SXSW Interactive has no shortage of hype. Words like “ninja,” “rockstar,” “thought leader,” ” game changer,” “visoniary,” and many more are tossed about like a football in a Tommy Wiseau film. Now, there’s nothing wrong with enthusiasm, but spending SXSW seeking for a herd of deeply philosophical ninjas carrying Fender Stratocasters and megaphones isn’t necessarily going to be the most productive use of time. In the end, content has to count for something. There has to be some way to cut through the hype.

The good people of Voxel8 came to SXSW to disparage the myth that 3D printing is for trinkets. Now, there is a whole lot of hype spurred at SXSW by people talking about how “3D printing is more than just those printed Yoda head trinkets.” Because I am terrible, I just keep thinking that I need a couple more Yoda heads for my collection–nevertheless the point does stand. For the technology to progress and be accepted as part of a truly innovative future, we must look to application and relevancy of innovative usage. The transition from trinket to tool requires focus and keen examination and it seems as though Voxel8 has it, with the experience and connections to back it up.

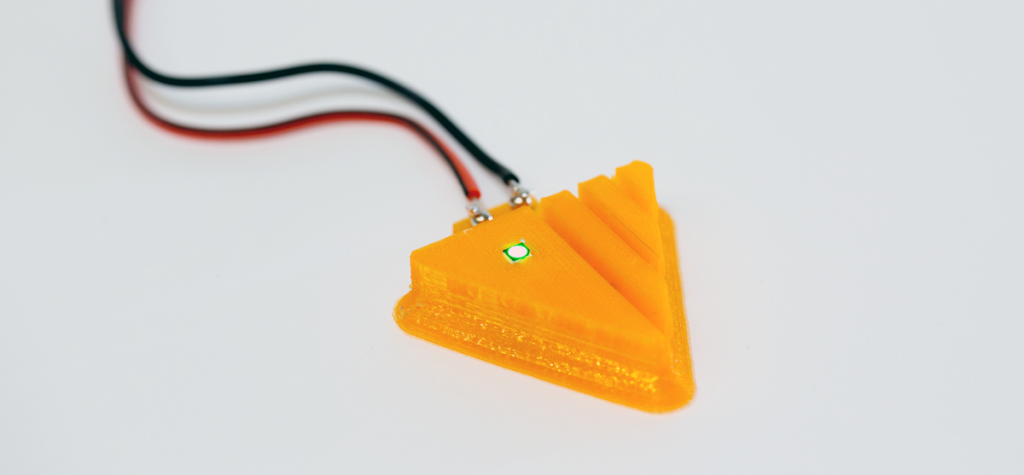

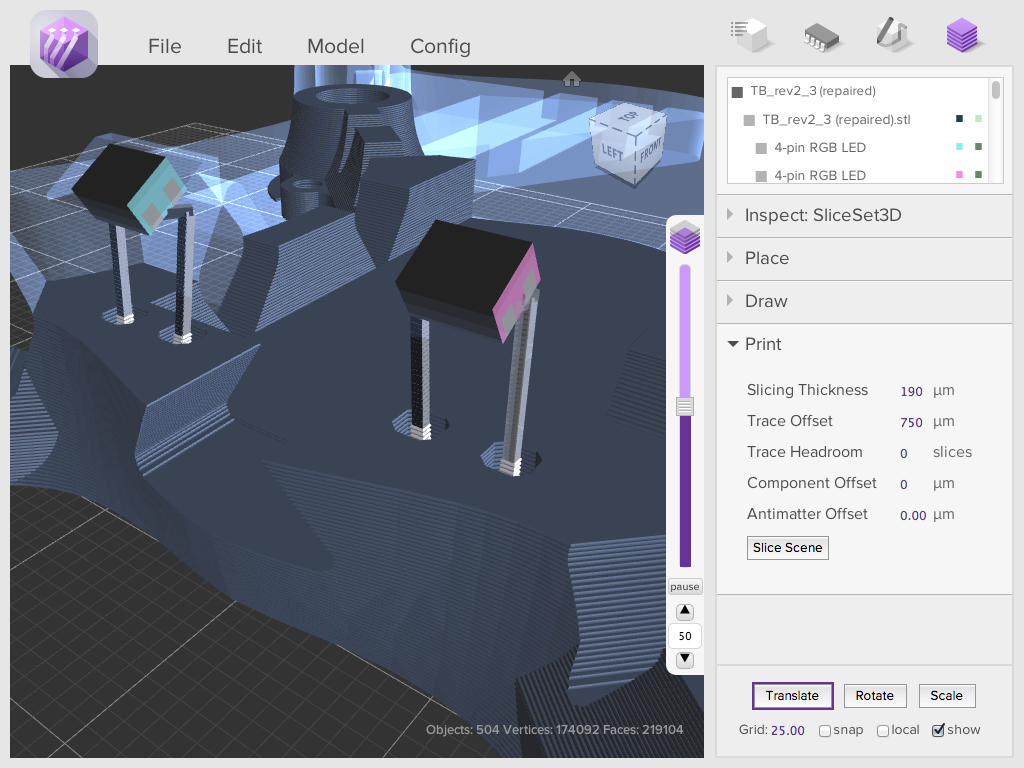

Voxel8 hit the CES floor running when they introduced their “developer’s kit,” which is designed to get their particular innovations in the hands of inventors, so that more people can start 3D printing integrated circuitry. They focus on “new functional materials with a novel 3D printing platform“ so “you can co-print matrix materials such as thermoplastics and highly conductive silver inks enabling customized electronic devices like quadcopters, electromagnets and fully functional 3D electromechanical assemblies.” Additionally, Autodesk is developing Project Wire, a Spark-Powered design tool for creating 3D printable electronic devices, made in conjunction with the Voxel8 3D printer.

