The USA, Patents and Progress

‘The first step in winning the future is encouraging American innovation. None of us can predict with certainty what the next big industry will be or where the new jobs will come from. Thirty years ago we couldn’t know that something called the Internet would lead to an economic revolution. What we can do—what [The United States of] America does better than anyone else—is spark the creativity and imagination of our people. We’re the nation that put cars in driveways and computers in offices; the nation of Edison and the Wright brothers; of Google and Facebook. In America, innovation doesn’t just change our lives. It’s how we make our living…’ – U.S. President Obama, State Of The Union Address, 2011

3D Printing and the Third Industrial Revolution

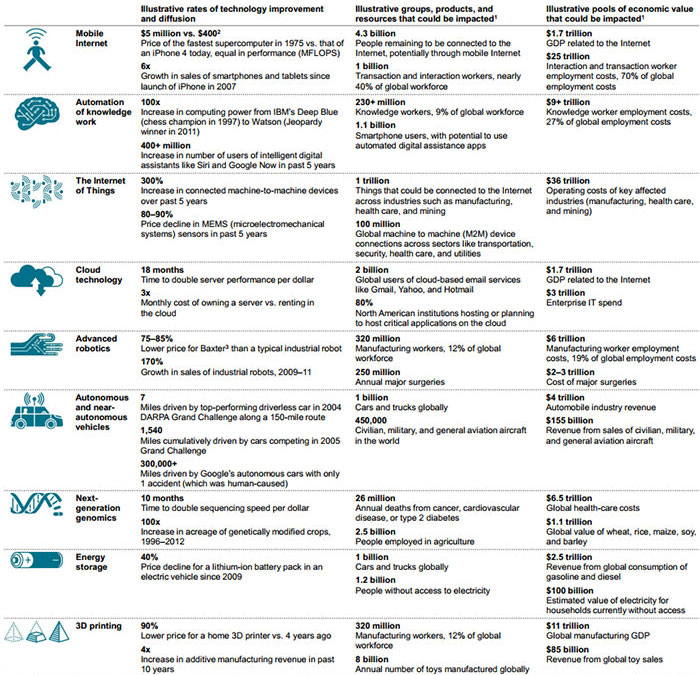

To quote a recent IBM study, the trends that emerged from previous era’s of rapid acceleration of new technology, such as the First Industrial revolution, and the Second Industrial Revolution (also known as the Technological Revolution), the Guilded Age in the U.S.A. and the intertwined Digital Revolution and the Information Revolution (or Internet Revolution), are about to undergo a disruptive transformational shift in paradigm, and 3D printing is one of the key technologies at the root of this:

‘The historical rules hardened by a century of experience are being overturned by three emerging technologies: 3D printing, intelligent robotics and open source electronics. Together, they are creating a manufacturing environment that can be defined and executed through managing software and data files – a transformation we describe as moving from a hardware-based supply chain to one that is “software-defined.

To understand how the competitive landscape of the Electronics industry will change and how these technologies will impact real-world, financially driven enterprise investment decisions, we conducted the 2013 IBM Electronics Manufacturing Study. The study is comprised of two primary research components: a face-to-face survey of 55 executives in 10 countries and a quantitative model to measure the effects of ongoing industry changes.

These newer technologies can produce an average 23 percent unit cost benefit and reduce barriers to enter manufacturing by an astounding 90 percent. Yet half of our survey sample has no manufacturing strategy to manage the impact of digitization.

By changing requirements for scale, location and volume, the software-defined supply chain won’t just changes costs or manufacturing processes – it will effectively up-end the industry structure as we know it.’ – The new software-defined supply chain, IBM 2013

I gave a brief retrospective overview into the nature of the previous industrial ‘Revolutions’ and how they impacted the era’s in which they occurred both technologically and sociologically in my lead in to how Ion Core and the Zinter Pro 3D printer are representing the UK in the Third Industrial Olympiad. Rather than repeat those words verbatim here, I would urge readers to use the link above to read the first two sections of that article to garner a context for the technological transformative shift that we are currently residing in — the Third Industrial Revolution, which I touched on there and intend to expand upon here:

