A team of UK-based researchers have built a swarm of drones capable of working in tandem to accurately 3D print intricate concrete structures.

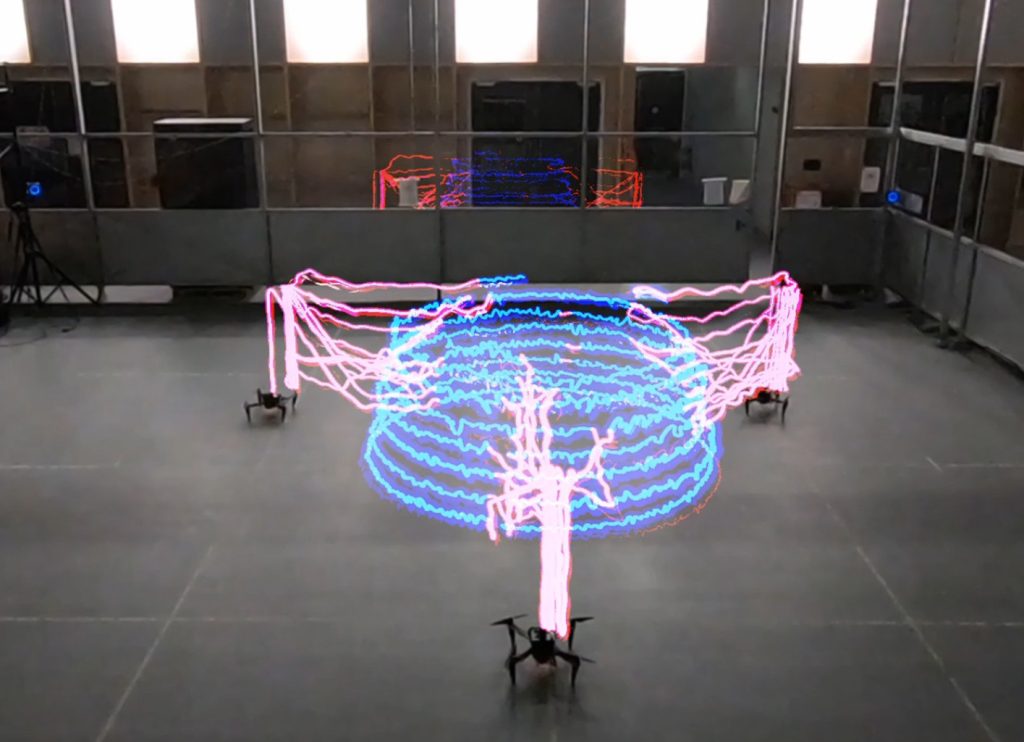

Believed to be the first example of a fully-aerial construction 3D printing framework, the team’s workflow sees scanning drones used to guide extruder-mounted drones to the right spot, and ensure any printed layers overlap.

Using this approach, the engineers’ ‘BuilDrones,’ equipped with custom printheads designed to account for aerial drift, have proven capable of autonomously creating robust tower and dome-like prints. With further R&D, it’s thought swarms of these robots could be deployed to build and repair infrastructure in remote climate disaster-hit areas, that traditional construction just can’t reach.

A nature-inspired swarm

Considerable research continues to be poured into the development of 3D printing-equipped robots and gantry-crane systems. The idea being that if deployed on a construction site, such machinery can help de-risk perilous tasks, and automate others in a way that drives potential productivity improvements.

However, in their paper, the Britain-based team highlight how these technologies currently require a “scaling up of robot hardware” to a “larger than desired manufacturing envelope.” This large footprint, the engineers say, makes the parallel operation of other machinery or people on-site “difficult and dangerous,” while power capacity limitations prevent their remote usage.

To get around these perceived issues, the engineers have turned to an unlikely source for inspiration: the wasp swarm. In their natural habitat, wasps work together to deposit material into nests in which their queen can lay eggs.

Building on this premise, the researchers have now constructed a swarm of their own, composed of 3D printing BuilDrones as well as ‘ScanDrones’ for guidance. In theory, the team says this ‘Aerial-AM’ framework enables “untethered, unbounded and scalable” construction to be carried out by multiple robots in tandem.

Realizing autonomous ‘Aerial AM’

To enable their swarm to fly autonomously and in unison, the researchers programmed drones to operate in two loops. In the first, BuilDrones are used to deposit a layer, before ScanDrones then validate this has happened successfully and guide the next layer, facilitating a process of context-driven deposition.

Once the team had provided these drones with the necessary real-time trajectory adaptation, material extrusion and print monitoring capabilities, they tested them at various scales. Initially, the engineers experimented with 3D printing a two-meter-tall structure made from rapid-setting foam, a material used deliberately due to its insulation and formwork applications.

Programmed around a model predictive control scheme, the BuilDrone proved capable of performing with sufficient precision to deposit the material while taking various flight trajectories. Over a 29-minute-long print cycle, the device also achieved horizontal and vertical accuracies of within 0.014m and 0.006m, leading the team to move on to more advanced testing.

Using a BuilDrone with a custom nozzle, designed to process a cement-polymer composite developed specifically for the build, the engineers then went on to construct an ultra-narrow cylindrical structure. As it turned out, the bots took over two hours to complete the 28-layer build as their capacity meant they required refilling after each layer, but they did so while compensating for layer deviation.

As such, the researchers believe they’ve “successfully validated the feasibility of Aerial-AM.” That said, the UK-based engineers say their study represents a “first step in exploring the potential of aerial robots for construction,” as support materials, post-curing and drone task-sharing remain obstacles to its success.

The 3D printing industry is full of start-ups seeking to disrupt the traditional construction industry with gantry-mounted concrete extrusion technologies. For example, one of the early leaders in this emerging space is COBOD, a firm whose gantry-based BOD2 construction 3D printer has been used in various projects, like the 3D printing of a home in Angola.

At a more experimental level, however, makers and researchers continue to trial other gantry-less approaches to construction 3D printing. RepRap enthusiast Torbjørn Ludvigsen unveiled a HangPrinter-built Tower of Babel in 2017. Instead of being mounted to a gantry, the system prints with a ceiling-suspended printhead, enabling it to overcome construction 3D printing volume restrictions.

More on the researchers’ findings can be found in their paper titled “Aerial additive manufacturing with multiple autonomous robots.” The study was co-authored by engineers based at Imperial College London, the University of Bath and University College London.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a concept rendering of the team’s drones 3D printing in a remote location. Image via Imperial College London.