3D Printing Industry is taking an in depth look at how additive manufacturing is moving to production. Over the coming weeks the results of interviews with industry leading practitioners will be published.

This article is part of a series examining Trends in Additive Manufacturing for End-Use Production.

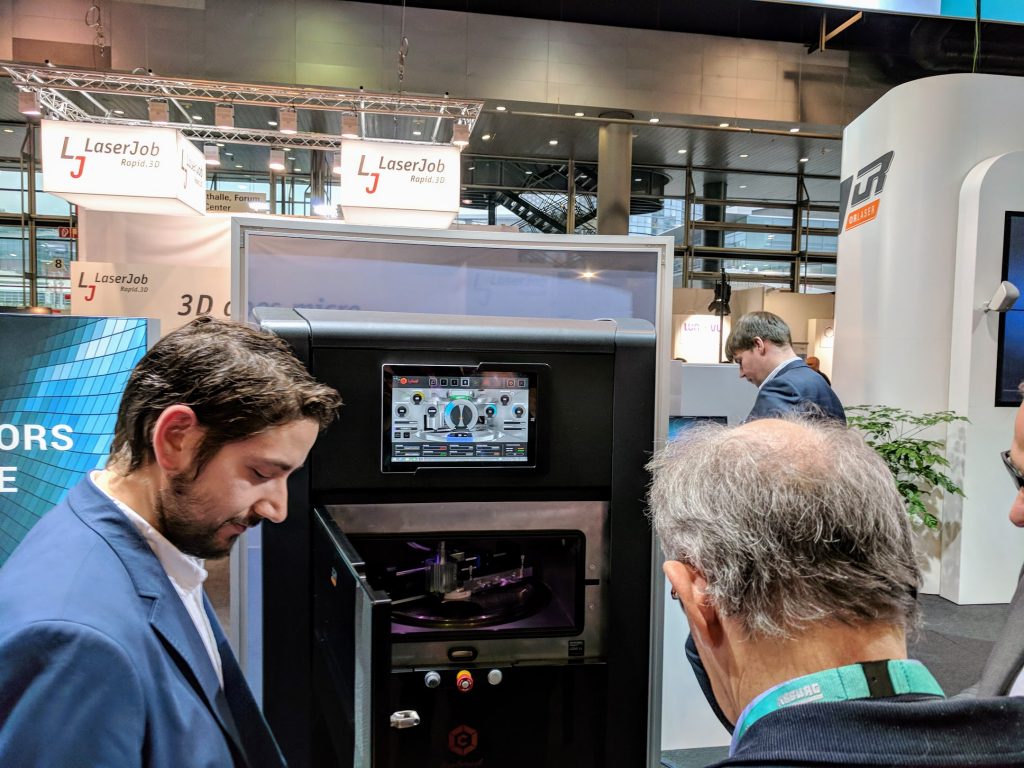

Eric Herrmann is the Online-Marketing-Manager at O.R. Lasertechnologie GmbH. With the ORLAS CREATOR, an innovative powder-bed based 3D metal printer, OR Laser are lowering the barriers to entry for additive manufacturing.

3D Printing Industry: What is your percentage estimate of how much your printers are used for production versus other applications?

Eric Herrmann: The most of our printers will be used for medical applications. My estimation is that over 60-70% of all CREATORS are used for production of medical products. 10%-20% for production of other products and 10-20% for research and development.

3DPI: Which industries are leading in the use of AM for production?

EH: At the moment for big printing devices (building platforms > 250mmx250mm) automotive and aerospace. For small systems (100mm and smaller) dental applications and jewelry.

3DPI: What barriers does AM face for production and how are these surmountable?

EH: The main problem currently is to enable a full automatic production process. From generating of the printing files to removing the support structures after the printing job. Furthermore the quality issue is an important point and a technical challenge. To implement quality control technologies such active process monitoring and closed loop process control will help to increased process stability and quality. These are also very important future development focal points for OR LASER.

3DPI: Are there any notable trends in AM for end use production?

EH: Lot of companies are working on the complete industrial 4.0 autonomous factories. But until today no one has a really satisfying solution to the technical challenges. Through this approach, the systems are getting bigger, more complex and extremely expensive.

OR LASER tries to use a different approach. We believe the key is to make the system more cheaper and more easy to use. To reduce the complexity of the technology to a level, small and midsize companies can benefit, will open the technology to complete new areas in end use production. The main trend in the market currently is that every 3D printing company is trying to develop their own 3D printing software to get more independent from companies like materialize. This helps to develop a printing software that is easy to use but powerful enough to satisfy the requirement of the end user and reduce the final price for the customers. A trend, where we could already set important accents with our CAM Software ORLAS SUITE.

Nominations for the 2018 3D Printing Industry Awards are now open. Let us know who is leading the industry.

For more information about the ORLAS CREATOR is available here.

This article is part of a series examining Trends in Additive Manufacturing for End-Use Production.

If you found this insight useful, then subscribe to our newsletter and follow us on social media.