Ford Motor Company has released a statement documenting its first few months with the Stratasys Infinite Build 3D printer. The industrial scale 3D printing technology is in use at the American car manufacture to 3D print large interior car parts at their Research and Innovation Center in Dearborn, Michigan.

Stratasys’ Infinite Build machine was first unveiled back in August 2016 and has been lauded for its ability to fabricate parts of infinite length. This collaboration between Stratasys and Ford was announced back in September along with a partnership with Boeing.

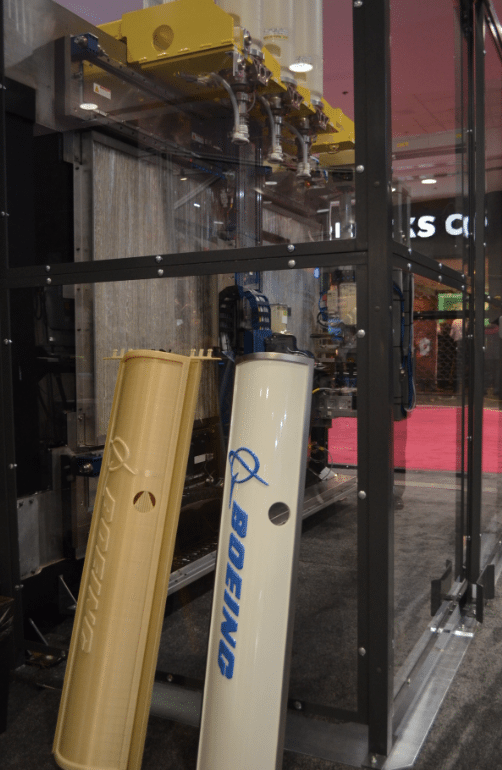

3D Printing Industry took a look at the Infinite Build at Chicago’s IMTS and spoke with the engineering team at the show. At the time, Stratasys representatives told us that they were printing “complicated duct work” among other things. However, since then it seems Ford has ramped up proceedings, as a new series of photos show the increasingly complex 3D prints made possible by the Infinite Build.

Lateral thinking

The machine prints laterally and, hence the name, is capable of creating parts of theoretically unlimited length. In addition to this lateral approach, the printer also has a micro screw extruder which, “can print a part at 10x what we could do with our traditional extruder” as Stratasys’ Dick Anderson told us last year.

In a statement from Ford today, Ellen Lee the technical leader of additive manufacturing research, said,

With Infinite Build technology, we can print large tools, fixtures and components, making us more nimble in design iterations. We’re excited to have early access to Stratasys’ new technology to help steer development of large-scale printing for automotive applications and requirements.

3D printing cars?

While the machine could print huge car panels, at its current stage is used as a rapid prototyping tool. The material used by the Infinite Build is a thermoplastic and therefore would be unsuitable for external car panels without further treatment. However, the technology has significant application in the creation of prototype designs and bespoke custom parts. In the longer-term the Infinite Build, or a future iteration, could form part of an Industry 4.0 enabled smart factory of the future.

The Infinite Build uses thermoplastic material in the form of micropellets. The size of sand, these pellets can be refilled automatically by the large robotic arm which means the Infinite Build could operate independently for days at a time.

Future of 3D printing at Ford

Ford anticipates the use of this technology to enable production of lighter-weight parts to improve fuel efficiency. Since, “a 3D-printed spoiler, for instance, may weigh less than half its cast metal counterpart.” However, for now Ford sees particular application for low-volume prototype parts or, “specialized race car components.” As recently reported, 3D Printing Industry saw how the Formula One industry is embracing 3D printing for these reasons.

Looking to the future, Ford announced early this year that it plans to expand its advanced manufacturing capabilities with a $4.5 billion investment. Following the cancellation of a proposed Mexican plant, the company intend to reinvest the money into manufacturing back in the USA. As the first automaker given access to this Infinite Build platform, Ford may have plans to incorporate 3D printing in their advanced manufacturing ambitions.

Sign up to the 3D Printing Industry newsletter for updates on 3D printing in the automotive industry. Also follow us on twitter and Facebook. Let us know what you think of the Infinite Build and whether you would drive a 3D printed car in the comments below.

Featured image shows the robotic arm capable of refilling the machine with more feedstock. Photo by Nick Miotke for CNET Roadshow.