Dr. Nicola Bizzotto, a young hand surgeon from Verona’s University Orthopedic Clinic, has been among the first in Italy to fully understand the possibilities that 3D printing technologies can offer in the medical field, especially their low-cost applications. To further explore the use of 3D printing within the Italian hospital system, he has worked with a team that includes Verona Clinic director Bruno Magnan and Dr. Pier Maria Fornasari, from a leading Italian orthopedic foundation, the Bologna Rizzoli Orthopedic Institute.

This collaboration is now consolidating into the IDBN (Italian Digital Biomanufacturing Network), an association that aims to unite all doctors who have an interest in applying AM technologies (including bioprinting technologies) in their personal area of expertise. The association, which will be officially launched next June, is the culmination of the work done over the past year in demonstrating the advantages that are made possible with 3D printing in the medical field, both in terms of the time and costs of surgery and medical education, and with respect to more efficient doctor-patient communication

Dr. Bizzotto is not new to the use of 3D printing in medicine and, in particular as a hand specialist, in orthopedic surgery. His experience with the Verona Orthopedic Clinic began about a year ago, when he obtained access to a Stratasys 3D printer and began experimenting with building solid representations of STLs obtained from CT scan data.

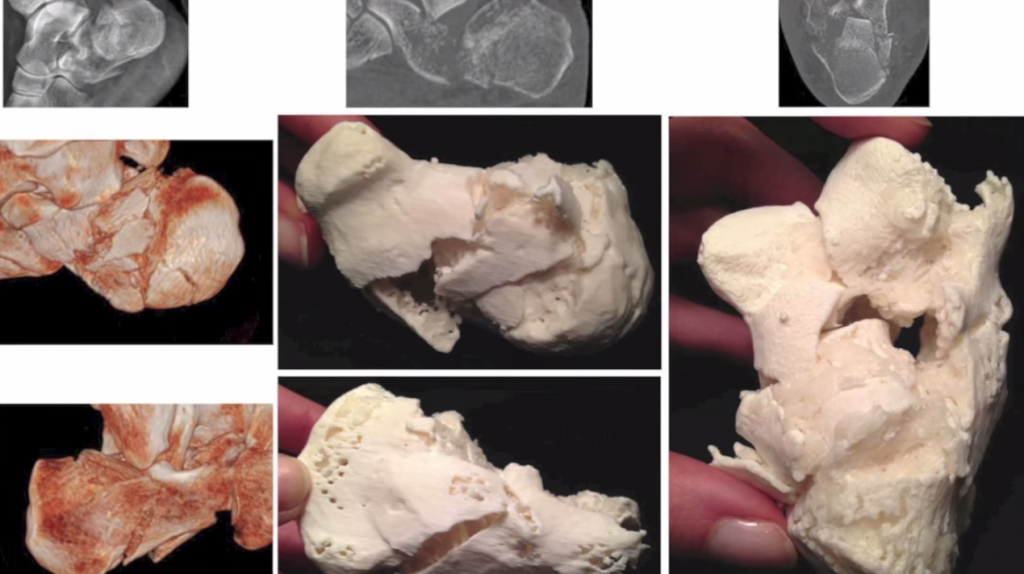

“The development of more powerful CT scanners in recent times enabled us to create 3D images and, from that, the move to physical 3D has been a logical step,” Dr. Bizzotto told me. “Creating the 3D printable STL files from the DICOM data is fairly accessible to anyone with a little bit of experience and the advantages are so extensive that there is no reason not to try it.” The first bones that were effectively reproduced were relative to the hip, the foot (specifically the calcaneus bone), and the knee of patients. “We believe that 3D printing is opening up incredible possibilities in the evaluation of fractures in these parts of the body.”

While he told me he personally uses the Osirix software for Mac, there are several tools for any platform (several of which are open source) able to export a CT scan as an STL file. 3D printing the bone using any 3D printer is fairly easy and can yield enormous benefits, as many doctors throughout the world are discovering. So, what are these benefits?

