3D Printing materials company taulman3D is today introducing six new filament materials via Kickstarter. The new ToolBox of six new materials has already been fully developed and tested in line with the company’s stellar reputation in this area and to reduce risks for backers.

I wondered about the move to KS, particularly considering taulman’s previous success with new materials. It turns out that while the company works hard to push the boundaries with new filament properties — in line with client and industry requirements — there are barriers to developments when dealing with the necessary chemical companies. Taulman explains that: “the minimum purchase requirements are significant for specialized polymers. With 1, 2 and in some cases 3 ton minimum buys, our ability to bring these great new materials to the community would otherwise take about three years. Because these materials were developed specifically for 3D Printing with the direct help of the chemical companies, they require specific production runs. Most chemical companies can produce small runs within their R&D labs of 50-250 lbs. But we will need to buy tons and to do so is a significant investment.” By utilizing Kickstarter, taulman says backers’ support will provide a “foot in the door” to the chemical companies.

And it is the chemical companies that taulman believes “are the real guys …. not the guys who want to toss in a handful of nano-this or graphene-that into a warm puddle of plastic, but Companies with real answers that will help everyone take 3D printing to the next level.”

Since 2011 taulman has been developing high strength materials for makers and for industrial users of 3D printing tech with notable success with the Nylon 618 and 645 materials as well as the tglase transparent material. This new range of materials extends the portfolio considerably and are bundled in a materials “ToolBox” to provide everyone with a selection of specifications and capabilities to meet their specific needs. The ToolBox comprises:

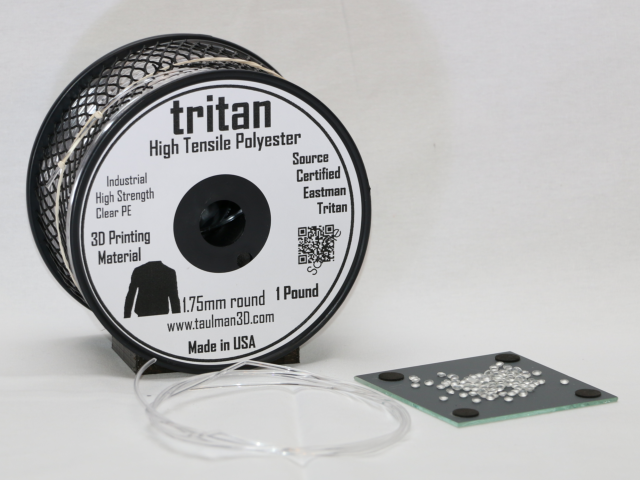

Tritan — a high tensile strength material with Tensile Stress (PSI) of 6,600 lbs, Modulus (PSI) 53,000, E@B was 18.7% “When 3D Printed”. The reports from testers continue to confirm that Tritan is the strongest material they have printed. To include bonding, bridging, non-stringing and extremely low warping.

PCTPE — A Plasticized Copolyamide TPE that is extremely flexible yet durable and strong. It is a TPE and nylon based material designed to be both highly flexible, yet retain the durability of nylons. PCTPE has a lower printing temperature than other taulman nylons and easily prints on any FDM/FFF 3D printer at only 225˚C – 230˚C. While extremely flexible the nylon ensures 1.75mm line is no problem for direct drive or bowdens feed systems. That determination was made by taulman testers as every sample of PCTPE sent out was 1.75mm.