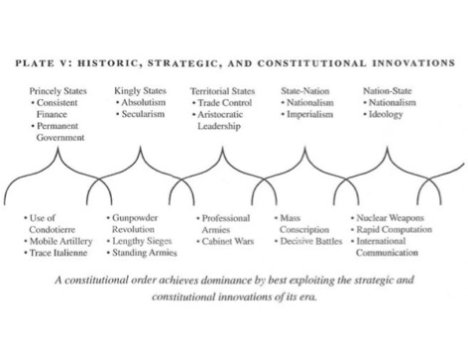

World War Two produced the Nuclear Age, with it’s double-edged sword of the tempestuous shadow of Mutually Assured Destruction, and radiant light of nuclear energy: The latter remains highly controversial within the context of the Long Island incident and the tragedies at Chernobyl and, most recently, Fukushima.

Another world changing phenomena that war produced is an era of ever-more rapidly accelerating progress in computational processing machines via the efforts to crack the Enigma Code that have resulted in processing power sufficient for a range of devices as broad as the four function calculator to the space shuttle. Cheap processing power in 2014 has progressed more than many could have believed possible — today’s smart-phones holds more processing power than the early space shuttles.

Also international communication, which first broadened into a range of distinct extant technological devices, and now with the Third Industrial Revolution, has become embodied in the form of the Internet, smart devices (smart phones, tablets and smart TV’s), and, over the next three decades, all devices via the Internet of Things – ‘The Web Of Everything.’

The Third Industrial Revolution: Why Is It Happening Now?

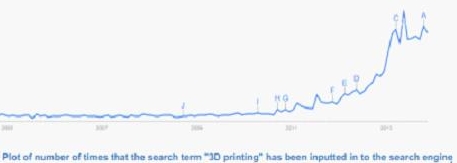

3D printing has been called — or featured as a leading technology in — the Third Industrial Revolution. The premise of the promise of additive manufacturing has been projected to disrupt traditional industry in a way not seen for nearly a century. Predictive methodologies are infinitely more advanced than the early years of the First or Second Revolutions, so, currently, an eerie exultant hype, aura of expectant excitement and an era of anticipation surround the potential of 3D printing. In the midst of this phenomena, the eye of the storm resides calmly over a number of level headed innovators in a number of start-up companies, who are gathering the ingredients for the 3D devices that will be at the fore of this nascent market.

There are a plethora of individually faceted variables that constitute a solid answer to why 3D printing is a primary emergent technology in 2014. As with all systems and trends, extracting one individual or even a thousand grouped variables will never provide more than an illustrative sketch of causality.

These range from deep philosophical and linguistic reasons: such as the nature of language elements being subjective to interpretation based upon a readers culture, knowledge and cognitive capacity to Aristotelian segmenting of areas of thought requiring a counter-reductionist macroscopic holism that mankind has only just begun to approach via Big Data, Quantum Computing and the Web Of Everything, to the innate inherent problem that any system measured by mankind is altered by the process of measuring it. This is of relatively little importance to minor systems and measurement, but of ever increasing importance for larger samples of intertwined systems and, thus, the more that Homo Sapiens Sapiens has a causal affectual interrelationship with those systems.

However, those variables include:

• Improvements in computer processing power

• Increases in computer storage capacity

• Exponential growth in digital network infrastructures

• Increases in low cost energy concentration technologies

• The growth of open source as a recognised IP strategy

• Decreases in the cost of electronics

• Increases in availability of alternative funding strategies such as crowd-funding

• Greater research in material sciences

• Advances in 2D printing technologies.

These and more variable factors have facilitated the catalysation of innovation in the 3D printing sector. Comparisons have been made between the current stage of development of nascent home 3D printers with the early days of the Personal Computer (PC), which was the key technology that facilitated the digital revolution, compounded by the inception and explosive growth of the internet, then other key factors such as smart devices and social networks: home desktop 3D printers could be considered as ‘Personal Producers’ (PP), or ‘Personal Manufacturers,’ providing a fairly analogous democratisation of production unto the democratisation of computation and information that is the socio-economic legacy of the PC.

