Scott Sevcik, Stratasys vice president for manufacturing solutions, has revealed further details about the status of the Stratasys H2000 3D printer, demonstrated as the Infinite Build at IMTS 2016.

The machine, that literally turns FDM 3D printing on its side, is capable of making parts on a relatively limitless scale. It is finding a market amongst the maintenance, repair and overhaul (MRO) sector and with a number of OEMs.

Entering the stratosphere

Operating as a conveyor-belt style system, the minimum space required to house the H2000 3D printer system is 33 x 17 ft, with an additional 100 ft needed for supporting equipment.

The size of each unit however is entirely dependent on a customer’s requirements, and specifications are modified on a case-by-case basis.

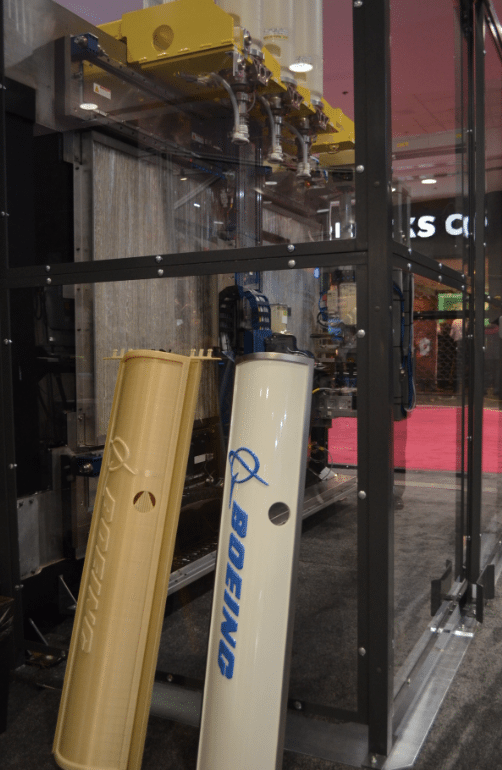

Multinational airplane OEM Boeing has been involved in many aspects of the project since its inception.

Speaking in August 2016, after the initial announcement of the Infinite Build, Leo Christodoulou, Director of Engineering, Materials and Structure at Boeing Company said the Infinite Build/H2000 system “Enables products to be made much larger and potentially unlimited length […]We look forward to a large ecosystem that offers large production, stability of processes and a robust base of design, materials and structures.”

Interiors today, exteriors tomorrow

The Ford Motor Company has also had an active input in the machine’s development, having using the H2000 to 3D print interior duct work and center consoles for its cars.

Speaking to MRO Network, a part of Aviation Week, Stratasys vice president for manufacturing solutions Scott Sevcik says, “With the material and repeatability advancements that we’re seeing with the technology today, we’re starting to move into some more critical components.”

“We’re moving toward secondary structures and some of the composite materials that have been developed. So today 3D printed parts are in interiors, but tomorrow they can go outside of the cabin and really into some very highly critical areas within the vehicle.”

3D printing for mass production

Sevcik adds that the goal now is to change the “economics” of how parts are 3D printed, moving away from a focus on hardware and material ability, and toward “the ability to stock digitally” and cut down inventories.

According to Jim Orrock, vice president and product leader at Stratasys, the company aims to sell 15-20 H2000 systems within the next two years.

Currently, Stratasys has one system that will be ready for installation after November 2017. After this, the average lead time of a new H2000 will typically be 6-9 months, and the company has the capacity to build two of the machines per quarter.

Full technical specifications of the H2000 3D printer system will be available August 31.

To be the first with all the latest H2000 news and other 3D printer releases, sign up to the most widely read newsletter in the industry, follow 3D Printing Industry on Twitter, and like us on Facebook.

Our 3D printing jobs site is almost ready for launch. Register for new opportunities here.

Featured image: Digital mock up of the Stratasys Infinite Build, now H2000 3D printer system. Image via MRO Network, part of Aviation Week.