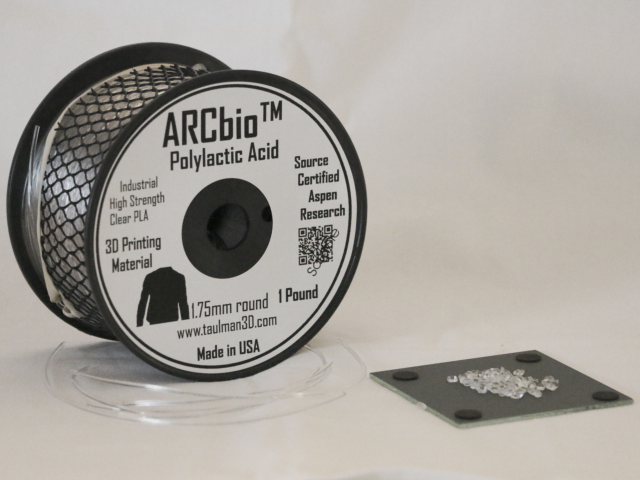

ARCbio PLA — is the result of a materials co-operation between Aspen Materials, a division of Aspen Research Corporation, and taulman3D. ARCbio is a new high strength, crystal clear PLA, biodegradable material. It is a new polymer developed specifically for its strength, clarity and light transmission. Aspen Research and taulman3D have worked to define the best combinations of viscosity and bonding specifically for 3D Printing. The natural colour of ARCbio is clear and Aspen Research has worked to develop a PLA the stays clear during thermal processing, thus eliminating the common “yellow tinge” seen in other PLAs. Unlike t-glase, ARCbio is more optically transmissive rather than reflective. Non-3DPrint testing shows ARCbio to be 5%-10% stronger than PET.

Tech-G — an extremely tough PETG polymer with full FDA approved raw polymer documentation and certification. Tech-G will be released as a technical “Fully Documented” material with the intent to provide engineers, design houses and industry with a material that comes with hundreds of specifications as to strength, chemical resistance, Worldwide certifications and technical data sheets. Working with one of the largest Chemical companies offering PETG variants, taulman has selected and tested the one chemical configuration that provides the best viscosity, lowest shrinkage and best bonding for 3D Printing.

Nylon 680 FDA — After almost a year of testing by users worldwide, nylon 680 FDA approved raw material polymer is ready for release. Nylon 680 is an extremely tough semi transparent line with one of the highest impact ratings and least shrinkage of all of the taulman3D nylon materials. Nylon 680 FDA will have “traceability” via QR codes. Furthermore, Nylon 680 is currently under evaluation for CE Dental use.

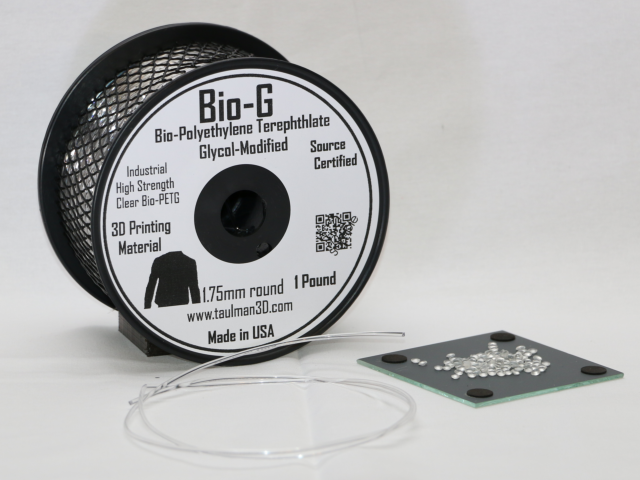

BIO-G — a new BPETG that has significant biodegradable features. It is a super tough polymer, one that you can count on to survive significant shock and resist harsh chemicals. BIO-G is relatively new on the market and has gone through significant testing to meet several certifications. Like all taulman3D materials, you can count on printing huge pieces with no delamination. It prints at ~238˚C on glass heated to 45˚C with a coat of PVA.

Taulman is working with a number of highly respected manufacturers to fulfill volume production to meet the very specific needs of the 3D printing community across all sectors of users. More details about the manufacturers and more in-depth specs on the ToolBox range can be garnered from the Kickstarter campaign here.

The materials are available in bundles that can be self-selected to meet your own specific needs. Taulman is also conducting a survey — inviting feedback from backers. All prices include shipping within the US but for backers outside North America additional shipping costs will be incurred — all clearly stated in the campaign. It’s just gone live so if you want to be among the early backers go take a look.