Stratasys and SSM Health Cardinal Glennon Children’s Hospital, based in St. Louis, Missouri, have opened an advanced 3D printing “Center of Excellence”.

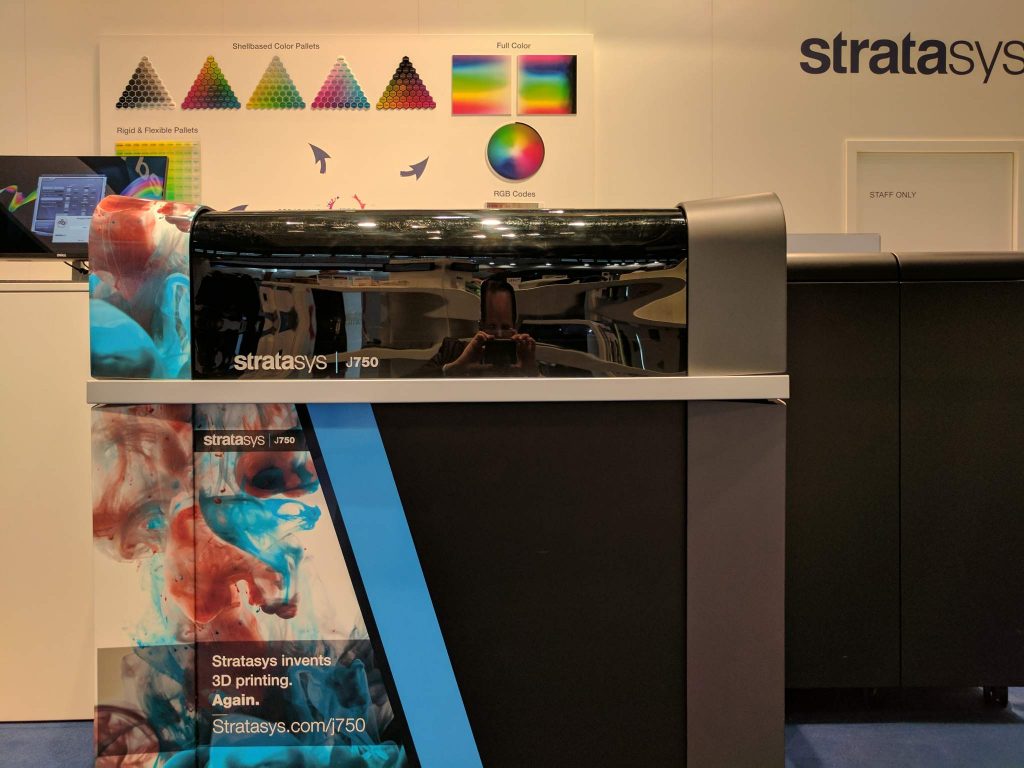

The pediatric academic medical center was named by the U.S. News and World Report as a “Best Children’s Hospital.” With the Stratasys J750 3D printer purchased by the hospital realistic, patient-specific anatomical models will be produced using Stratasys PolyJet technology.

The use of 3D printed medical models for surgical planning is advantageous due the high cost per minute of operating room time. Costs can range from $25 per minute to over $150, depending upon the complexity of the operation. A recent study by University of California San Diego and Rady Children’s Hospital found that by using 3D printing for surgical planning, an average $2700 saving per surgery.

A reduction in theater time can also lead to improved patient outcomes.

A gold standard for medical 3D printing

Steven Burghart, President of SSM Health Cardinal Glennon Children’s Hospital, said “As a leading pediatric care and academic research facility, we’re committed to continuous improvement by harnessing cutting-edge tools like 3D printing.”

Alexander Lin, MD, FACS, SLUCare plastic surgeon and co-founder of the 3D Printing Center explained that, “3D printing provides increased confidence in the operating room and results in a faster, more efficient operation.”

“In a recent plastic surgery reconstruction of a skull defect, we used a 3D printed intraoperative guide that matched the skull defect precisely. Without hesitation, we could use this guide to create a precisely shaped bone graft that perfectly matched the skull defect. In the past, this process would have been estimated, which can lead to longer surgery with higher risk of brain and blood loss, and a less precisely fitted reconstruction.”

Scott Rader, GM of Healthcare Solutions at Stratasys said, “To fully realize Dr. Lin’s vision of optimizing treatment, there needs to be greater collaboration between industry and thought leading institutions to create standards, best-practices and to develop the fact base on how to get the most from a hospital-based 3D printing program.”

Rader expects that the new Center of Excellence will become “the gold standard that demonstrates all that can be accomplished with medical 3D printing.”

For institutions without access to a Stratasys 3D printer, the company recently launched it’s BioMimics range of 3D printed medical models. This range of 3D printed bones, spines and hearts are intended for medical research and training, and made using Stratasys PolyJet technology.

We want to know the most notable medical applications of 3D printing. Tell us and make your nomination for the 2018 3D Printing Industry Awards here.

For all the latest 3D printing industry news, make sure you subscribe to the 3D Printing Industry newsletter, like us on Facebook and follow us on Twitter.

Featured image shows full color 3D printed anatomical hearts made by Stratasys. Photo by Michael Petch.