3D printing is oft cited as being a disruptive technology, akin to the personal computer. One simple way of assimilating this description is that the technology that changes many processes changes many businesses and lifestyle choices. It may be worth remembering however even a technological phenomena as monolithic as the Internet has limitations in its reach and socio-demographic impact.

Whilst the sociological and psycho-emotive trend of tech-fear that held a large proportion of the population back from personal computation devices has diminished with the advent of more user-friendly interfaces such as the touch-screen smart-phone, still a large minority of the over 50’s demographic in neo-industrialised (my term for the return of manufacturing to post-industrial societies) societies have no desire to consciously involve themselves with personal computation devices. There is a level of illusion in this lifestyle choice however, as the microchip finds its way into an ever greater number of household devices: microwave ovens, ovens, refrigerators, TV’s, digital disk (CD, DVD, Blu-ray, etc.) players and so on.

The onus here is that disruptive technologies affect life-styles indirectly more than directly. Thus, whilst a majority of households may never have a 3D printer*, they will be affected indirectly by the growth of use of additive manufacturing methods that supplement subtractive and moulding manufacturing methods in industry. This induces greater personalisation, in time diminishing costs as more energy efficient methods of additive production occur, particularly in combination additive / subtractive machines. They will also be affected by the decreased costs induced by the displacement of logistics as the need for shipping is reduced.

The whole economy will, in this authors current opinion, become more disparate: a revitalisation across extraction and processing of raw materials as the Materials Genome Project and similar efforts produce a far wider range of materials, manufacturing will experience the largest disruptive shift from 3D printing, new digital service arenas will evolve in new ways, as, in time, the developments of the primary economic sector filter through inevitably to processing and then sales related activity, traditional services will decrease, as the conglomeration of retail into supermarkets continues, with a brief counter-resurgence of traditional means of sales and service before a slow but inevitable decline. The Quaternary Sector – related to intellectual activity, will experience some direct and feedback benefits from 3D printing, in broad and perhaps unpredictable ways given the nature of empiricism. From medical research to military strategy, laboratory equipment to space faring research, many intellectual disciplines will be affected by the paradigm shifts in the primary to tertiary sectors: at it’s most direct causality particularly in tandem with the Internet of Things and Big Data.

The nature of the increase in manufacturing and disruption of services is of course difficult to fully predict, yet increasingly probabilistically viable as industrial additive manufacturing draws outsourcing of production back to the home nations of companies and large corporations begin to use currently experimental new models such as the Amazon model of the delivery drone.

The near future of the retail SME (Small and Medium Enterprise) seems secure. Between 2020 – 2030 however, delivery drones, the personal robotics revolution then home 3D printing will create new ways of living. This lifestyle change will occur in a number of ways. The primary macroscopic variable will be an increase in the means of the household to expend energy in work – in both the physics and physiological sense – thus ‘produce at home’ rather than pure purchase by direct retail. We currently purchase the majority of items rather than create them primarily because it saves time for the households individuals to concentrate upon their specialisations: their job role, their field of study, etc.

As energy and materials become cheaper now that innovative and even exological (my own term: ‘beyond the Earth’s atmosphere’ – within this context: near orbital solar energy, asteroid capture, etc.) means of acquisition develop; GDP growth will be liberated beyond the extent of the Earth’s resources.

Population growth will plateau – around 9.1 billion according to the projections of leading research bodies – until the potential of the democratisation of space-faring may emerge in the second half of the 21st century. There are already open-source crowd-funded space-faring projects, but the widespread use of this model will be restricted politically because of security concerns. Once those security concerns are resolved via military technology, such as an electro-magnetic surveillance tracking field via Earth bound, geo-orbital and lunar assets, the democratisation of space-faring within the Earth-Luna may become legal. It will be the USA, plus the EU, China and India that will be at the fore of this paradigm.

Thus the means for mankind to acquire energy and materials will increase (slowly at first and at significant R&D expense) whilst population growth initially levels off. Looking back at Part One of this Trends Series, the wheel of humankind, growth catalysts for the economy, uptake rates for new technology and earth systems, the resultant exposition is that GDP per PPP will continue to unilaterally increase. Economics within any capitalist system means that this will continue to drive down costs for most products and services, although it is the increase in energy and materials scarcity that will put strain upon human and Earth systems before we witness this. Sustainability is thus the crux.

