Researchers from the University of Toronto (UOT) have developed an open-source, low-cost 3D bioprinter for constructing complex vascular tissue structures.

With this custom bioprinter, the UOT researchers conducted a study seeking to resolve a concern within tissue engineering which derives from the poor development of vasculature – the arrangement of blood vessels in an organ or body part.

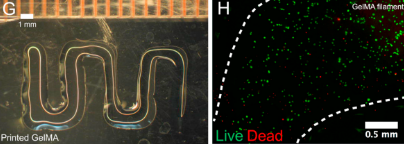

Using sacrificial materials such as gelatin and pluronic F-127 (PF127), a thermogel polymer, the research determined PF127 as the superior material for use in developing vascularized tissues. According to the research paper, this discovery “can potentially help accelerate the widespread adoption [of] 3D bioprinting to create such engineered tissues.”

This research contributes to the ambitious goal of many scientists working in regenerative medicine – which is to create functional 3D printed organs.

Branching vessel channels with bioprinting

Vascular channels are extremely important with the human anatomy as they encompass the system of blood vessels that supply blood through tissues to our organs, and ultimately our entire body.

These intricate channels are challenging to replicate using current tissue engineering methods, however, 3D bioprinting has enabled the creation of complex structures of varying lengths that can branch out and interconnect within a single construct.

Moreover, hydrogels, a polymeric biomaterial, have played an integral part in this research as their hydrophilic capabilities enable them to hold large amounts of water in a 3D networks. This permits cell growth and tissue organization, which leads to the formation of vascular channels.

This class of biomaterials has been used frequently within 3D bioprinting experimentation due to its structural similarity to a cell’s natural extracellular matrix (ECM).

Experimenting with gelatin and PF127

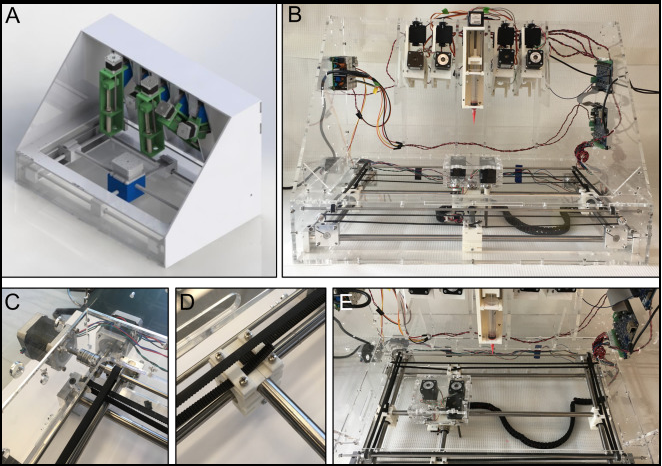

During this experiment, UOT researchers used their custom 3D bioprinter, which cost an estimated $3,000, to print the gelatin and PF127 materials within hydrogel constructs into a desired vascular pattern.

The modular 3D bioprinter included extruding systems 3D printed from ABS, to hold sterile 10 ml syringes. In addition, the printing system operated from an open-source Duet v0.6 controller board, which to managed five-axis motors (one in X, one in Y, and three in Z) and five independent extruders.

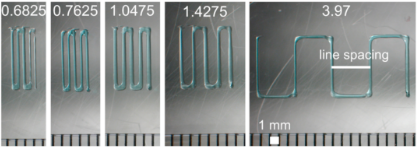

With a sufficient print resolution of 0.5–1 mm, the bioprinter successfully processed the sacrificial materials, maintaining a uniform filament diameter, to replicate complex vascular tissue structures. The materials were then compared based on its consistency and accuracy.

The study concludes, “We found Pluronic F-127 to produce filaments with higher spatial resolution, greater uniformity, and greater elastic modulus than gelatin filaments, and with low toxicity despite being a surfactant, making it particularly suitable for engineering smaller vascular conduits (channels).”

Stay abreast of the latest news in 3D printing by subscribing to the 3D Printing Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

On the lookout for new talent or seeking a career change? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows UOT custom bioprinter.