3D printed replica shark fins are aiding customs and law enforcement officials across South Africa to combat wildlife trafficking.

WILDOCEANS, a program belonging to South African non-profit WILDTRUST, the South African Department of Forestry, Fisheries and the Environment (DFFE), and TRAFFIC, a non-governmental organization focused on biodiversity conservation, have come together to provide front-line officials with a Shark ID Toolkit containing, among other things, 3D printed shark fins to help them identify illegally traded shark species.

The kits will be delivered as part of a series of training sessions to help law enforcement officials make better-informed compliance decisions to effectively curb the country’s illegal shark trade.

“The overarching objective of our project, made possible by the Shark Conservation Fund (SCF) is to increase protection for the species across South Africa,” Dr. Jennifer Olbers, WILDOCEANS Marine Biologist, told Good Things Guy.

“We are truly excited about what this training and all these tools will mean for the conservation of one of the most endangered taxa on the planet.”

The global illegal shark trade

The overfishing of sharks is a global problem, caused primarily by a huge demand for shark fins and a lack of management to ensure shark fisheries are sustainable. According to the WWF, as many as 100 million sharks are fished annually to supply the demand for their fins and meat, an act that is depleting and threatening populations worldwide.

As a result, more than 40 shark and ray species have been listed in Appendix II of the Convention on International Trade in Endangered Species of Wild Fauna and Flora (CITES). This listing requires permits to be issued that confirm shipments of shark products were obtained legally and sustainably.

However, shark fins can be difficult to identify on a species level, and illegal traders can use this to their advantage to falsely declare shipments of fins as being from species not listed on CITES. As such, frontline enforcement officials face a huge challenge in enforcing CITES due to being under-staffed and ill-equipped to deal with the high volumes of shark fins passing through land, air and seaports.

3D printed shark fins

TRAFFIC works across the globe to improve the trade of wild animals and plants in regards to biodiversity conservation and sustainable development. According to the organization, the vast majority of enforcement agencies have not been trained using real shark fins, and neither do they have access to them, which limits their ability to identify the fins of CITES-listed sharks.

TRAFFIC worked with Shark Scientist Charlene da Silva of the DFFE to explore the possibility of using 3D printed fins, based on real dried shark fins, to address this problem. Once funding was secured to conduct the necessary research and development processes through TRAFFIC’s ReTTA project, the development of the 3D printed replica fins brought on board multiple stakeholders from around the world.

Dried fins from CITES-listed sharks had been collected by Florida-based shark expert Debra Abercrombie for years, who used them for training customs and fisheries officials on the key identifying features of the fins. The fins from this collection and others were laser 3D scanned to provide a digital replica of each fin which was then optimized for 3D printing.

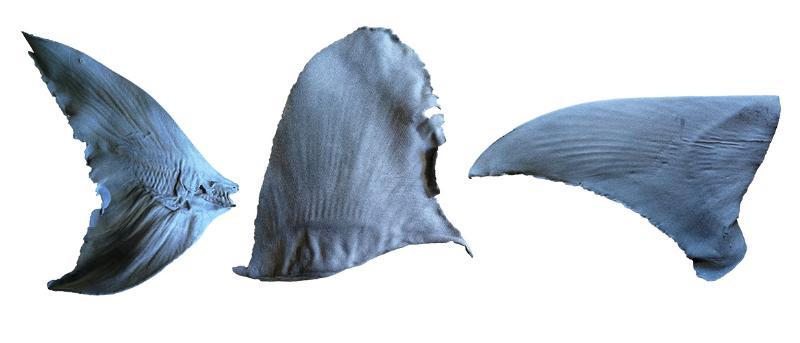

The fins were 3D printed in nylon using a selective laser sintering (SLS) 3D printing process. Sintered nylon provides a slightly rough sandpaper-like texture similar to that of real dried shark fins. The fins were then painted, which according to TRAFFIC was the most challenging part of the project, due to the need to ensure accurate colors and markings for identification purposes.

The 3D printed fins also contain the name of each shark along their leading edge and a raised square section to which QR codes can be attached. These QR codes are linked to dedicated web pages that provide the key identifying features for each species.

Protecting wildlife with 3D printing

While wildlife conservation is perhaps not the most obvious application for 3D printing, there have been a number of initiatives that have harnessed the technology to help protect endangered species and combat illegal trade.

For instance, researchers from the Canadian École de Technologie Supérieure (ÉTS) and Université de Montréal recently 3D printed protective ‘crowns’ for the tusks of an endangered walrus at a nearby aquarium. The team produced metal caps fitted exactly to the walrus’ tusks to prevent them from becoming vulnerable to dental abscesses.

Elsewhere, the University of Kent and conservation organization Paso Pacifico 3D printed a set of decoy sea turtle eggs with embedded GPS trackers in Costa Rica and placed them in more than a hundred birds nests. Once the eggs were stolen, the researchers were able to track the illegal traders and identify potential routes towards their intervention in a crime-fighting initative to prevent the illegal theft and trade of sea turtle eggs.

3D printing has also been deployed as a novel method of repairing a coral reef in Hoi Ha Wan Marine Park in China. A team from Hong Kong University designed and 3D printed 128 hexagonal clay tiles customized to encourage coral attachment and deployed them in three sites around the bay. Observing their artificial reef over the next 18 months, the team hopes the project could present an effective method of preventing coral reef deterioration across the region.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows replica shark fins after painting (Bowmouth Guitarfish (Rhina ancylostoma) caudal fin, Oceanic Whitetip Carcharhinus longimanus dorsal fin, and Great Hammerhead Sphyrna mokarran pectoral fin). Image via TRAFFIC.