With projects already beginning to address FFF home 3D printing waste recycling such as the Ethical Filament Foundation, Filabot, Filamaker, Om Nom Project and the use of the biodegradable material Polylactic Acid (PLA) iterated as a primary material from the inception of the FFF patent liberation by the RepRap project, a systems process trend is notable for potential imposition and improvement upon other materials as they are invented for home 3D printing. Even home 3D printing in 2014 can thus be materials efficient regarding sustainability and, to an extent, energy expenditure.

All-in-all this means cheaper personal robotics, cheaper industrial and home 3D printing, and what with the cross-over of the two, and cross-over for delivery drones, ultimately the potential for cheaper, more materials-efficient logistics. Thus, in turn, the potential end of some – if not eventually many – sectors of retail on the high street.

This is, if the projected trends and more emerge as promised, no less than the Third Industrial Revolution.

In the nearer term, the McKinsey Quarterly January edition “3D Printing Takes Shape,” sums up the disruptive trends for business succinctly, trends which will have their greatest affect upon the leading ‘neo-industrial ‘Market-States such as the United States Of America:

‘1. Accelerated Product-Development Cycles: “Over time, 3-D printing will begin to affect how companies think about R&D more broadly, given how the technology enhances the ability to crowdsource ideas through remote cooperation. For some companies, that crowdsourced brainpower might one day begin supplanting R&D activities, making its management a new priority.”

2. New Manufacturing Strategies and Footprints: “As costs continue to fall and the capabilities of 3-D printers increase, the range of parts that can be economically manufactured using additive techniques will broaden dramatically.”

3. Shifting Sources of Profit: “Reducing the reliance on hard tooling (which facilitates the manufacture of thousands of identical items) creates an opportunity to offer customized or bespoke designs at lower cost—and to a far broader range of customers.”

4. New Capabilities: “While there is a wealth of knowledge around design for manufacturing, much less is available on design for printing. Our conversations with executives at manufacturing companies suggest that many are aware of this gap and scrambling to catalog their design know-how.”

5. Disruptive Competitors: “New businesses are already popping up to offer highly customized or collaboratively designed products. Others act as platforms for the manufacture and distribution of products designed and sold online by their customers. These businesses are gaining insights into consumer tastes and building relationships that established companies could struggle to match.”

I believe that many reports currently underestimate the mid-to-long term economic affect of additive manufacturing methodologies, contingent upon whether the current and near future wave of FDM / FFF desktop 3D printers produce localised leading brands that are successfully marketed to create awareness; logistically easily available via local retail outlets as well as online stores; realistically affordable; finger-burn and room air quality accident-safe; and most of all technologically accessible by fulfilling the plug-and-play ideal. I call them the 5 A’s: awareness, availability, affordability, accident-safe and accessibility.

Supply logistics look reasonably likely to be heavily disrupted over that time-frame by delivery drones and home 3D printers. As we witness home 3D printers become ever more able to fulfill the 5 A’s, as well as the technological progression factors of multi-material capacity, increased resolution, larger build area and particularly print speed, end users will become increasingly tempted by the chance to download products to 3D print at home over traditional consumption logistics.

There are now many media stories in prose of the origins of 3D printing, so let us view the progress of the generic set of technologies formerly most referred to as additive manufacturing and now mostly referred to as 3D printing via patents awarded. It is patents within a capitalist economic modality, particularly the free-market strain of this highly efficient system. There are pertinent points to note however that differentiate the recent early growth of the home prosumer desktop 3D printer from many other products.

It is an open source patent that produced this trend. Let us move on to the vital pending debate upon modes of Intellectual Property that 3D printing is predicted to produce: not just via the much cited potential of individual means of production to displace tens, or hundreds, of billions of dollars worth of copyrighted intellectual property, but the host of additive manufacturing technologies themselves. The term ‘3D printing’ can be deceptive relative to the wider reference of this means of manufacturing, as additive manufacturing the means of making by adding materials together is iterated in hundreds of distinct individual methods, and broader sub-terms which distinguish particular methods from each other.

