When the same conference is hosting some of the most renowned and respected personalities in fields as diverse as architecture, gaming design and making you know something important is going to come out of it. In the era of multi-material 3D printing this no longer means just ideas and visions but actual, tangible objects set to lead the way to the future of design (intended as the ability to create new things). These are the focus of a collaboration between Stratasys and five world renowned designers.

The ACADIA conference, which is taking place in Los Angeles now (October 23rd to the 25th), and is setting the scene to do just that. Zaha Hadid, one of the top world architects will be there as a keynote speaker along with Will Wright, who might be less well known but is considered (and, having met him, I can confirm it) a genius and visionary in videogame design. (He created The Sims and the evolutionary videogame Spore). Neil Gershenfeld, “prophet” of the Fab Lab and distributed manufacturing concepts, will also attend to receive the 2014 ACADIA Award for Teaching Excellence.

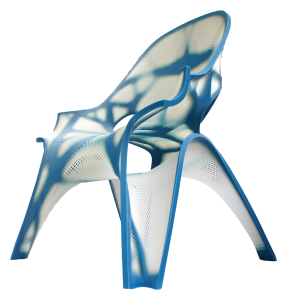

Zaha Hadid herself and her studio ZHA (Zaha Hadid Architects) have worked with Stratasys’ newest multi-density and multi-colour Object500 Connex3 to create a lightweight design chair that made use of its geometry, detailing and manufacture to highlight and improve its performance. Another designer implementing Stratasys’ polyjet technology in his idea of future furniture is Alvin Huang, who created the Durotaxis Chair. The “ovoid shaped” rocking chair is defined by a densely packed 3D printed wire mesh that utilizes Stratasys’ multi-material capabilities, due to its ability to 3D print in gradients of size, scale, density, colour, and rigidity.

Other works presented at ACADIA were inspired by a videogame-like ability to create objects by combining hundred of independent units into one, something that 3D printing enables for real-life structures. These include the Polynomio, a particularly intricate assembly that was developed by designer Jose Sanchez as single units that can then be organized in multiple ways, dependent on the creator, connecting gameplay and making personal creations.

Also present are Francis Bitonti with his “Molecule Shoes”. He sees 3D printing not just as a creative choice as much as a design philosophy that is emerging as a new industrial revolution. “As an architect and fashion designer – he explained – I was inspired to create something that encapsulates the point where we become connected to our environment, for example the part of a building where it hits the ground, as our foot does in a shoe – this is where the story of an object is told.”

Jenny Wu, the experienced architect who created the LACE collection of wearable designs, opted for FDM “I enjoy the possibilities that FDM 3D printing technology offers, as the strength of the materials enable me to directly manufacture jewellery pieces as opposed to just prototypes,” she explained.

Naomi Kaempfer, Creative Director Art Fashion Design for Stratasys, confirmed the company’s enthusiasm for working with Zaha Hadid Architects (ZHA) and the entire group of extraordinarily talented architectural and computational designers. “We are excited about the exploration of economical and playful use of smart geometries in these five unique designs – she said. “The translation of finite element analysis to create a spectacular finished form in the ZHA 3D printed chair, truly depicts the intrinsic aesthetics of digital manufacturing.”

Stratasys is now set to be one of the companies leading the transition of 3D printing from prototyping to manufacturing. For that to take place manufacturers need to be able to envision the creative possibilities opened by the ability to produce anything as a single object with different densities and colours in each of its parts, which thus requires no further assembly. The future will be made of 3D printed objects that are hard to envision for us today: that is the designers’ job and advanced technologies such as Polyjet are making it possible for them to start showing us what is possible — today.