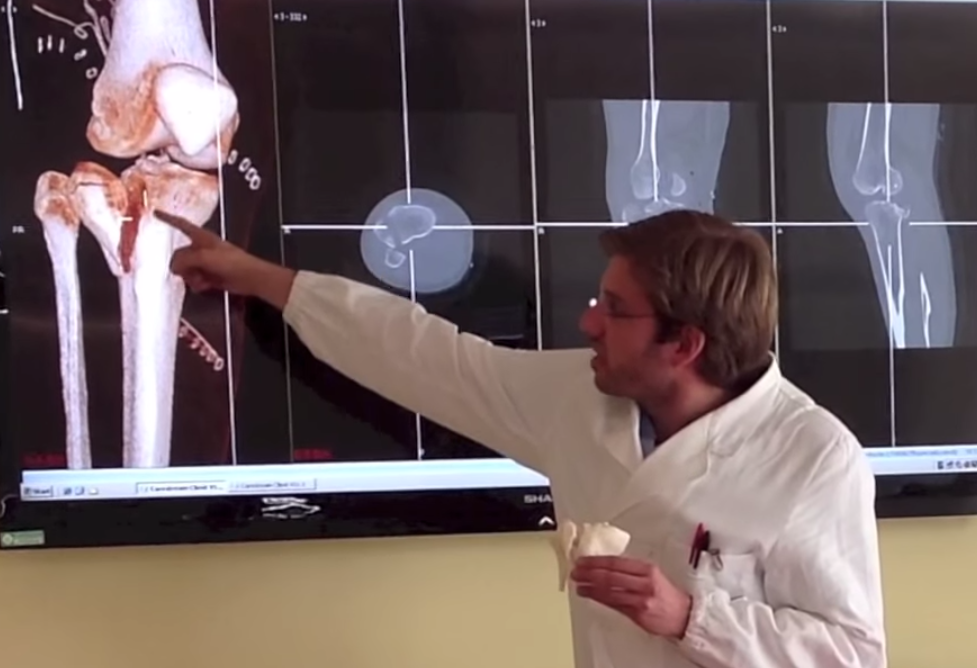

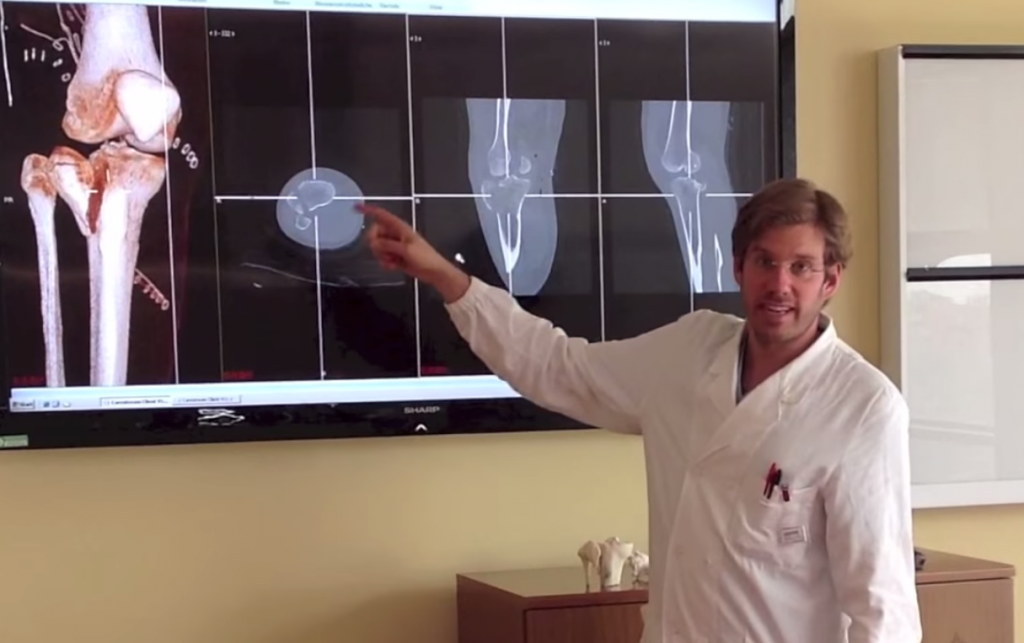

“The first is in medical education. The first times that I showed students perfect representations of bones, they were literally amazed. Learning about body parts from 1:1 physical representations of them is an entirely different experience than seeing them on a computer monitor,” Dr. Bizzotto explained. The second, which we have heard a lot about recently, is in pre-surgical preparation. “3D printing lets us reproduce a fracture or a lesion in a way that is virtually identical to the actual condition inside the patient, so that we can study every detail before beginning surgery. We are even able to use the model to simulate the operation we are going to perform,” he said.

This process can effectively reduce the time inside the operating room, thus lowering costs significantly, especially because, as Dr. Bizzotto explained, the 3D printed bones do not need to be made of any particular material, nor do they need to look nice: a basic white PLA or ABS will do the trick and, in many cases, printed support structures are not even necessary, nor is dual extrusion.

For Stratasys, a great supporter of Dr. Bizzotto’s initiatives, this may be a set back, since its machines are generally built for either high-resolution, complex parts or extremely high performance materials; however, the company is mostly interested in doctors adopting AM in their work, since this will inevitably lead to a more widespread awareness of the possibilities and the more complex medical jobs that require the company’s higher level 3D printers.

The third advantage, and possibly the one Dr. Bizzotto is most enthusiastic about at this point, is the improvements made possible in doctor-patient communication. “There is no doubt that the relationship with the patient changes entirely when they are able to actually see the physical model of the part we are going to operate on. These are opportunities that are available now and, with the lowering costs of machines, they can be implemented anywhere, bringing benefits to the entire healthcare system.” Making sure that his happens in the shortest time possible is the reason why IDBN was created.