On Indiegogo right now, there’s a microboard seeking funding that will, if all goes well, help Makers handle their motion control projects — 3D printing, milling, laser cutting, etc. — with more power and efficiency. The T-Bone project just got an added boost from motor and motion control company TRINAMIC Motion Control, which will provide design support and manufacturing expertise to the group of Makers developing the microboard.

As the campaign video (embedded below) explains, 3D printers will usually have something like an 8-bit Arduino microcontroller that is responsible for handling all of the software data, as well as all of the motion control data. The T-Bone was designed to lift some of the burden off the 8-bit board. The T-Bone is a BeagleBone Black add-on card (or ‘cape’, as BeagleBone aficionados call them) that will aid 3D printers, and machines like them, in handling the power needed for motion control. A BeagleBone Black, if you’re unfamiliar, is sort of like a Raspberry Pi or, as TRINAMIC engineer Jonas Proeger puts it, “a powerful processor board that can easily run a G-code NC interpreter, Linux O/S and user and Internet interfaces.” So, how does the T-Bone lift the burden off the microprocessor? Jonas continues, “The T-bone will augment the BeagleBone with the required motor drives and real-time control software to complete an affordable and highly functional 3D printer.”

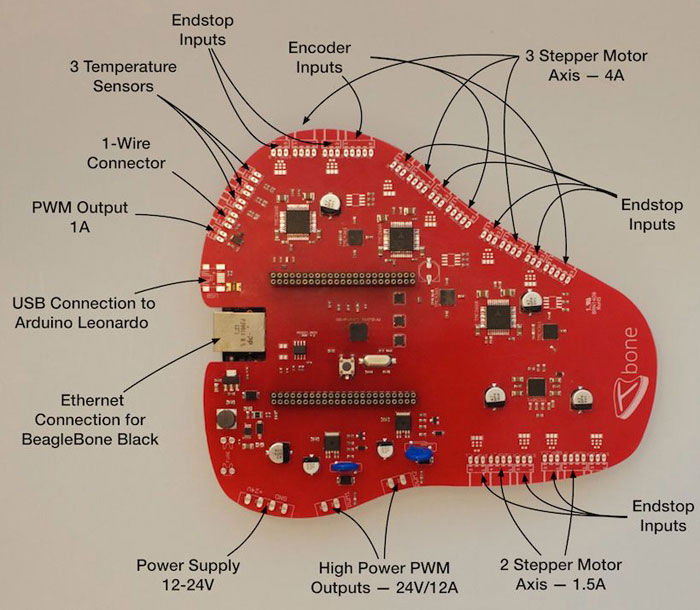

The cape, then, takes care of the real-time operation of five stepper motors for 3D movement and the extruder, calculating motor velocity, direction and acceleration, through the BeagleBone, which sends and receives data to and from the 3D printer and printing software. The BeagleBone is then freed up to handle the software, while the T-Bone takes care of the complex motion control. Altogether, the team behind T-Bone hope to increase the power of desktop 3D printers, at an affordable price. BeagleBone Black microprocessors are only $45 and a fully-assembled and tested T-Bone board, complete with software, is €89 (about $123). With an open source Mendel 3D printer (about $520), the total price would be around $700. In order to mass produce their boards, the T-Bone team is seeking €20,000 (about $27,600).

The T-Bone board is not for your plug-n-play machines, except maybe the Series 1 from Type A Machines (which has an accessible source hacking policy). If you’re already tooling around with RepRap kits and you want to free up your microcontroller so that your 3D printer can move faster and more efficiently, the T-Bone might be for you.

Source: Market Watch