Industrial cleaning system manufacturer Vacuum Processing Systems has demonstrated the efficacy of one of its existing finishing technologies for the post-processing of 3D printed parts.

Known as Vacuum Cycling Nucleation or ‘VCN,’ the process involves pumping liquids through components to remove any excess material from their internal cavities, inside a vacuum environment. Though the technology is more often used as a means of finishing traditionally-manufactured products, the firm is now marketing it as a method of post-processing complex printed parts as well.

Vacuum Processing Systems: a background

Based in Rhode Island, Vacuum Processing Systems is led by Dr. Donald Gray and Joe Schuttert, who have been designing and building cleaning systems since 1994. Between them, the enterprising duo hold 12 related patents, and using their mixture of academic and pharmaceutical expertise, they’ve managed to build a portfolio that addresses aerospace, medical and optical needs among others.

This offering is largely split between its Airless and Vacuum Vapor degreasers and VCN-based aqueous systems. While the former are designed to allow for the use of solvents to clean parts without them reacting to atmospheric conditions inside the chamber, the latter is more geared towards clearing out excess material from complex medical parts, or the piping often used within industrial settings.

Elsewhere, these technologies have previously found electronic applications, in the cleaning of flip chips, as well as the reprocessing of intricate surgical instruments. The firm has also increasingly publicized the potential of its systems within 3D printing, although it should be noted that it continues to market them to injection molding users too, thus it’s now expanding its reach rather than changing course.

“Additive manufacturing post-support material removal for SLA, DLP, CLIP or other photopolymerization printing methods still lacks the cleaning process equipment necessary to keep up,” says Vacuum Processing Systems via its website. “[While] present cleaning methods need to use low-temperature solvents like isopropyl alcohol, the VCN process is such a fast, thorough cleaning method, that higher temperatures can be used to decrease the cleaning time even further.”

What is VCN post-processing?

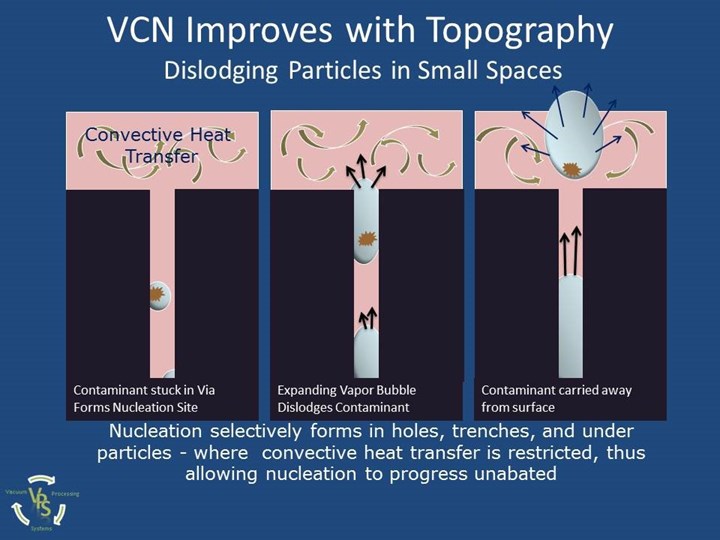

In essence, VCN involves placing parts into a chamber in which the air is removed, allowing the process to take place inside a vacuum. This chamber is then filled with either isopropyl alcohol or a soapy solution that, due to the system’s enclosed nature, begins to bubble at the part’s surface as its vapor pressure rises above the pressure of the compartment.

By activating and deactivating the vacuum in 1.5 to 2 second bursts, VCN-equipped systems are therefore able to pump liquids into components, before creating bubbles on-demand that pull excess material from tight spaces. Following a completed cycle, cleaned objects are later rinsed and dried while still inside a vacuum, as part of a process that’s said to take just 15 minutes from start-to-finish.

Although Vacuum Processing Systems continues to market VCN as an “exciting advancement in industrial cleaning,” the firm now offers it to those seeking a means of post-processing 3D printed parts too.

When used to finish plastic or metal 3D printed products, the process is said to be capable of removing uncured resin or unsintered powder in sub-30 minute cycles. What’s more, the technology’s high-temperature approach (that effectively ‘boils’ liquids into bubbling) enables it to rapidly clear out parts with even the most complex of geometries, something its creators say is critical to scaling production.

As a demonstration of VCN’s finishing capabilities, Vacuum Processing Systems has revealed that it was used to treat a double-cone produced for NASA by HAZMIN as part of the Green Products Program (pictured below). Even though the component featured just four tiny holes for powder removal, the company was able to clear its internal channels after a few cycles, showcasing its process’ efficacy.

Having been deployed to clean parts ranging from porous hip implants to hypodermic needles and heat exchangers, the company’s systems are now being marketed towards SLA, DLP, PBF and binder jet 3D printer users.

While Vacuum Processing Systems doesn’t price its systems upfront, those interested can request a quote via its dedicated website.

Ongoing advances in part finishing

As the number of end-use 3D printing applications continues to grow, post-processing technologies have had to advance in tandem, leading to all sorts of innovations in this area across the industry. XJet launched its new ‘SMART’ post-processing station in September last year, a system that uses intelligent algorithms to remove supports from ceramic parts, allowing users to automate the process.

Similarly, Additive Manufacturing Technologies (AMT) has partnered with Mitsubishi Electric to develop a fully-automated post-processing machine of its own. Composed of AMT’s PostPro3D chemical vapor smoothing system and Mitsubishi’s articulated arm bots, the set up is said to be the first of its kind to gain Underwriters Laboratories approval.

Earlier last year, DyeMansion also expanded its portfolio significantly with the launch of its new Powershot Performance series. Comprising the Powershot C, Powershot S and Powershot DUAL Performance systems, the firm’s updated lineup was said at the time to be built specifically for enabling high-volume shop floor 3D printing.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a NASA 3D printed test part prior to undergoing Vacuum Cycling Nucleation post-processing. Image via Vacuum Processing Systems.