3D printer manufacturer Ultimaker and materials specialist LEHVOSS Group have jointly received a first-of-its-kind printing process certification from global testing firm TÜV SÜD.

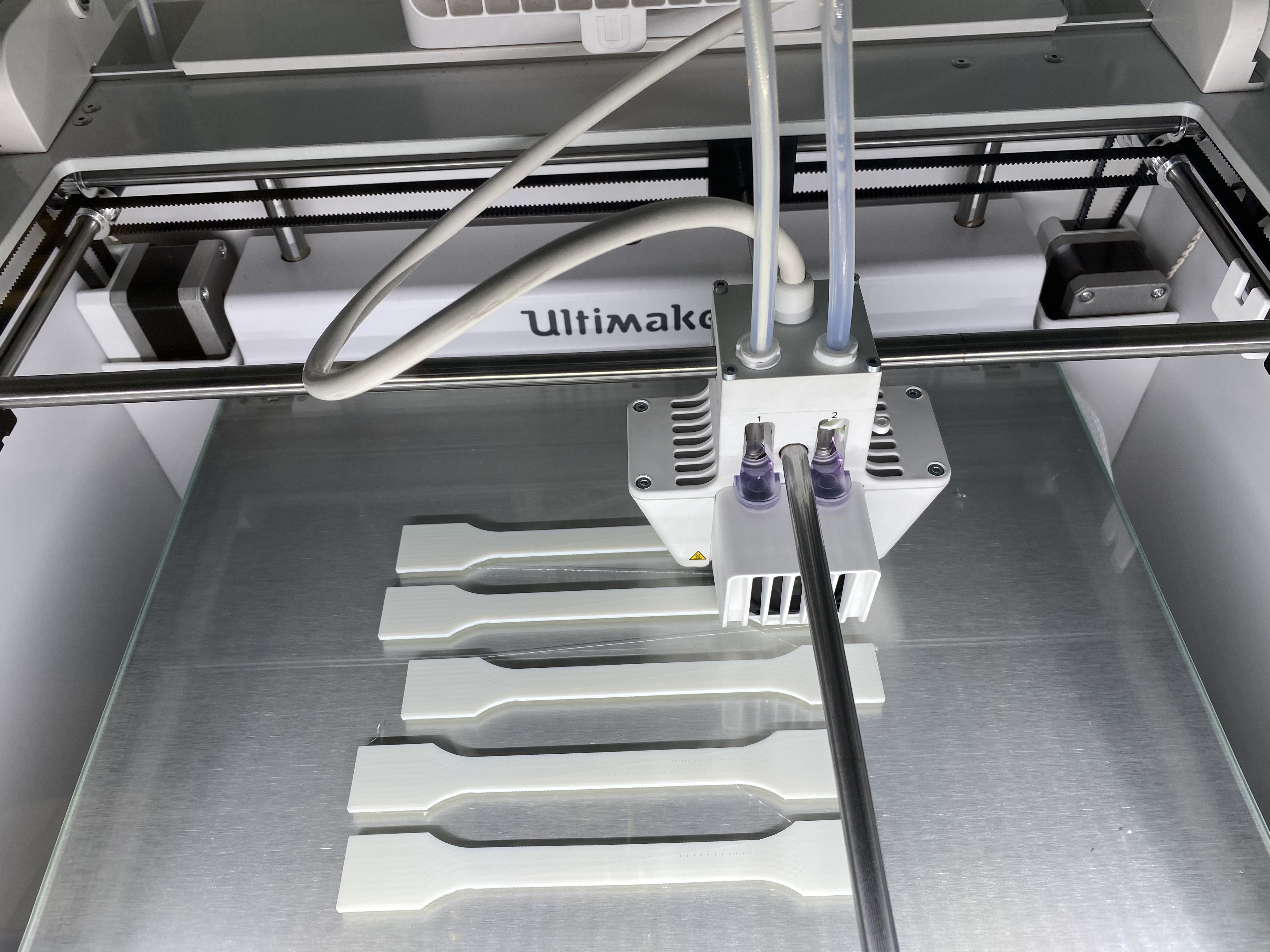

The certification, voluntarily commissioned by the two partners, specifically covers the 3D printing process of LEHVOSS’ LUVOCOM 3F filaments on Ultimaker’s S5 Pro Bundle, which features the S5 FDM system. Included in the certificate is the reproducibility of the material properties and test specimens, which comprises dimensional tolerances, filament production, the pressure process, and even the level of harmful emissions during extrusion.

Jos Burger, CEO at Ultimaker, states: “We are thrilled to receive this certification from TÜV SÜD and look forward to our continued collaboration with the LEHVOSS Group. This certification proves that parts produced with the Ultimaker S5 Pro Bundle and LUVOCOM 3F are done in an accurate and reproducible way. By many of our customers this is considered very important and often even a prerequisite for the implementation of FFF 3D printing with engineering materials in advanced applications.”

A reproducible build process

The TÜV SÜD certification was granted after a multi-step testing process, which initially involved an on-site inspection of both manufacturers’ facilities, ensuring high quality and traceable production processes. Then, a quality audit of the S5 Pro Bundle, 3F filaments, and printed test specimens was conducted. To top things off, TÜV SÜD performed its own mechanical properties tests, VOC and ultrafine particle testing, and geometric precision testing at its own facilities.

According to Gregor Reischle, Head of Additive Manufacturing at TÜV SÜD, this project marked a world first. The testing process was the first ever instance of a certification institution such as TÜV SÜD testing for a ‘reproducible additive manufacturing build process’ as part of a certification program, with Ultimaker and LEHVOSS essentially acting as a pilot case. The testing method was invented to alleviate the high costs typically associated with build process validation, which Reischle considers a “pain point” in the 3D printing industry.

Reischle adds: “The test basis, with the underlying standards, helps all market participants to see the difference between 3D printing for prototyping and 3D printing for production purposes. The certified reproducible printing process helps users in particular to reduce technology integration costs. Minimizing integration costs for production purposes creates more willingness to integrate and trust. We hope that it will benefit many applications and industries for cost-transparent, safe and high-quality implementation.”

The S5 Pro Bundle and LUVOCOM 3F series

Ultimaker’s S5 Pro Bundle has three separate components to it: the S5 FDM system; an Air Manager designed to catch and trap up to 95% of the ultrafine particles emitted by the machine; and a Material Station for housing filament spools in a humidity-controlled environment. Complementing it, the LUVOCOM 3F filament series comprises four different materials, two of which are carbon-fiber reinforced. They are based on either PA or PET, and are specially formulated for high-performance applications. The partners now hope that their newly granted certificate will enable customers to rely on the S5/3F combination with trust.

To ensure 3D printed COVID-19 devices adhere to the strict quality requirements and legal regulations medical devices are subject to, TÜV SÜD recently drafted several checklists for 3D printing processes and provided them to manufacturers throughout the pandemic. Beneficial for testing laboratories, healthcare specialists, and the public, the lists have been supplied free of charge since September.

Earlier this year, the certification firm also held the 2nd TÜV SÜD Additive Manufacturing Conference in Munich. The event brought together high-level 3D printing experts to hear industry leaders and academics share their thoughts on the implementation of industrial additive manufacturing with standardization and digitization.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the S5 Pro Bundle. Photo via Ultimaker.