A group of engineers at the University of Victoria (UVic) in Canada has received a $100,000 seed grant for the development of 3D printed back braces and orthoses. The medical devices are to be introduced as part of a non-profit initiative in low-income communities around the globe, helping treat children suffering from birth defects such as clubfoot and scoliosis.

A project with impact

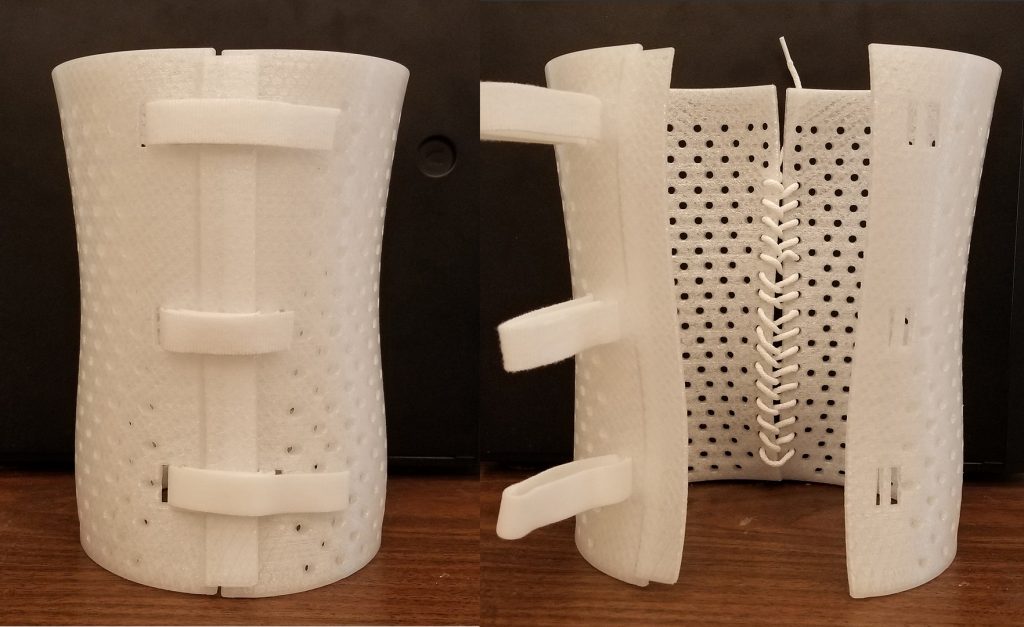

Left untreated at an early age, deformities in the feet and spine can cause permanent disability. Though relatively simple to treat, therapeutic care for such conditions typically runs into thousands of dollars, relying on traditional manufacturing and expert labour.

With the introduction of 3D printing, the cost of corrective devices, like back braces, can be cut dramatically. Production is also more mobile and, with proper training, can be controlled by anyone with a little computer know-how. This is the thinking behind UVic’s latest project, led by associate professor Nikolai Dechev.

Nepal and beyond

Seed funding has been granted to Professor Dechev’s team by Grand Challenges Canada, an agency aiming towards goals similar to those outlined by the Bill and Melinda Gates Foundation. According to the non-profit’s mission statement, “Grand Challenges Canada seeks bold ideas from the best and brightest innovators to save and improve lives in low- and middle-income countries.”

The UVic project will start introducing its low-cost medical solutions in Nepal and hopes to roll-out the system to other countries in the future. Inline with a sister initiative at the university, 3D printed spine and foot braces have the scope to reach at least 5 other countries where The Victoria Hand Project has already set up labs to make custom prosthesis.

In a comment to Western Canada’s Times Colonist, Professor Dechev states, “Eventually, it’s expected the Victoria Hand Project will inherit the orthotic technology and deploy it.”

Affirming a legacy

Guatemala was the first country to receive a Victoria Hand 3D printed prosthesis lab back in 2014, following a previous grant from Grand Challenges Canada. Three years later, the lab continues to provide prosthetic point-of-care to the community, and has provided the foundation for subsequent sites in Cambodia, Haiti, Nepal, Ecuador and Egypt.

This legacy is something Professor Dechev and his team will continue with its spine and foot supports. He explains, “[The technology is] not just thrown over the wall to people. There is a process of two to three years of follow-up to make sure everything is going well.”

Never miss a story: sign up to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Register now for our 3D printing industry jobs site.

Featured image shows Women and children under 5 in Mali – Photo courtesy of the Canadian Red Cross, via Grand Challenges Canada on Flickr