3D Printing Patents and Progress

‘Valuing intangibles has been consistently a problem for most industries, even more so for an industry like 3D printing. Patents could become a potential key for dominating the market once a technical victor arises out of the arena.’ – Seeking Alpha, February, 2014

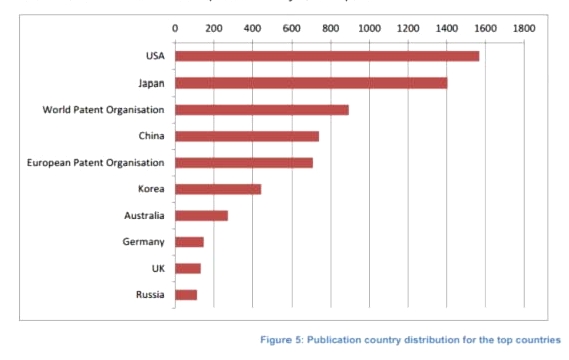

Given the industrious technological leadership of the United States in the 20th century, we should anticipate little surprise in finding that there is a lead in additive manufacturing patents registered in the USA. Japan, with its history of technological innovation, comes a close second, especially close when comparing the GDP of the two States, but also understandable given the Japanese economic onus upon high-technology. China in third place for a State has but half of the patents registered in the U.S., a reflection of the more recent emergence of China as an academic as well as industrial superpower.

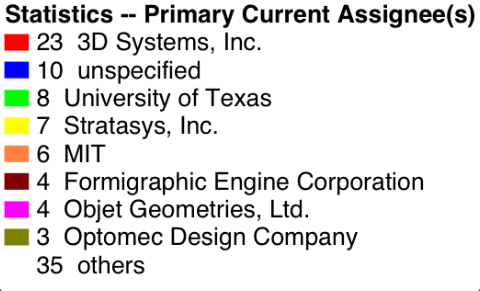

Within the US. The following numbers of patents specific to additive manufacturing show a huge lead for 3D Systems, in part because of its recent acquisition strategy, in part because of innovation. Here follows a list of assignees for US-based companies:

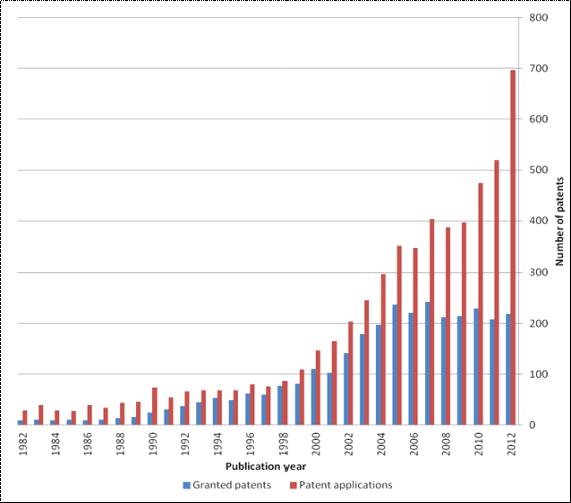

The patenting systems used by most of the pre-industrial world originated in Italy, in the industrial era in the UK and in the post-industrial era in the US. Now, we reside in what I would term the ‘neo-industrial’ era, where post-industrial economies seek to catalyse native manufacturing rather than outsourcing to developing economies – in part the legacy of the Rise Of The East. The following trend graph illustrates the numbers of distinct, extant additive manufacturing (3D printing) processes patented over the past three decades.

