Big news from Carbon 3D! They have just announced funding of $81 million from new strategic investors GE Ventures, BMW, Nikon and JSR. Along with existing investors, they will work towards ‘bringing additive technology to more customers transitioning from prototyping-only use cases, to applications requiring final production quality parts with great surface finish, broad and expanding material options and the plans to transition to mainstream manufacturing’. Carbon also plans to offer its proprietary CLIP technology internationally and is accelerating production to meet worldwide demand for its M1 printer.

The expansion of Carbon is supported by the new funds, as well as pre-existing investments, bringing Carbon’s funding total to $222 million. More details of additional strategic investors involved in this round of financing will be announced in 2017 along with details of their manufacturing projects that utilize Carbon’s technology.

“3D printing is a translation of the digital to a physical reality and when done right, offers true design freedom across every category,” said Dr. Joseph M. DeSimone, CEO and Co-Founder of Carbon. “At launch we set forth a bold vision to fundamentally change how the world makes ‘things.’ We have been working to deliver on that vision for the U.S. market, and are ready to step onto the global stage.”

“In today’s digital world, additive manufacturing is changing how products are designed, made and serviced at GE,” said Steve Taub, Senior Director of Advanced Manufacturing, GE Ventures. “Carbon’s CLIP technology can print exceptional quality parts for end-use production, opening the doors to incredible possibilities like low volume manufacturing, freedom of design, and mass customization. We are excited to work with Carbon as part of our vision in deploying additive manufacturing applications across GE.”

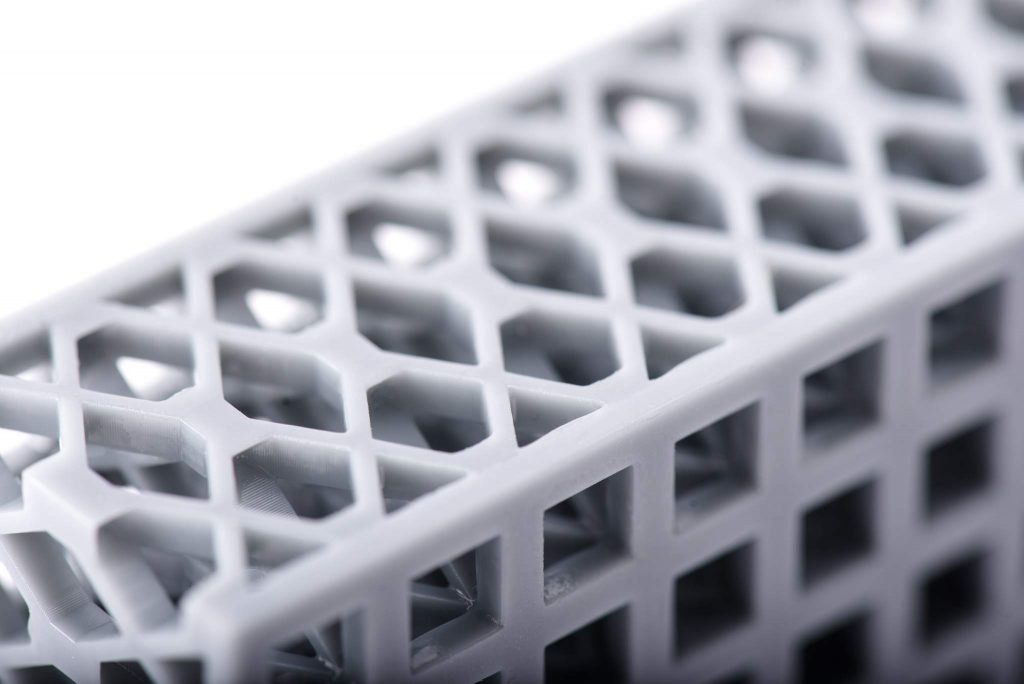

Carbon has been pushing the boundaries of 3D printing since the launch of the M1, their first machine. They were the first to produce 3-dimensional isotropic parts with the mechanical properties and surface finish of a quality that matches injection-molded plastics. Through collaboration with world-class manufacturing companies and service bureaus, Carbon have been able to deliver final quality parts for customers in many different industries. Carbon’s customers include BMW Group, Delphi and Ford.

Series C participants Nikon Corporation and JSR Corporation are exploring synergies making Carbon’s technology available in Japan as well as entry into other Asian markets. Nikon will bring their deep expertise in metrology and 3D data profile, including 3D measurement and X-ray CT. JSR, an important producer of fine chemicals associated with the manufacture of microelectronics, is an ideal partner to enhance exploration of new materials and extension of Carbon’s supply chain.

“We’re excited to partner with the innovative Carbon team to explore opportunities for Japanese and Asian expansion,” said Masao Nakajima, Senior Vice President of Nikon Corporation. “In addition to bringing fundamental scientific advances to 3D printing, the company has executed relentlessly, putting its M1 machine into the hands of customers, and continuing to innovate on their machine, software, and resins.”

“The current 3D printing market, with the exception of very few, is a prototyping market,” said Nobu Koshiba, President of JSR Corporation. “Carbon approached the challenge, and potential, of 3D printing from a very different perspective. With its M1 and CLIP technologies, Carbon has introduced a solution that will truly revolutionize manufacturing.”

About Carbon

Carbon, a Silicon Valley based company, was founded in 2013. Working at the intersection of hardware, software and molecular science, Carbon is delivering on the promise of 3D printing, allowing commercial customers to go beyond basic prototyping to achieve 3D manufacturing. Continuous Liquid Interface Production technology (CLIP) was introduced simultaneously at TED 2015 and to the scientific community on the cover of Science Magazine (Science, March 2015).