In the latest study from the University of Alberta’s Ingenuity Lab, hydrogen fuel cells take on a utterly unexpected form. 3D printed in the shape of a maple leaf, the cells expand in water and split molecules of H2O. Though a novel demonstration, the leaves show how 4D printing can be used to make objects with a biological function. A precursory image of bio-engineered, transplantable and artificial organs.

A “deviation from the mainstream”

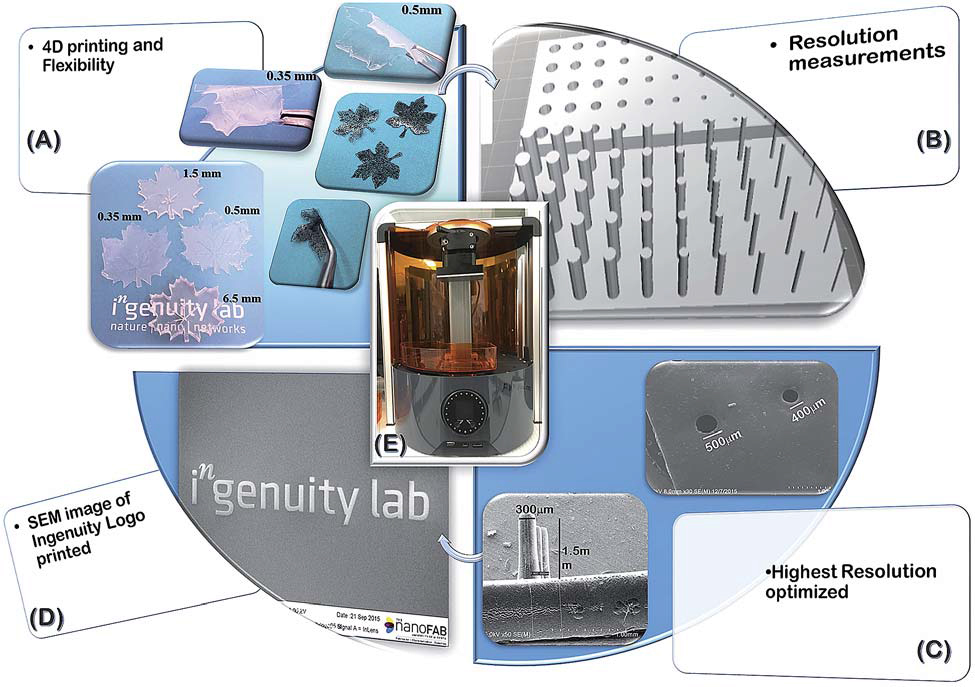

Biological maple leaves at the Ingenuity Lab are made from a bioink containing silver nanoparticles, carbon nanotubes and membrane proteins. The chosen method of fabrication for the leaves, using SLA, is defined by the researchers as “a deviation from the mainstream 4D printing.” As such, the self-activating behaviour of the material is not motivated by shape memory or cell proliferation, but instead by the need for a chemical function, as occurs in nature.

Stella Mathews, lead researcher on the UAlberta study, explains the reaction that takes place as follows: “When you irradiate the protein inside with UV, it generates a proton, which reacts with the silver nanoparticles to split water and generate hydrogen.”

The process could also be used to generate other molecules essential to the healing of living tissue.

The first of many still to come

In the future, such a bio ink would ideally be used together with a mechanical material to make an improved variety of medical implants. “We would print it with a material that has the mechanical properties that can withstand the pressure of the bones,” explains Stella Mathews, lead researcher on the UAlberta study, “…as well as have some factors that can promote cell adhesion.”

Giving artificial knee cartilage as an example, Mathews says that the ink would prevent the meniscus from rejection by the immune system, she hastens to add, “But this is only phase one of many.”

The full article discussing Bio nano ink for 4D printing membrane proteins is available online in the journal RSC Advances. It is co-authored by Anu Stella Mathews, Sinoj Abraham, Surjith Kumar Kumaran, Jiaxin Fan and Carlo Montemagno.

Never miss out an another story – subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Nominations for the second annual 3D Printing Industry Awards are now open. Make your selections for best research team and more here.

Featured image shows UAlberta’s Stella Mathews holding up a 3D printed maple leaf sample. Photo by Michael Brown