Thousands of patients around the world could soon feel the benefit of 3D printing thanks to a new approach to producing Ankle Foot Orthosis (AFO), pioneered by students at Gonzaga University in Washington.

Additive manufacturing can change the face of prosthetic and orthotic medicine because both are stuck in the relative dark ages when it comes to fitting and producing new ones. It’s a time-consuming and expensive process that often requires multiple fittings. That’s inconvenient for the patient, as well as the doctors.

The AFO can prevent serious disability

An Ankle Foot Orthosis treats foot and ankle disorders in children. This sturdy brace holds the foot and lower leg in position. It provides a stable base, helps the child develop their motor skills and build strength in and around the joint. In some cases it really can fix the issue entirely by training the growth of the extremity and keeping the child on their feet.

Making an AFO is a complex process, though, and it takes a number of fittings. That includes scanning, molding, vacuum heat forming and fitting. It can take up to a month and costs as much as $2000.

In the developed world this is simply an essential expense. In poorer countries, though, this can rule out an AFO entirely and can leave a child to grow up with a serious and largely avoidable disability.

Students decide that it’s time for change

In 2015, a group of students at Gonzaga University decided to do something about it. They decided to implement rapid prototyping procedures that could cut the number of fittings and create a better AFO. The main goals were to “create a simple, easily 3D printed AFO with the best composition and geometry to meet strength and comfort requirements for patients.”

Removing the excessive fittings were one of the main goals and it achieved this with a 3D scanner to create a millimeter precise model of the patient’s leg and foot. Simply put, if the first model is right then the first fitting is the only fitting. That saves serious time and money.

Cheap plastics are the best

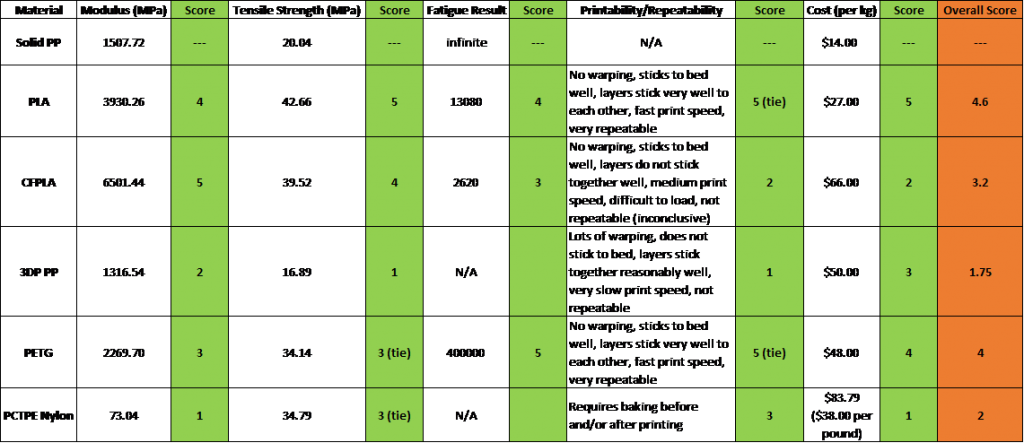

The students then experimented with materials, including PLA, Carbon Fiber-reinforced PLA, Nylon and PETG plastics. The cheaper the material that the students could use, the better it would be for the world at large. After weighing up the options, the students came back with good news and reported that PLA and PETG offer the best overall solution for an AFO.

“We want to 3D print large braces (up to 18 inches), and we need to print with a variety of materials as we research the best design for the braces,” says McKenzie Horner, one of the researchers at Gonzaga University. “3D Platform helped solve the problem by providing a versatile large-format 3D printer that helps us with our materials research and AFO printing.

“We were able to print a full-scale proof of concept immediately, and the open platform software capabilities allow us to prepare a print easily from a doctor’s 3D scan of a patient’s leg.”

Huge steps forward

The team of students managed to cut the fitting time from four weeks to just two days with rapid prototyping. They also slashed the costs and the experiment has been hailed as a massive success.

The students will continue to work on perfecting their AFOs and it’s good to see that 3D scanning and printing can have such a positive impact on the lives of tens of thousands people around the world.