Using the ever-so-convenient SXSW social function, I was able to contact Michael Bell, co-founder and hardware lead at Voxel8, and learn a little more about where they are going with their trinket killing endeavor. We are sitting on the second floor of the JW Marriot. It’s the best floor, on account of it the fact that it has a Starbucks and many wall sockets (the unofficial scavenger hunt at SXSW). He is a genial fellow, just in town for a few days to make this presentation and conduct SXSW business. Then it’s off and away. No party time here.

Laura Kobylecky: What are your newest innovations. What are you bringing to the table that differentiates your company?

Michael Bell: We have a conductive silver ink and that is a primary driver in the electronics area right now… It’s a conductive silver ink that prints and dries at room temperature, is highly conductive and has excellent adhesion to different materials like plastics epoxies. It can span gaps of fairly large distances. There’s no other material like it on the market… That’s primarily what we bring: “we have functional materials.”

LK: What are you most excited about doing with this?

MB: There’s a lot of spaces that 3D printing has just started with conductors… Most antennas are planar – have to be printed on some flat object and the [radio frequency] properties are degraded because of that. If you can truly 3D print an antenna – which we have shown on the research side, which we have done on the Voxel8 side – then your RF properties are significantly greater. You can integrate 3D antenna inside of cell phone cases, you can put them into laptops, you can put them into military kinds of applications. And that goes into another application, which is: printing wearable tech devices, so things like hearing aids.

About 98% of the hearing aids today which go inside the ear are 3D printed because they have to conform to every person’s ear. And after it’s printed they have technicians shove in electronics – they wire it up, they solder it, they close it, they sand it, etc. We think we can do that entire process in one chain, with no technician involved. Kind of making it so hearing aids can be made anywhere in the world instead of in some specialized location.

LK: Integrate electronics so that they might be more suited to the individual using them?

MB: Yes

LK: In the future, how will this change the way we approach building objects?

MB: The engineers, the designers, are very limited by current manufacturing mechanisms, which are injection molding circuit boards. With our process it’s economical to make more unique designs and iterations. Before they had to be more conservative. The final product can be 3dDprinted; it doesn’t have to go through this injection molding route. Instead of a lead time of months, the time from prototype to manufacturing can be days.

LK: So, there are more creative possibilities and faster to market?

MB: Much faster to market!

LK: What are you about to release?

MB: We’re finishing the developers kit printer, the one that launched January at CES. We’ve taken pre-orders since January. We’re working on finalizing manufacturing and then releasing that. So, there’s a lot of things on the software side that we’re working on. Well that, obviously, can change while hardware is being made because that had to be locked down much sooner than software.

LK: Way, way in the future, what is the potential for integrated machines and soft robotics? Where does your imagination take you?

MB: Soft robotics I almost think of as accessories that you can put on yourself that enable you to go faster or sensors that monitor every part of your body, so that you get a lot more detailed response time. All that [wearable tech] needs to be flexible.

LK: So, if awareness drives adoption, maybe killing trinkets but keeping a few around?

MB: It’s the adoption that will drive the speed that manufacturers make the machines.

LK: What differentiate you as a company? What is the “Voxel8 way”?

MB: It’s materials, an extremely strong background in printed materials and talent that no other company has. There is new hardware, but you see no one with novel materials out there – novel materials coupled with the process to combine them together.

LK: And it was the materials that brought Autodesk to you?

MB: Yeah. They bring the software. I’ll show you image…

[MB shows LK an image of silver squiggles layered neatly in a rectangle each squiggle no wider than a line in the palm that holds it.]

It’s pretty small and highly conductive. These are the properties of the silver ink, this [image of silver spanning a gap] is a centimeter gap and it spans the gap. These are just mechanical properties, they are also highly conductive. Our goal for us is to enable new designs, release our materials and let people use them for who knows what. We would like to say, “Here’s a hundred different materials, electrical properties, mechanical properties. We don’t really want to dictate. We want to see what applications come out that are extremely interesting and unique. That’s why we have the developers kit, to see what people use it for – what things we should focus our attention on.

It ships in q4 with dispensation systems for silver ink, dispensation systems for epoxies, silicon. Swapable upgrades for materials we release in future. It’s more like a cartridge system than a fixed head.

LK: Anything else you want the public to know?

MB: The fact that these are truly novel materials. Pneumatic dispensation. The air compression system, air pressure behind a syringe filled with silver, allows us to swap in whatever material we want. This eventually allows customers to put in their own materials That’s not that common. There are a wide range of materials that don’t have to be heated.

Overall, Voxel8 has soundly refuted the idea that 3D printing exists solely for 3D printing trinkets. In reality, they are innovating and inventing the tools of the future. And, it’s not too late to start doing so yourself, as the pre-order for the developer’s kit is still alive and kicking.