As Twitter user, @matt_avo, put it: “what’s this patent bullshit?”

On August 20, 2013, Chris Norman, CEO of Kraftwurx, was granted the patent for an online customizable 3D printing service causing some to wonder how this might affect existing websites that offer such services. But, before there was MixeeLabs, Zazzy, even i.materialise or Shapeways, there was Kraftwurx. Only, back then, it was called Digital Factory. The story behind Kraftwurx is rife with personal drama and possible (but probably no) corporate intrigue that all began in 2004.

As the Kraftwurx blog tells it: Fascinated with the emergence of online services like NikeiD that allowed for the online customization of consumer goods, Chris Norman, a manufacturing engineer, spoke with a friend about pursuing a similar route in regards to rapid prototyping. In the span of two years, between 2004 and 2006, Norman wrote up the patent, raised capital, and set-up a demo for “the world’s first Mass Customization portal for 3D printed products”, what he would call Digital Factory (operated under his company, Digital Reality). Unfortunately, Norman’s “wife’s mother fell ill with cancer and with a growing family, Digital Reality was pushed aside but not forgotten.” He continued operating what became a digital advertising firm under the name Digital Reality when, in 2008, Norman discovered that there were others out there with similar ideas of customizable 3D-printing services:

I received a phone call from Carl Dekker, President and CEO of Met-L-Flo, a successful RP bureau in Chicago. He was calling me to announce that someone had beaten me to market, a company that we won’t mention by name but we are sure you will know who they are…I was devastated at first but it quickly turned to jubilation because my business model had been proven…better still, they did not get everything correct, leaving me with opportunity to learn from their mistakes and solidify our position.

According to SolidSmack, the CEO originally thought that Shapeways may have gotten the idea from Norman himself, saying in a mysterious e-mail:

I believe that Shapeways came from Makers Fair 1 year after I disclosed my idea (see attached). Jeremy Toeman and Adam Berg were in California and involved with Makers Fair and Shapeways showed up the next year. They got the web portion pretty much correct but not the system.

As Norman points out, however, the idea behind Digital Factory, and Kraftwurx, has more to it than a simple online repository for customizable designs. What they are proposing is a network of 3D printer suppliers from a single consumer interface. So, not only can you customize an object online – choosing from over 60 materials – and have it printed, but you can have it printed as locally as possible. Kraftwurx taps into its network of suppliers (125 at last count, according to Norman), finds the closest one to you, and has your object printed. Then, you have the opportunity to rate the object, a feature that Shapeways has yet to offer. More than that, you can connect with designers via the Kraftwurx site to have projects completed at your request. In that way, Kraftwurx hopes to be a “factory-in-a-box”, a one-stop-shop for your design development, production and sales needs.

The first patent for Norman’s “Made to Order Digital Manufacturing Enterprise” was granted “Allowance” in 2012. And, on August 20, 2013, his patent, which sounds so much like other online customization services for 3D-printed objects, was approved:

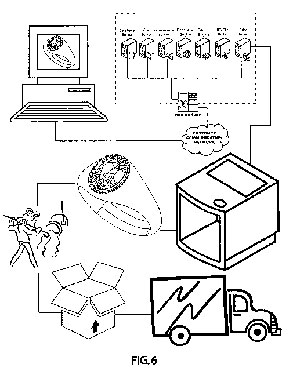

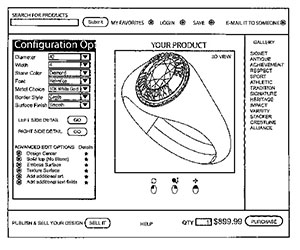

The patent, a long one, is filled with diagrams and descriptions of a cloud-based service bureau that allows users to tweak 3D models and then have them printed locally and sent to their homes. With Chris Norman owning the patent to a technology that other companies are now using, it’s difficult to say what, if anything, will happen to Shapeways and the like. Because I’m not a patent lawyer, I will use the opinion of Scott Dunham, of Photizo Group, to describe the effect that this patent might have on the market:

So there you have it! We don’t know exactly what this means, but it must mean something, right?