Voting closes today in the 3D Printing Industry Awards 2023. Have your say now!

3D printing company Tectonic-3D has launched a series of new 3D printing materials at Formnext 2023.

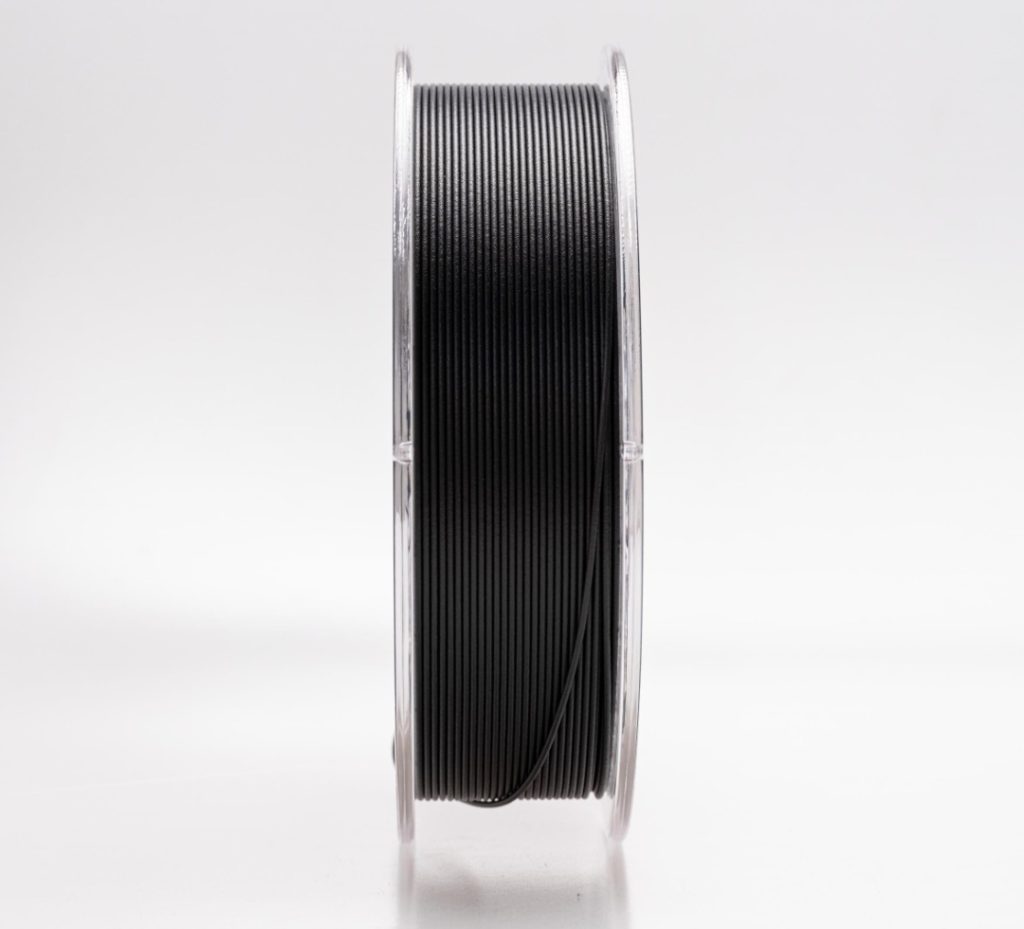

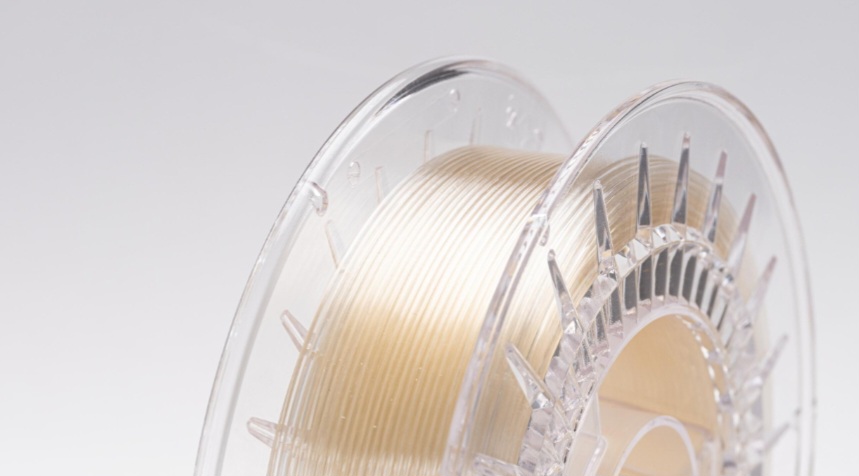

These materials, named TenneT KRATIR PA11 CF, TenneT PROTEOS HT, and TenneT PYRA PC/ABS FR, signify the company’s venture into the development of high-performance filaments. Patrick Duis, CTO at Tectonic-3D said, “We are proud to present our first series of filaments and new website, which embody our dedication to deliver consistent quality and performance to our customers.”

High-performance filament choices for industrial 3D printing

TenneT KRATIR PA11 CF, a Polyamide 11 filament infused with Carbon fiber, boasts a 98% biobased composition. Tailored for industrial and engineering applications, it strongly emphasizes strength and durability, coupled with superior heat resistance and minimal moisture absorption. In the context of high-temperature, soluble support materials, TenneT PROTEOS HT takes center stage, says the company. Demonstrating thermal stability of up to 215°C in build chambers, it caters to ultra-polymers such as PEI, PI, PPSU, and PEEK.

Safety and reliability are key considerations with TenneT PYRA PC/ABS FR, as it complies with flame-retardant and electrical regulations. This material finds its niche in applications where enhanced thermal performance and fire safety are paramount, especially in electrical components and enclosures. Simultaneously, Tectonic-3D has undertaken a redesign of its website and webshop. The revamped platform is strategically crafted to enhance the overall customer experience, offering seamless access to the company’s 3D printing materials and resources. Beyond a product showcase, the website functions as a central hub for industry news and innovations.

Enhancing capabilities and applications with materials