Particularly of interest is the increasing dichotomy between applications and validations:

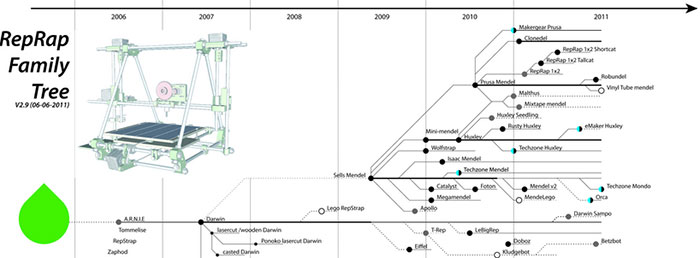

The current wave of home prosumer desktop 3D printers can generally be traced to the RepRap Project of self-replicating machines: 3D printers that can print most of their parts – and more now that home 3D metal printers have arrived – to create a new 3D printer. This project uses a strategy that is the very antithesis of standard modern patenting, embodied in the constitutional right to property of the US. The initiator of the project sought and succeeded in creating an open source ecosystem, which has produced a plethora of printers — hundreds of distinct devices now exist.

In his short 2004 overview Adrian Bowyer called it ‘Wealth Without Money‘ and the said professor broke the concept down to just three bullet points and a subsequent paragraph:

‘The three most important aspects of such a self-copying rapid-prototyping machine are that:

1. The number of them in existence and the wealth they produce can grow exponentially,

2. The machine becomes subject to evolution by artificial selection, and

3. The machine creates wealth with a minimal need for industrial manufacturing.

‘…This could turn rapid prototyping from a development into a production technology. It also means that people of modest means will be able to own them, and also let their friends have copies. They will be able to make themselves a new flute, a new digital camera, or just a new comb by downloading the designs for them from the Web. Some of the designs will be sold; some will be available free.’ – Adrian Bowyer: ‘Wealth Without Money, 2004.

The example of the ‘liberated’ Fused Deposition Modeling patent owned by Stratasys, which Professor Adrian Bowyer reiterated as open source in the RepRap Project is the foundation of most of the current wave of amateur, prosumer and increasingly also larger business-orientated 3D printers.

With a 2014-initiated 20-year IP protection now covering a period equivalent to the 100 years before it via the exponential rate of increase of rate of change of technology, new ways of catalysing innovation, profit and economic growth are pertinent.

To quote an insightful and perhaps inciteful insight from an article featured on Seeking Alpha from February this year: ‘The two behemoths in the industry, Stratasys (SSYS) and 3D Systems (DDD) both have sizeable patent portfolios. Partially as a result of software patent wars, many believe that this industry will devolve into the same pissing contest. Their comparisons usually focus on recent patent infringements between Samsung (OTC:SSNLF), Apple (AAPL), and Google (GOOG), but this perspective ranges from wrong to absurd.’

USA-Based Industrial Additive Manufacturing (3D Printing) Players

‘America Makes is the National Additive Manufacturing Innovation Institute. As the national accelerator for additive manufacturing (AM) and 3D printing (3DP), America Makes is the nation’s leading and collaborative partner in AM and 3DP technology research, discovery, creation, and innovation. Structured as a public-private partnership with member organizations from industry, academia, government, non-government agencies, and workforce and economic development resources, we are working together to innovate and accelerate AM and 3DP to increase our nation’s global manufacturing competitiveness.

Based in Youngstown, Ohio, America Makes is built upon an extensive network of additive manufacturing technical expertise from across the nation to advance additive manufacturing and create new jobs. America Makes was founded in August 2012 as the flagship institute for other National Network for Manufacturing Innovation (NNMI) institutes across the country and is driven by the National Center for Defense Manufacturing and Machining (NCDMM).‘ – America Makes

America Makes is a part of the U.S. National Manufacturing Initiative, a strategic project that aims to renew manufacturing as a key core sector in the world’s current largest single economy: An economy that already lies slightly behind the European Union and is forecast to be surpassed by the Peoples Republic of China this decade. Revitalising manufacturing in the USA has arguably never been so critical for the world’s most powerful Nation State.

