The Dutch phrase “Vorm Vrij” means Free Form, as in the capability that 3D printing has for creating any kind of shape. Dutch start-up Vorm Vrij wants to give 3D printing even more freedom through their LUTUM family of clay-based 3D printers, which replace plastic filament with more durable ceramics (once they are sintered in an oven) and then further expand this possibility through a dual ceramics extrusion system, or dual “clay struder”.

Marlieke and Yao, the designer duo that created the LUTUM and founded Vorm Vrij, spent the first part of their lives learning about design processes and exploring Maghreb culture. They, then, used their experiences to create a 3D printer which could “produce with an immediately recyclable and locally obtained natural material”, effectively 3D printing “without loss”. “Our final products are durable. They can be used by our great-grand children. If left to the elements they remain functional for 5000 years without any harm to our natural environment,” they explained.

Clay is the first among many potential, more “noble” materials that, especially for artists and artisans, should be able to replace, or at least complement, the thermoplastic that is currently used and, although PLA is possibly one of the most biodegradable substances, often abused. The main issue with ceramics, as I have had the chance to observe, is that many current ceramics artists prefer to work without CAD software or digital technologies, while early consumer 3D printing adopters prefer the ease-of-use and immediacy of plastics.

However, there is no doubt that a vase, if you are able to take it home safely, is much more valuable in ceramics than it will ever be if made of plastics. Vorm Vrij believes that “the future of home manufacturing can transform the landscape of ceramics” and that this legacy, combined with the latest developments in 3D production techniques, “will have a profound impact and show our children the value of pottery while living the digital age.”

To fuel this objective they have developed a line of four clay 3D printers, which all have the same base and can print objects as large as 650x700x700 mm. The most expensive model, the LUTUM MAX-XL, also includes a double extruder, 2 extra large clay tanks, and one regular tank for €5,858, while the entry level LUTUM Original system runs €4.655. Smaller versions may follow in the future.

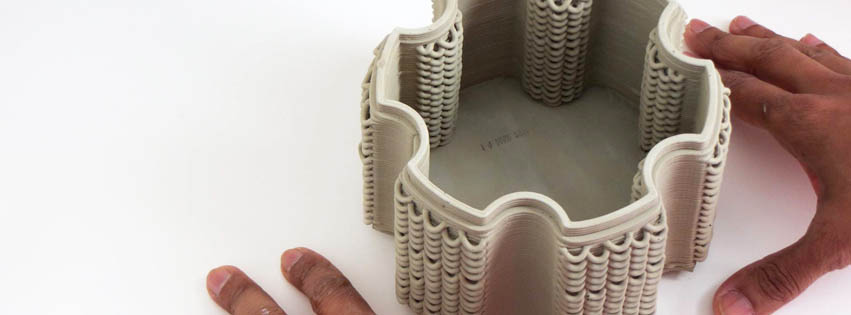

Judging by the photos published on Vorm Vrij’s website and social media pages, basic shapes created with the LUTUM technology are practically flawless, while more complex shapes could still be improved (a lot depends on the pumps settings and the clay mixture). The most revolutionary aspect of their cartesian technology, however, is the dual extrusion capability, which means that the 3D printer can actively control the calf’s flow and 3D print parts in a different color or in another type of clay altogether. This may hold several new possibilities, yet to be explored. And that is what happens with greater freedom.