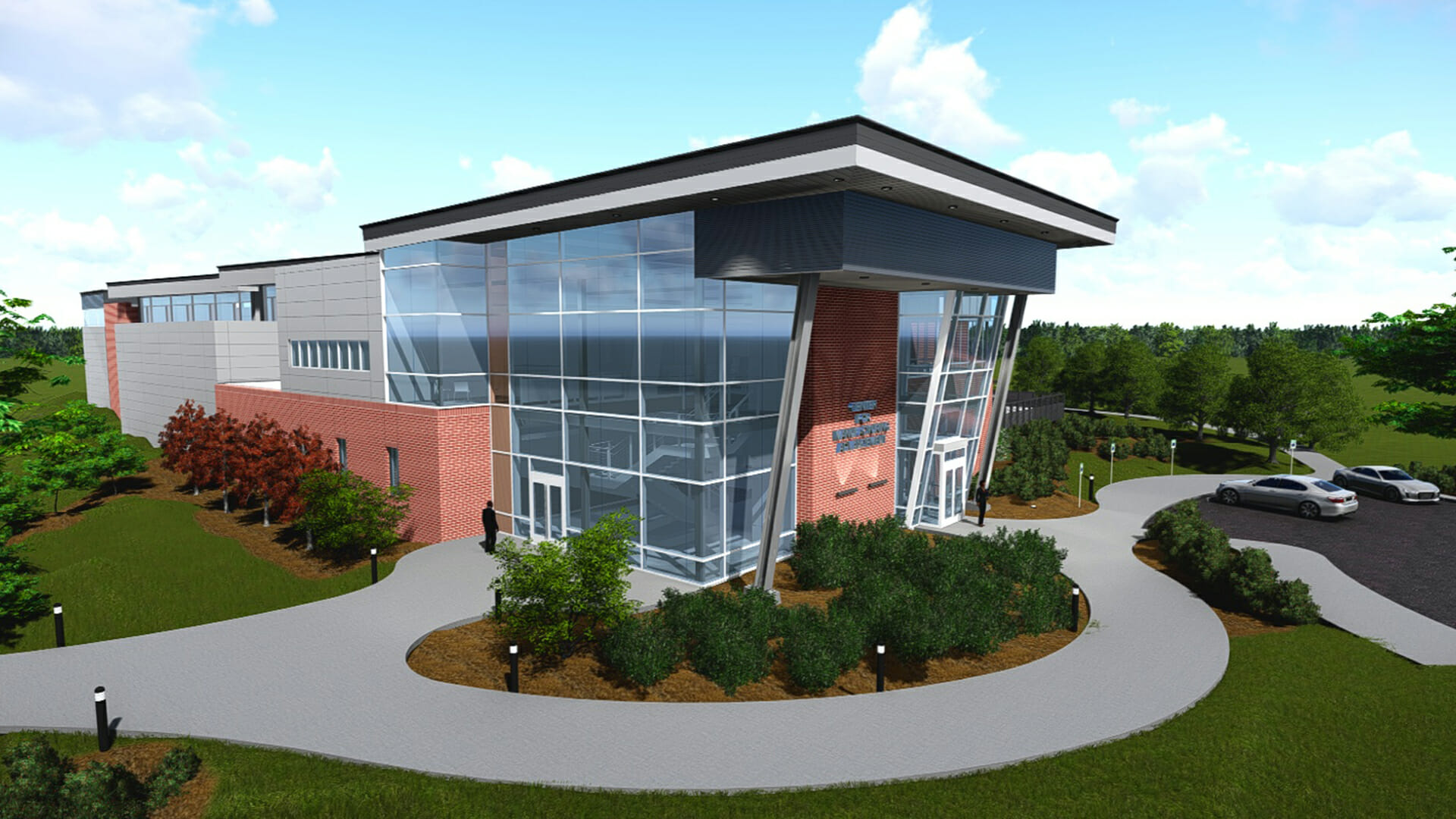

The Institute for Advanced Learning and Research (IALR) has announced plans to build a 51,250 square foot Center for Manufacturing Advancement (CMA) on its campus.

Projected to open in 2022, the $25.5M CMA will be funded by the Danville Regional Foundation and the State of Virginia, and is currently being built with the help of Virginia’s Division of Engineering and Buildings. The facility is ultimately intended to support manufacturing companies operating and expanding in the Southern Virginia area, all while enhancing the region’s manufacturing competitiveness, including via 3D printing readiness.

“Southern Virginia is a top location for advanced manufacturers from across the globe, and the Center for Manufacturing Advancement will undoubtedly help attract more of them to the region,” explained Governor Ralph Northam. “This state-of-the-art facility will play an important role in driving economic development and innovation in Virginia, while also helping the existing Danville-Pittsylvania business community grow and thrive.”

The Center for Manufacturing Advancement

The CMA, which is set to be adjacent to the recently established Kyocera SGS Tech Hub facility, will comprise two floors, offices, meeting rooms, and support service areas for its manufacturer tenants.

Furthermore, the Center will feature rapid-launch facilities designed to alleviate the initial down time often experienced by new businesses, and an ISO-certified inspection lab that companies can use to validate the quality of their products. IALR estimates that its inspection lab will reduce new companies’ start-up phases by up to six months, which is usually the time commitment required to certify an in-house inspection lab.

The CMA will also include process improvement labs and an industry 4.0-centric integration and training facility, which is where industrial 3D printing systems will be featured. The CMA will also house a collaborative innovation platform for the development of new manufacturing technologies, and even a concierge service to ease the transition period for companies new to the country.

Troy Simpson, Director of Advanced Manufacturing at IALR, added, “As technology exponentially advances, it is critical we stay at the forefront of integrating these innovations into training and manufacturing processes. Our new Center for Manufacturing Advancement will do just that – allow companies to interface with one another, technology providers and students to leverage space, collaboration and equipment opportunities for their own growth and advancement.”

Advanced manufacturing readiness in North America

With the Pittsylvania County Board of Supervisors targeting advanced manufacturing as a key component of economic development, the CMA will be utilized as a “solid resource” to aid the region in attracting and retaining job-creating companies. Manufacturing firm Phillips Corporation has already stated plans to locate its latest manufacturing solutions innovation center at the CMA building when it opens in 2022.

Alan Phillips, President and CEO of Phillips Corporation, concludes, “This commitment is a natural and continuing extension of our long-standing training and manufacturing technology collaborations with IALR. We believe there are substantial and immediate needs to develop additive and subtractive manufacturing technologies to support expansion of the USA’s manufacturing competitiveness as well as to strengthen the capacity and capabilities of our Defense Industrial Base.”

Back in October, industrial 3D printer manufacturer GE Additive commenced a Binder Jet public-private partnership with the Indiana Economic Development Corporation, Indiana’s lead economic development agency. Much like the CMA, the partnership is intended to help commercialize GE’s newly developed H2 binder jetting system, all while advancing Indiana’s wider manufacturing capabilities.

Elsewhere, in Pennsylvania, binder jetting OEM ExOne also announced the commencement of five similar projects with in-state universities to advance binder jet 3D printing technology. The R&D projects are all being funded through the Manufacturing PA Innovation Program set up by the Department of Community and Economic Development, and will provide work and capital to the educational institutions involved.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a rendering of the proposed CMA. Image via IALR.