The University of Birmingham (UoB) has installed two of Renishaw’s RenAM 500M metal additive manufacturing systems to service its Centre for Custom Medical Devices (CMD).

The systems were installed by the UoB’s School of Materials and Metallurgy to accelerate the development of customized 3D printed medical devices. Dr. Sophie Cox, Lecturer at the University’s Healthcare Technologies Institute, UoB, said, “Additive manufacturing increases the design freedom for medical devices. Using the technology, we have flexibility in implant geometry and material choice,”

“The installation of the RenAM 500M systems will create a new center for custom medical devices at the University of Birmingham.”

A modern generation of medical devices

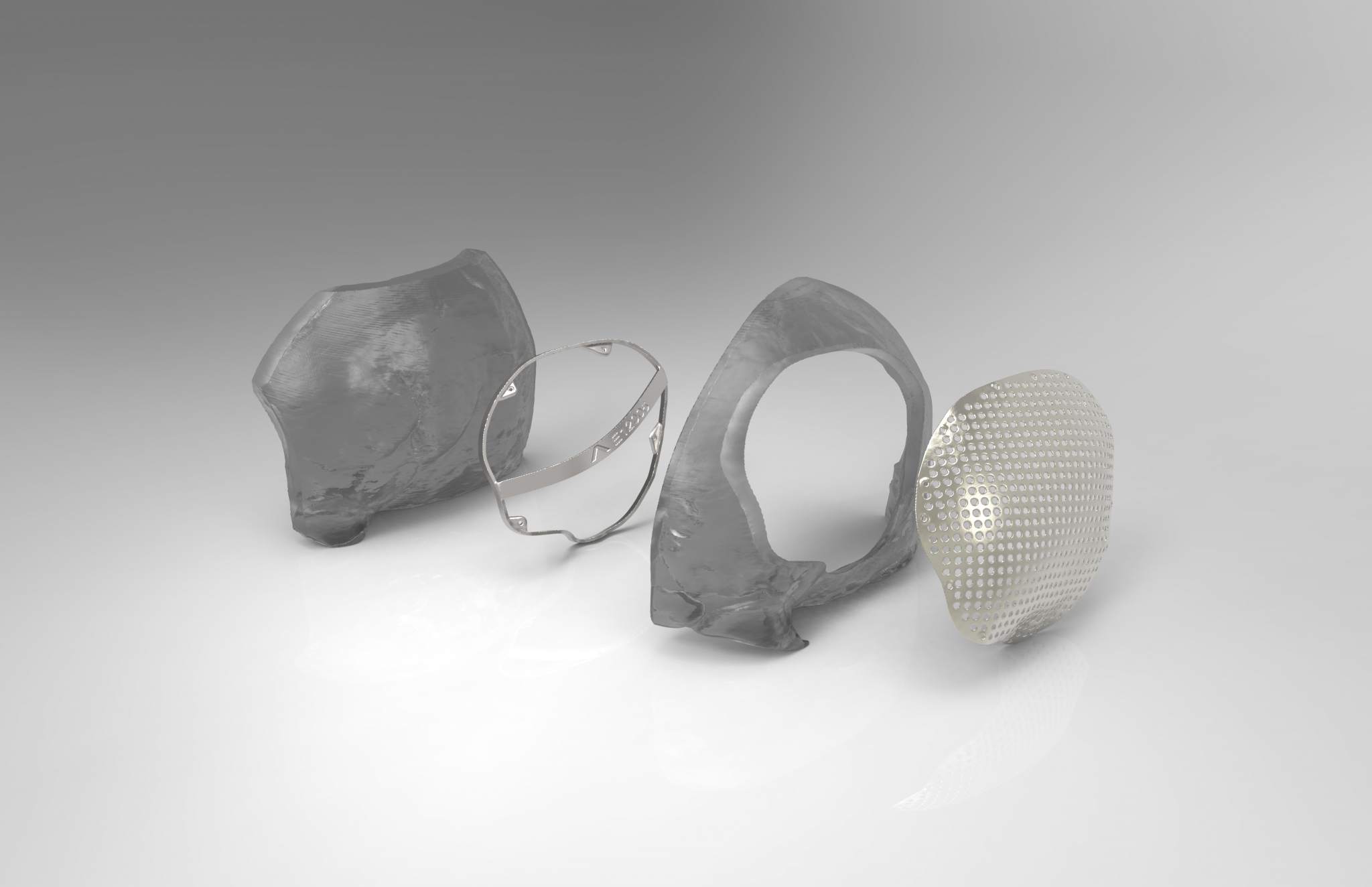

This recent project was established to embody academia, clinical and industrial practice and develop the ground for a healthcare partnership between the institutes. Its main objective is to connect academics from various disciplines to attain the full potential of additive manufacturing for medical devices. The current goal of the team is to enhance the available healthcare options with a modern generation of medical devices both therapeutically and anatomically tailored to the patient.

Dr. Cox added, “We chose Renishaw because of its experience as a custom medical device manufacturer, […] As a university, we are working towards ISO 13485 [medical grade quality certification] something Renishaw has already achieved,”

“This partnership is just the beginning of a pipeline of activities, where we will align our research capabilities with Renishaw’s know-how to realise the benefits of additive manufacturing for patients.”

Medical 3D printing at Renishaw

Earlier in 2018, Renishaw collaborated with Cardiff University Dental Hospital (CUDH) to develop 3D printed removable partial dentures using its DS20 optical scanner and AM250 metal 3D printer.

Prior to this, Renishaw and the Morriston Hospital in Wales helped save the life of a 71-year-old patient suffering from muscle cancer with a 3D printed titanium rib prosthesis.

One of the companies to benefit from the addition of Renishaw AM systems at UoB is Accentus Medical, a UK based company known to modify technologies with dedicated research and development of new technologies for the medical device industry. Accentus Medical will apply the technology to the surface of 3D printed cranial plates to lower the possibility of infections.

Bryan Austin, Director and General Manager of Medical and Dental Products at Renishaw, concludes, “This is a really enthusing project and we are excited about the future of the industry. Through its work with the Birmingham Health Partnership, the University has access to clinical input from local hospitals,”

“By collaborating with industrial, academic and clinical partners, it is possible to produce medical devices more quickly and at a lower cost, which will benefit patients receiving the implants.”

For more of the latest 3D printing news subscribe to our newsletter, follow us on Twitter, and like us on Facebook.

Searching for new talent or seeking a career change? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows Renishaw’s RenAM 500M at IMTS. Photo by Michael Petch.