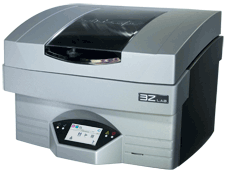

Solidscape, a leading manufacturer of high precision 3D printers for direct manufacturing applications, recently announced the launch of the 3Z™ LAB 3D wax printer — designed and specifically developed for dental labs.

“We worked with dental lab owners on developing the 3Z LAB printer. It’s designed to help lab owners hold down rising costs while remaining competitive against offshore pricing. With a breakthrough price of $25,650, the 3Z Lab provides a significant cost-per-case advantage.” Fabio Esposito, President, Solidscape, Inc. commented.

The 3Z™ LAB 3D printer has one touch functionality that enables dental lab technicians to easily produce wax-ups ready for casting and pressing with highly accurate marginal integrity, occlusion, contact and anatomy form. The 3D printer is designed to produce crowns, bridges and copings with high accuracy in order to provide patients with a perfect fit.

The wax materials used by the the 3Z™ LAB 3D printer are Solidscape’s next generation materials that are reportedly the strongest and the most durable ever. 3Z LabCAST and 3Z LabFill materials are specifically formulated for dental wax-ups retain the precision and smooth finish characteristics that are required for successful investment casting.

According to Fabio Esposito, “The 3Z LAB printer offers an effortless, affordable digital workflow that delivers high casting yields, consistent turnarounds and low cost-per-parts economy. Now lab owners have a clear choice that matches their performance needs with an affordable solution.”

Source: Solidscape