Researchers in Germany are using 3D printing to improve treatments for babies with cleft lips and palates.

In a study conducted at the Technical University of Munich (TUM), scientists have used 3D printing and semi-automated workflow to improve the process of nasoalveolar molding (NAM), a medical procedure used to help children with birth defects that affect their upper mouth/lip.

In a report by the World Health Organization (WHO), published in 2015, cleft lip and palate rates in Europe have not changed significantly since 1998, though the average rate for Germany continues to be 10.59-22.94 per 10,000 births. That same report also mentions that the United States has seen a rise in children affected by the conditions, going from 10.3 to 12.37 cases per 10,000 births.

Efficiency with 3D printing

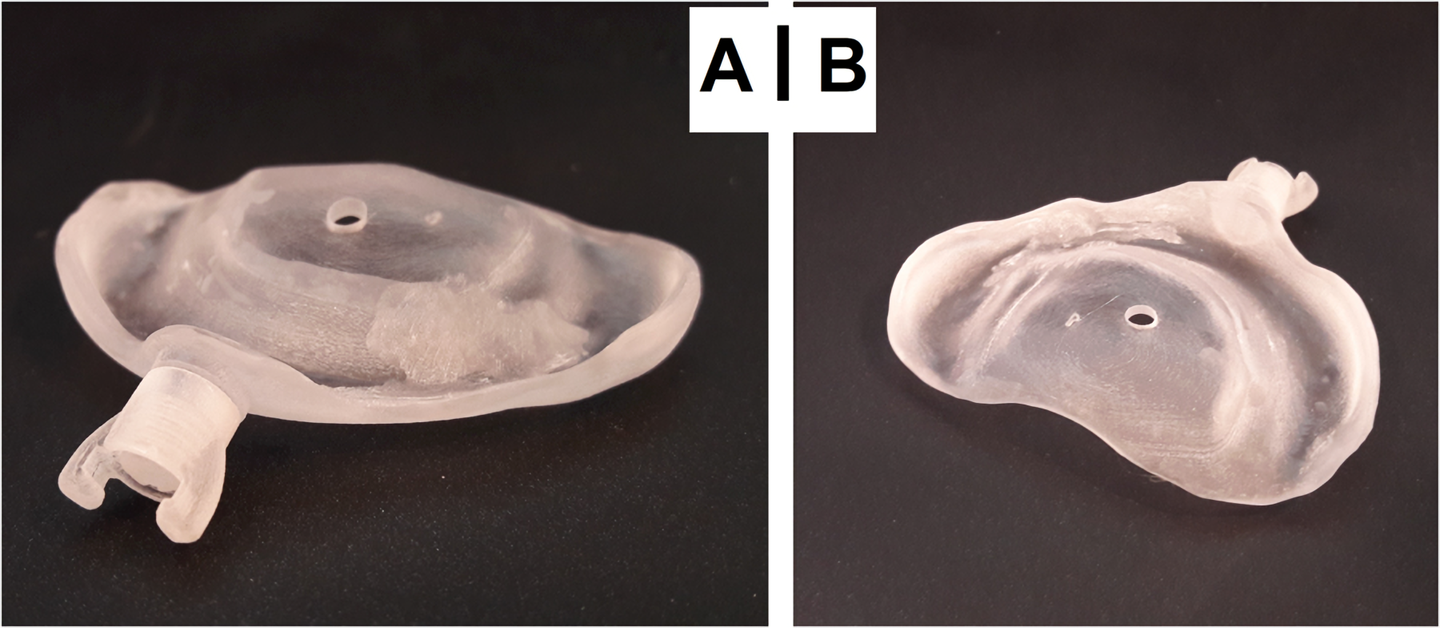

A typical NAM procedure uses a plastic plate to reform an infant’s lips, gums, or nose before undergoing surgery. While this allows for fewer, more effective surgeries, the technique requires constant new plates to be developed as the child grows. This leads to lengthy treatments found only in specialized locations.

