New York-based 3D printing bureau, Voodoo Manufacturing has raised $5 million in investment funding to expand its operations in scale and automation.

The investment round was led by U.S venture capital firm General Catalyst, with investment also from NextView Ventures, 645 Ventures, and Y Combinator’s continuity fund. Having raised $1.5 million earlier this year, Voodoo now intends to double the size of its production base, massively scale up automation processes and has ambitions to take on injection molding.

We spoke to the team at Voodoo Manufacturing to find out more about their plans for the future.

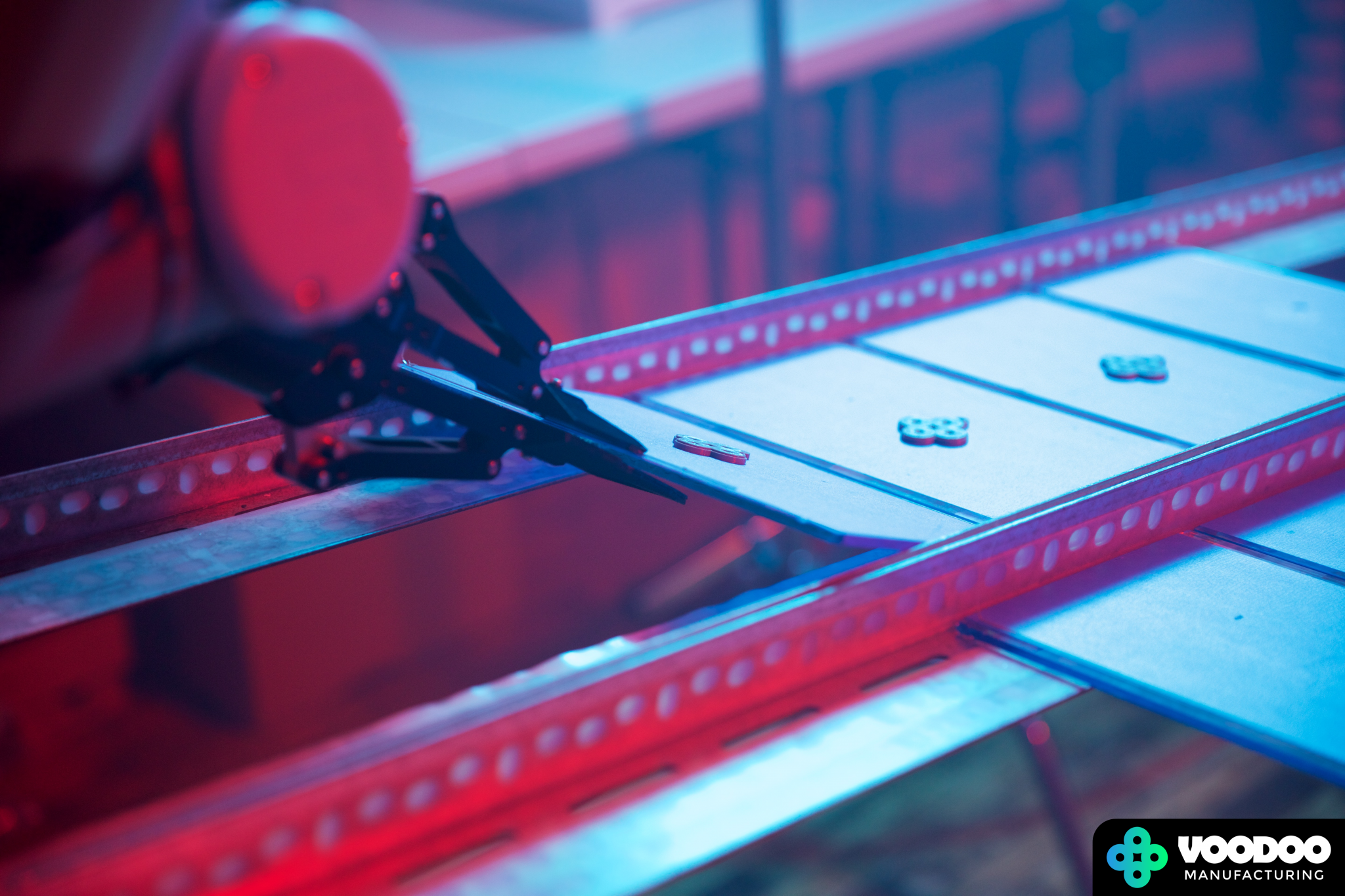

Gif shows Voodoo Manufacturing’s Project Skywalker.

Reducing costs and scaling up

Voodoo Manufacturing currently operates a factory farm of 3D printers using a combination of proprietary software, autonomous robots and human workers.

We are building a digital factory that can accept any digital 3D file, and produce thousands of physical products without any labor or startup costs, and in incredibly short lead times. Making this possible comes down to reducing our costs through automation, and increasing our capabilities to expand into larger and larger markets.

In the short-term future, the company explains, “we have two main goals in the next three years: introducing robotics and software automation to reduce our costs and make the factory more scalable, and expanding into new markets with new materials, [and] capabilities.” Currently the company uses Makerbots for its production but suggests this will expand in the future.

Voodoo believes that with the new funding it may be able to tackle the injection molding market. Voodoo currently operates within the sub-10,000 units market,

However, the fact remains that the majority of today’s world-wide part production is for runs of greater than 10,000 units. Therefore, to make our manufacturing method a more viable alternative to injection molding, we must offer the ability to scale beyond 10,000 units and still compete for price.

As a first step towards these goals Voodoo explained to us, “we need to hit 100,000 units as our next milestone. In order to do that, we’ll need to cut costs by an order of magnitude.”

Further automation

Voodoo Manufacturing reveals it intends to reduce costs by 90% over the next three years by further automating its manufacturing process. The 3D printing bureau has already explored this avenue with its Project Skywalker. The prototype system was unveiled in March and allows the company to operate its 3D printers with a robotic arm. By doing so, it removes the need for manual removal and loading of the build plates.

While further automation of the 3D printing system will save the company costs, it may receive backlash for the impact upon jobs. However, Max Friefeld, co-founder and CEO of Voodoo Manufacturing addresses this as he says,

The truth is, as AI-enabled robots become more capable and collaborative, there will be new demand for jobs that require human skill-sets, like system maintenance and customer support. This will redefine what it means to be a factory worker and we’re excited help make the United States a hub for manufacturing innovation once again with the help of our amazing investors.

For all the latest 3D printing news, subscribe to the most widely read newsletter in the 3D printing industry, follow us on twitter and like us on Facebook.

Featured image shows a wall of 3D printers. Image via Voodoo Manufacturing.