Netherlands-based 3D printing start-up Veda 3D has launched the Veda Extrusion System (VXS), an extruder designed to significantly boost the material throughput of Fused Filament Fabrication (FFF) systems.

Thanks to its built-in blade wheel and fusion hotend, Veda 3D’s lightweight, compact, high-flow printhead is capable of reliably depositing over a kilogram of filament per hour, without any material slip. Compatible with most FFF 3D printers, the firm says that once installed, its extruder enables users to scale into the production of tooling, restorations, spares or custom parts.

Barriers to high-throughput FFF

Working from their base in the city of Rotterdam, the Veda 3D team specialize in developing ancillaries that make FFF 3D printers stronger, faster and more reliable. However, while the technology itself represents the most accessible and widely-adopted form of 3D printing, the firm says “a multitude of problems” prevent it being scaled into industrial applications.

FFF users seeking to raise their part throughput in this way, will likely have to increase their print speed, something that necessitates a rise in their system’s rate of material flow and printhead movement, but according to Veda 3D, “most machines are exclusively tailored to perform one or the other” of these tasks.

Another issue with extruding faster is that pushing molten plastic through a die or nozzle, requires a certain amount of force to overcome an internal friction known as ‘back-pressure.’ In the metal pinch wheel systems traditionally integrated into FFF 3D printers, if this force exceeds that exerted on the filament by the extruder, it can cause material in the mechanism to slip.

As Veda 3D points out, such slippage leads to under-extrusion, which in turn, impacts on the mechanical properties of parts produced, as they’ll suffer from poor layer adhesion. When these wheel systems slip, nozzle clogging is also more likely, as if too much filament is ground off in the process, extruders can dig in deep enough to get stuck, stopping prints in their tracks.

Veda 3D’s “industrial powerhouse”

As an alternative to tackling these issues via thinner filament or inductive heating, both of which can be expensive, Veda 3D has launched its new VXS. The extruder’s topologically-optimized melt zone enables it to achieve consistent fully-molten extrusion, regardless of nozzle size, while its 300W power output and high-tolerance heat block provide reliable heat transfer.

In an effort to bring FFF closer to injection molding, Veda 3D has also integrated a patented blade wheel into its extruder. The mechanism solves reliability issues and under-extrusion by ‘biting’ into the filaments fed into it, thus preventing any slip in the material, and allowing for the consistent flow of plastics at any feed rate.

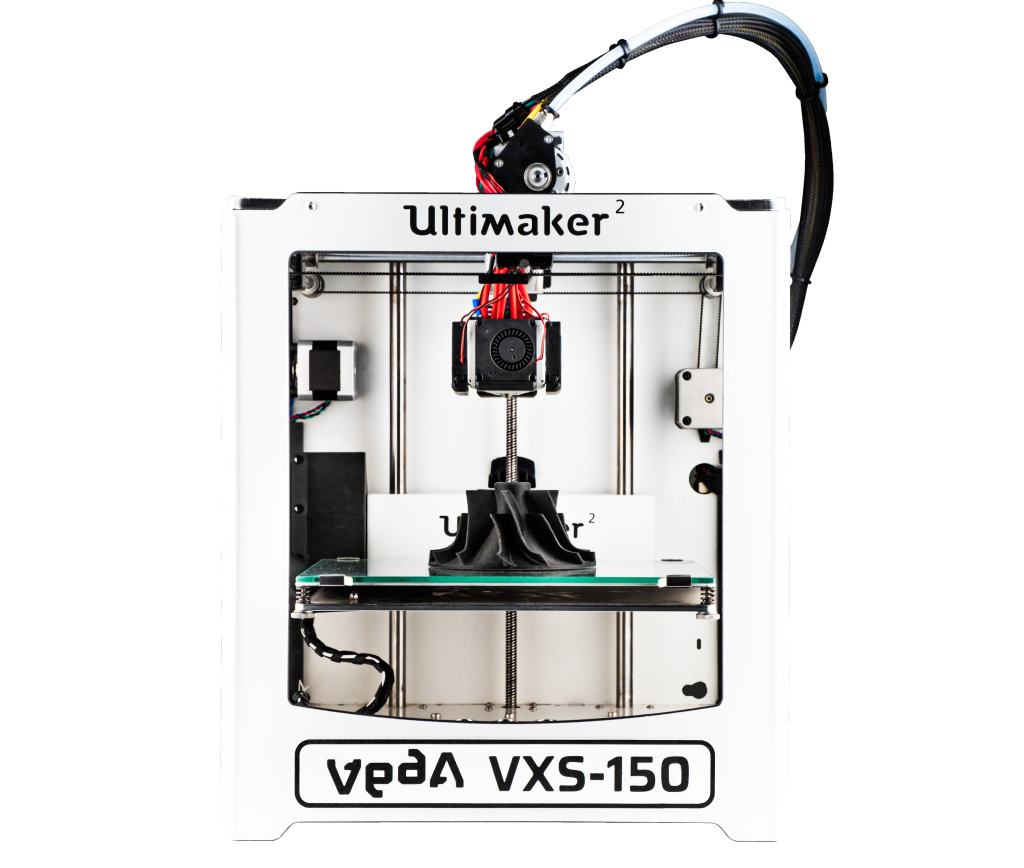

Designed to serve as an ‘all-in-one’ package for those seeking to boost their FFF 3D printing capabilities, the firm describes the VXS as a “no compromise, industrial powerhouse,” capable of processing 2.85mm filament at a pace of up to 150mm³/s, a maximum temperature of 450°C and a back-pressure of as much as 200N.

“Together, the VXS hotend and feeder produce one of the most reliable 3D printing platforms capable of leveraging FFF into applications such as small-scale production,” states the Veda 3D team. “The system is compatible with almost all 3D printers, and is particularly well-suited to larger, industrial machines using more advanced materials.”

Harder, better, faster, stronger FFF

Of course, the 3D printing industry is full of hardware developers working on new extruders, designed to enhance the capabilities of users’ machines. Earlier this year, for example, BIQU’s H2O and H2 500℃ extruders hit the market. The printheads’ high-temperature filament processing compatibility enable them to print engineering-grade materials such as PEI/Ultem and PEEK.

BIQU’s release closely followed the launch of FuseLab’s novel patented rotary extruder. Introduced alongside its first FFF metal 3D printer, the FL300M, the firm’s printhead is designed to increase the points of contact between materials and the nozzle’s drive system, as a means of minimizing print failures.

Going further back to mid-2020, Canadian OEM Dyze Design also launched a new Typhoon printhead for large-format 3D printers. At the time, the company said it had managed to achieve a flow rate of 200mm3/s using the extruder, but through switching to carbon fiber or any other type of filled material, it forecast that it could be possible to print 25% to 50% faster than with PLA.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Veda 3D’s Veda Extrusion System. Photo via Veda 3D.