An oral cancer patient at the University Hospital of Wales (UHW) has successfully received innovative post-cancer facial reconstruction, thanks to 3D modeling from the International Centre for Design and Research (PDR) and metal 3D printing from Renishaw.

Maxillofacial surgeon Mr. Cellan Thomas and restorative dental surgeon Mr. Liam Addy used 3D printed metal cutting guides to reconstruct the entire front and left sides of patient Bernard Thomas’ jaw bone, including space for dental implants.

A complex procedure

After cancer treatment destroyed a large section of Bernard Thomas’ jaw bone, an osteotomy and reconstruction was required. This complex procedure usually requires at least 10 surgeons in the operating theatre.

Traditional freehand surgery involving the manual implantation of fibula bone grafts would have been too inaccurate, while in-house prosthetics which need forming and welding were considered too great a risk for UHW.

As a result, Cellan Thomas and Liam Addy turned to 3D modeling to plan the surgery precisely. They also used additive manufacturing to build metal cutting/drilling guides and implants in single pieces with specific geometries.

Modeling to plan the surgery and design the cutting guides

The PDR, based at Cardiff Metropolitan University, is a design consultancy and applied design research center that the surgeons chose for modeling services.

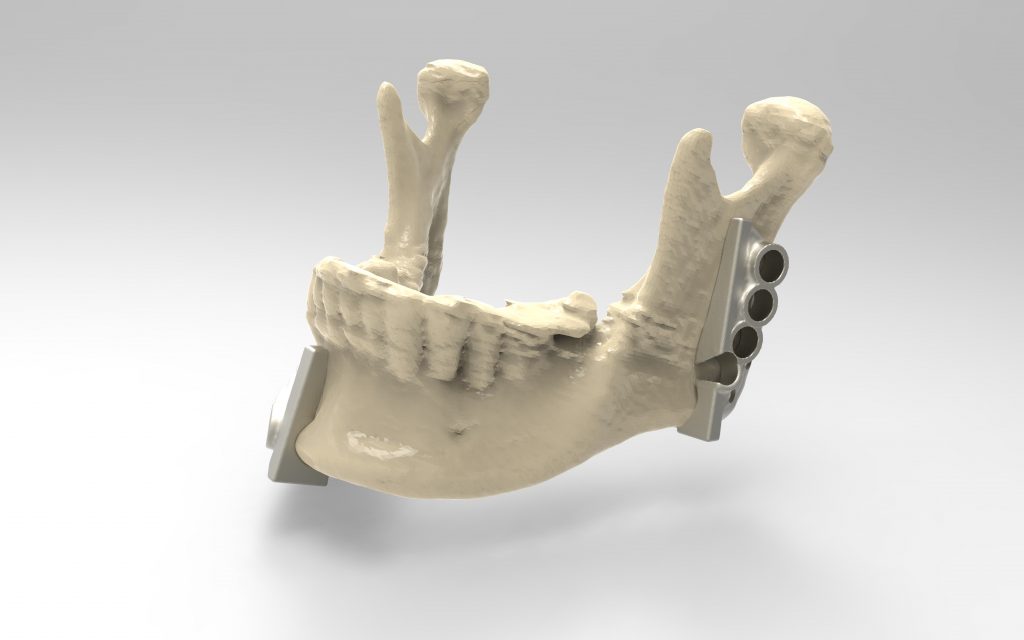

To manufacture the 3D models, PDR converted CT scan data from UHW to .stl files, before creating a 3D model in Freeform Plus software of the jaw and fibula.

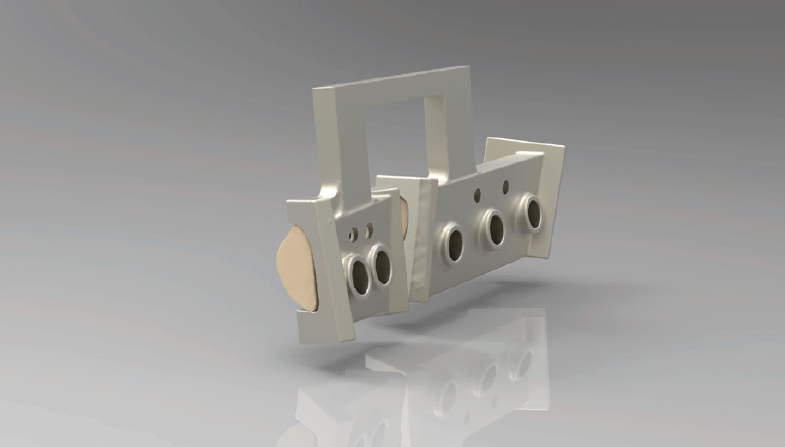

PDR designed a cutting guide for the fibula according to the surgeons’ requirements to precisely harvest two sections of healthy bone and vascular connective tissue. This ensured that the new section of the jaw would have a healthy blood supply. The designs also incorporated pilot holes for precise final fixations screws.

Cutting guides were then designed for the jaw itself, with flat surfaces showing where to excise cut bone with a saw, and guide holes showing where to pre-drill. Screw keys for the drill holes had a triangular aperture to allow liquid to keep bone cool during drilling.

Finally, a mandibular plate implant was designed with two “push and click” features to ensured that bones and connective tissue had been correctly positioned.

3D printing the cutting guides and models

PDR 3D printed the surgical models on which the surgeons could prepare and practice their procedures.

The .stl files for the cutting guides and the mandibular plate were sent to Renishaw, which manufactured the components on the Renishaw AM250 metal 3D printer using titanium alloy Ti MG1.

The precise contours of the bone surface were captured on the cutting guides, improving the precision of the cut, and ensuring that the two bone pieces were cut at precisely the correct angles to build a strong joint and aid the osseointegration with as few gaps as possible.

The procedure faced no complications, and the patient recovered, enabling restorative dental surgery with implants and bridges after the bone had knitted together.

Ed Littlewood, Marketing Manager at Renishaw’s Medical Dental Products Division said:

“This is a great example of taking the best practices of precision engineering into hospital applications to deliver better, more predictable outcomes which benefit the patient, the hospital team and have overall cost savings.”

Let us know what you thought the best medical application of 3D printing was this year. Make your nominations for the 3D Printing Industry Awards 2018 now.

For more stories on 3D printing and surgery, subscribe to our free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Featured image shows the fully reconstructed mandible with a plate and dental implants inserted. Image via Renishaw.