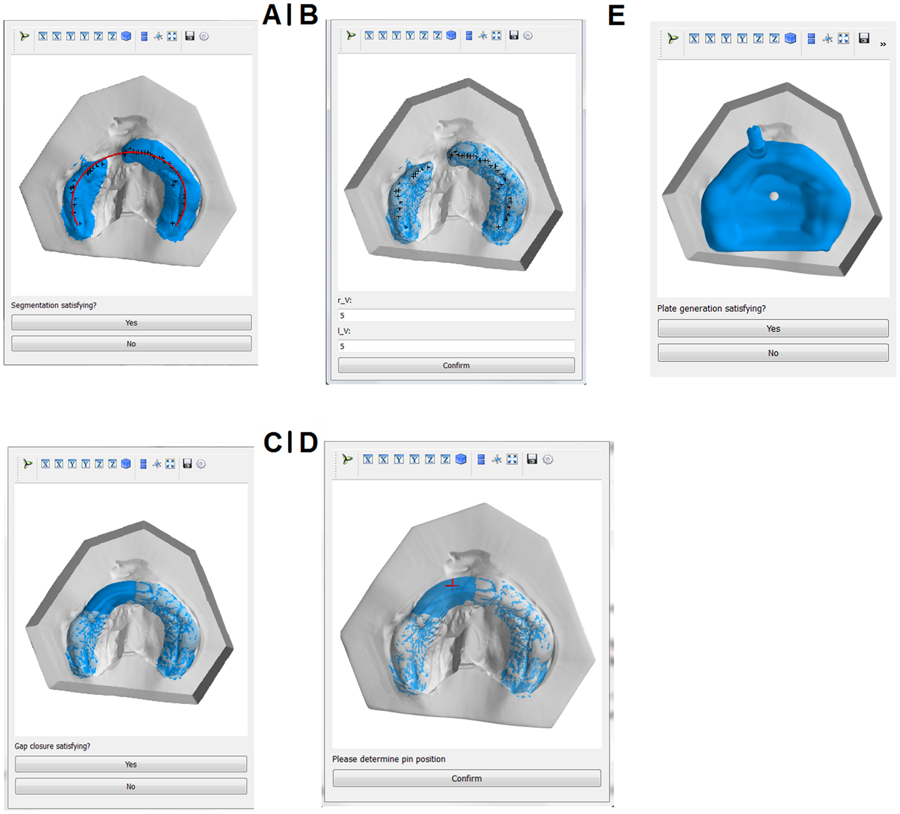

The new TUM process, known as RapidNAM uses a semi-automated approach with automated detection of the alveolar ridge (upper and lower jaw ridges). This automatic detection means that NAM plate-molds are made faster and more effective than the traditional method where the ridge was given space for expansion. The molds are then digitized with a 3Shape brand 3D triangulation scanner.

Because the TUM process automatically detects the alveolar ridge, a graphical user interface (GUI) was created for any necessary edits.

TUM’s process is faster than the standard technique which required more manual design. Additionally, the use of 3D printing technology can produce molding plates at a faster, cheaper rate than the traditional method.

According to the TUM report, “RapidNAM overcomes previous limitations of conventional CAD/CAM-intraoral molding plates by its semi-automated workflow. The GUI creates a series of molding plates within a few minutes but still allows changes by the user. The resulting plates are as adaptable as conventional NAM-devices.”

3D printing and facial reconstruction

This isn’t the first time 3D printing has been used to help solves issues with cleft lips and palates. In 2015, Michigan doctors accurately managed to predict an unborn child’s cleft lip by translating MRI scan data into a 3D printed model. With this they were able to determine if the cleft lip would pose a danger to the child’s breathing.

Similarly, in 2017, doctors at Ninth People’s Hospital in Shanghai used 3D printing to reconstruct the face of a woman deformed due to a rare septic infection. The doctors used 3D printed models to guide the construction of the newly formed nose and mouth.

The TUM report concludes, “RapidNAM gives good clinical results and may bring nasoalveolar molding to a broader practice.”

“A semi-automated virtual workflow solution for the design and production of intraoral molding plates using additive manufacturing: the first clinical results of a pilot-study” is published open access in Scientific Reports journal. It is co-authored by Florian D. Grill, Lucas M. Ritschl, Franz X. Bauer, Andrea Rau, Dominik Gau, Maximilian Roth, Markus Eblenkamp, Klaus-Dietrich Wolff and Denys J. Loeffelbein.

Want to stay up to date on 3D printing news? Then sign up to our 3D Printing Industry newsletter. You can also follow us on Twitter, and like us on Facebook.

Seeking new professional opportunities? Search and post 3D Printing Jobs now.

Featured image is a 3D scanned model of the mouth. Image via Technical University of Munich.