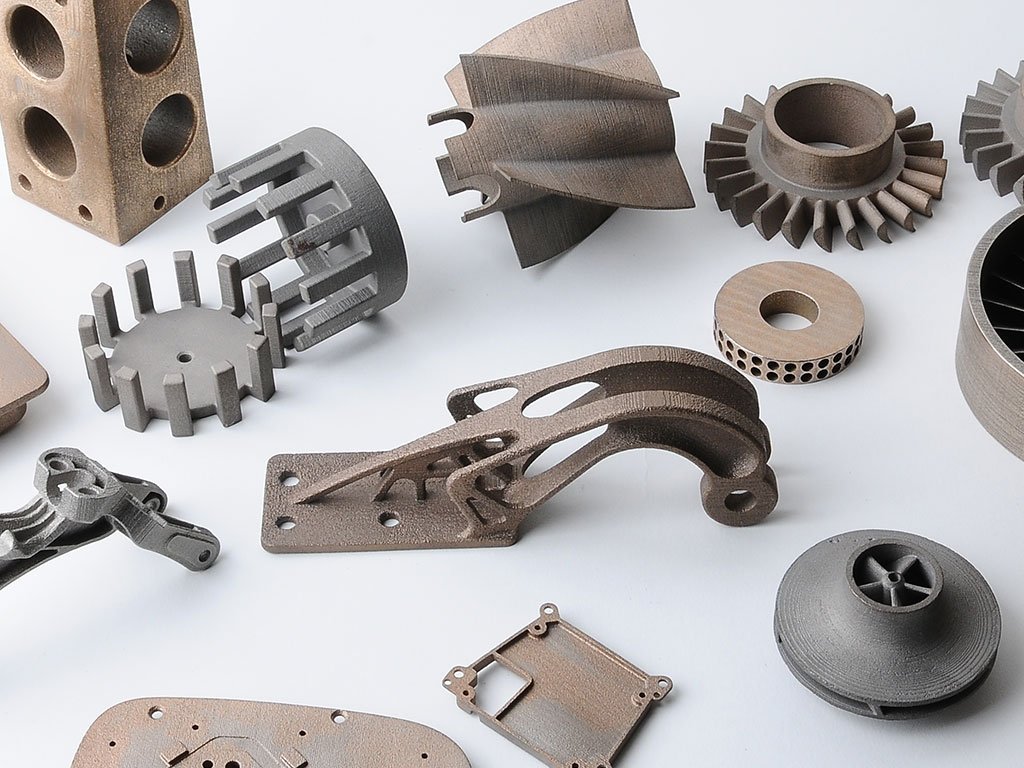

Xometry offers a software platform for on-demand manufacturing services using 3D printers as well as traditional manufacturing machinery. An instant quoting service connects users with smaller manufacturing shops in the U.S to fulfil the part orders.

Having raised $23 million earlier in the year, today’s news brings the total funding to $38 million. This recent round was led by BMW i Ventures with existing investors GE Ventures and Highland Capital Partners. BMW i Ventures and GE Ventures have both previously invested in several other notable 3D printing companies including Carbon and Desktop Metal.

Expanding the online platform

Randy Altschuler, co-founder and CEO of Xometry is “thrilled to partner with BMW i Ventures and deepen our relationship with General Electric.” Altschuler explains how the funding will be implemented in the business,

We’re accelerating our efforts to provide additional features to our online platform, making it easier for engineers and procurement managers to conveniently order a wide range of parts delivered by our expanding network of hundreds of manufacturers across the nation.

Market expansion

Xometry states the company has achieved rapid market expansion recently and expanded its customers past the 5,000 mark. We asked Xometry how the typical customer is using the company’s services,

Our customers use Xometry for a wide range of custom parts, from prototypes to production. Many of our customers are engineers at Fortune 500 companies like BMW and GE, and at government agencies like NASA and the U.S. Army.

The battle for the digital thread end-to-end platform

With a number of industrial companies looking to develop the ideal end-to-end software platform, and some even turning to blockchain systems, we asked Xometry how it is approaching the competitive field,

Manufacturing on demand is at the heart of the digital thread end-to-end platform, allowing engineers to create, prototype, iterate, and produce custom parts seamlessly. Xometry serves as a digital supply chain, incorporating quoting up front to give a market price and then appropriately matching each part with a partner in our nationwide manufacturing network.

Set apart from the rest

Xometry will continue to develop its on-demand platform with this funding and hopes to cement its position in this field. The company believes it is set apart from other services,

The combination of Xometry’s instant quoting platform and nationwide network of hundreds of machine shops and small manufacturers puts Xometry in a unique position in the manufacturing space. The ability to get an instant quote, lead time, and manufacturability analysis on your part in seconds by simply uploading a 3D CAD file has made ordering custom parts more efficient for engineers and designers.

To stay updated with all the latest 3D printing news, subscribe to the most widely read newsletter in the 3D printing industry, follow us on twitter and like us on Facebook.

Featured image shows array of on-demand parts. Image via Xometry.