Multi-material 3D printer developer Inkbit introduced TEPU 50A elastomer, a thiol-ene polyurethane-based material with Shore 50A durometer, at this year’s Formnext tradeshow. Catering to complex components, it boasts low compression set, UV stability, and chemical compatibility. Positioned as a versatile mid-range hardness elastomer, TEPU 50A stands out for its surface finish and elasticity, suitable for detailed geometries. Engineered to surpass traditional molded silicones and rubbers, it offers an advanced solution for the automotive and industrial sectors, addressing limitations in 3D printed elastomers and showcasing the potential of additive manufacturing.

Netherlands-based 3D printing resin manufacturer Liqcreate added the Liqcreate Flame Retardant HDT material to its resin offerings. This engineering 3D printing resin, holding a UL94 V0 flammability rating, features high-temperature resistance suitable for applications in engineering, mobility, consumer goods, and electronics. Known for rigidity and compatibility with various resin-based 3D printers, it works with DLP, LCD, and laser-based systems. Notably, it withstands high temperatures, making it ideal for tooling, connector housings, and covers. The resin’s UL94 V0 rating and exceptional HDT-B value of 257°C position it for applications in automotive, aircraft, trains, and electronics, meeting stringent industry standards.

San Francisco-based manufacturing bureau Fictiv unveiled a suite of 14 new materials tailored for demanding industrial additive manufacturing projects. Among the diverse range are high-temperature selections like Ultem 9085, biocompatible alternatives such as ABS-M30i, and optical SOMOS materials. These materials find application across a spectrum of sectors, including automotive, industrial, consumer products, and medical fields, facilitating the creation of functional assemblies, jigs, fixtures, and large-scale production. Notable additions, such as Nylon 11 fire-retardant and soluble tooling material ST-130, offer advanced properties suitable for intricate and challenging applications.

Read all the 3D Printing Industry coverage from Formnext 2023.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Tectonic-3D’s company logo. Photo via Tectonic-3D.