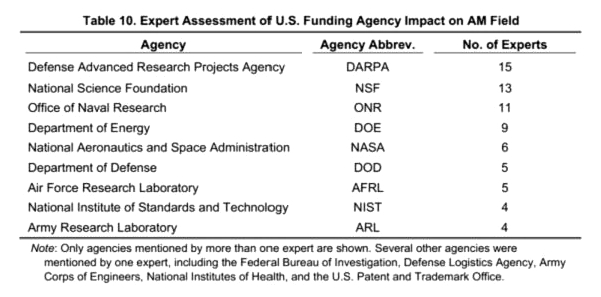

The US government’s synergistic investments in additive manufacturing include: NASA; the US Air Force; US Department of Energy (DOE); National Institute of Standards and Technology (NIST); and National Science Foundation (NSF), catalysed by America Makes (formerly the National Additive Manufacturing Innovation Institute), which is a public-private partnership created to drive 3D printing into mainstream US manufacturing.

Share Performance

Above is an illustration of the leading players in the production of industrial additive manufacturing machines. There are two clear leaders, corporations that have pursued an aggressive strategy of acquisitions over the past 24 months. Also we have witnessed rapid growth for ExOne and voxeljet since their Initial Public Offerings. Organovo is the first publically floated player in the bioprinting sector, which has received a massive amount of publicity, given the company’s primary products: 3D printed human organs such as skin and a whole liver.

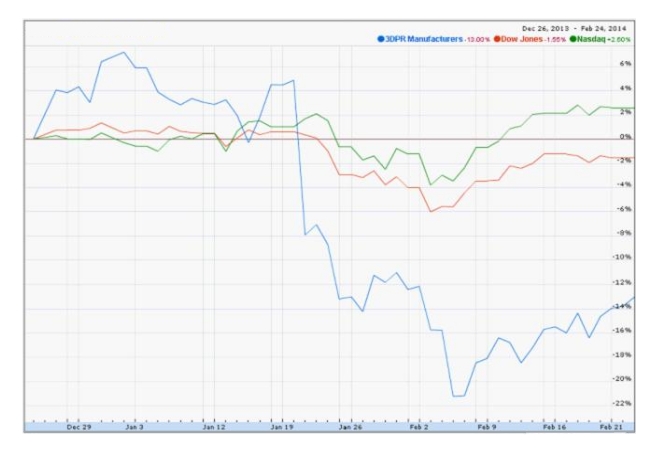

There has been a vast amount of hype and counter-hype regarding 3D printing stocks. The reader of this series of Trends articles will already have learned insights into the nature of human systems, world systems, technological progress, the increase in rate of change of technology, the increase in uptake of consumer electronics, projected potential for 3D printing and its place amidst the top new technologies by economic impact such as the Internet of Things and Big Data. I hope to have already countered a number of the world’s analysts’ negativity regarding 3D printing and various stirrings of uneasiness with the potential of the technology. The sector’s drop in Jan-Feb 2014 was partly a result of the constant talk of over-hype.

Mass media hype caused an inflation of valuation for 2013, but that very investment is merely an additional catalyst to progress and dividends in 2014–2018, the period that the sector will prove itself. If you keep the shares you have, they are at the very least more likely than not to give profit returns, and this author believes large returns for those who do not waver in the face of negativity from less informed sources. Many, perhaps even most, analysts do not appreciate a number of the aforementioned factors already discussed in Part 1 and Part 2 of this series. Many seeming self-justifications have appeared over the past 24 months in investment circles regarding the causes of The Great Recession. Investor confidence is varied, consumer confidence is low. The macroscopic variables represent the context for the psychology of the market.

A good spread of established and rising stars in the 3D printing sector, along with a wider spread with long term established return givers in other sectors as most risk evading mid-to-long term portfolios should contain, is a good bet. As with any form of gambling, a good bet is never a sure bet — but this writer believes that so long as the two key players hold course with their current strategies, they are good indicators of things to come. For one key technological and economic variable, 3D printing is analogous to App Platforms such as those held by Apple, Google, Microsoft and Facebook — a wide range of applications across a wide range of sectors, with the potential to disrupt many of them.

I will be going into much greater depth on all of the trends and variables discussed here for my own analyst service in the near future, whilst continuing to give free insights here at your favourite 3D printing news source.

*I believe that they will, though the guise of which will not resemble the current modes of FDM and SL 3D printers that we bare witness to in 2014: for future projections of a subject narrative and quantitive extrapolatory nature, see the final part of this series on trends in 3D printing.