The 3D Printing Industry Awards 2022 shortlists are now available for voting. Who will win the 2022 3DPI Awards? Have your say by casting your vote now.

Metal 3D printer manufacturer SLM Solutions has developed a new large-format system that allows users to produce parts at a “record-breaking” scale.

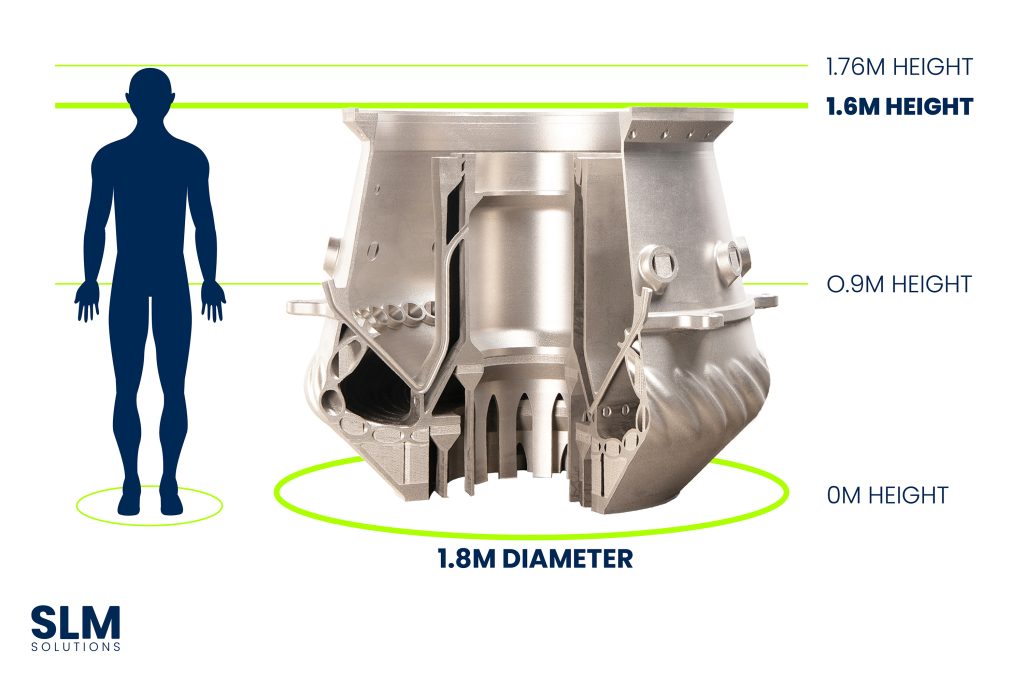

As yet unnamed, SLM Solutions’ latest powder bed fusion (PBF) printer features a whopping 3.0 x 1.2 x 1.2 meter build volume, enabling it to rapidly produce cylindrical parts up to 1.8 meters in diameter and 1.6 meters in height. Announced at Formnext, the machine closely follows the launch of the NXG XIIE 3D printer, and the firm says it’s now likely to be a “game-changer” for large component manufacturers.

“This opens up new possibilities to transition applications to additive manufacturing (AM) by removing previously accepted geometrical restrictions,” said Sam O’Leary, CEO of SLM Solutions. “Every piece of technology we develop is testament to our incredible team of relentless innovators, who solve our customers’ manufacturing challenges and change the future of manufacturing forever.”

SLM Solutions’ large-format portfolio

Based in Germany, but with offices in Canada, China, France, India, Italy, Japan, Singapore, South Korea, and the US, SLM Solutions specializes in developing PBF 3D printers. While the firm markets systems in several sizes, including the SLM 125, SLM 280, SLM 500 and SLM 800 at the smaller end, it has increasingly targeted larger-format applications.

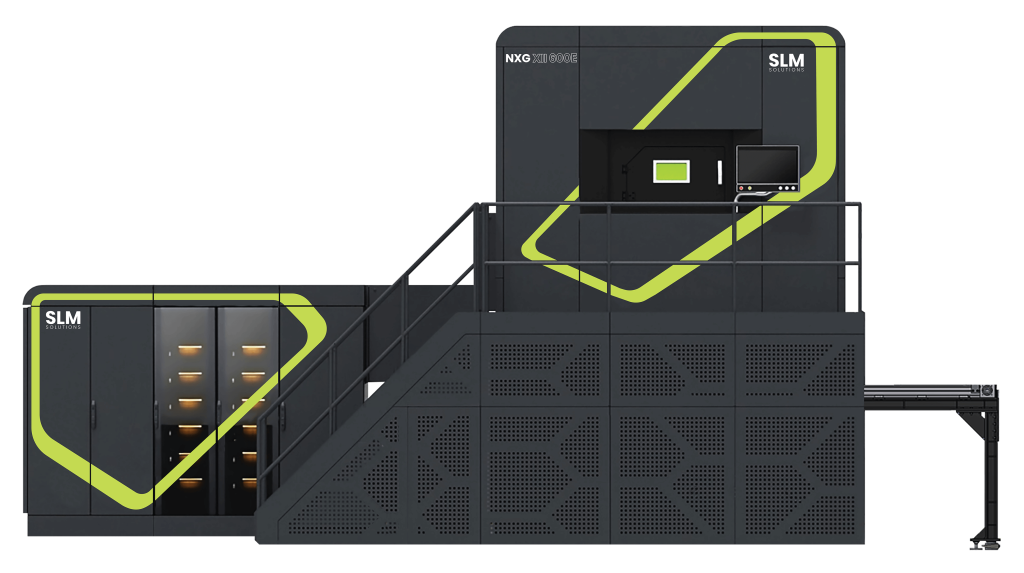

Shortly after launching the NXG XII 600 system at Formnext Connect, SLM Solutions signed an MoU to sell five of the 3D printers and it continues to see strong demand, particularly from automotive clients like Divergent Technologies.

Since then, the company has been subcontracted by the Concurrent Technologies Corporation to develop the ‘world’s largest’ metal 3D printer for the US Air Force. This larger variant of the NXG XII 600 features a 1.5-meter Z-axis, which allows it to manufacture much longer parts with potential critical defense applications.

Nikon’s takeover of SLM Solutions is now reported to be on the verge of conclusion, but it seems that in light of its latest large-format 3D printing announcement, the company remains focused on targeting PBF at an unprecedented scale.

AM at an “almost unbelievable” scale

Though SLM Solutions has kept many of the details about the newest addition to its portfolio under wraps, it’s a safe bet that it’ll be based around a similar PBF technology to the rest of its machines. Said to be composed of a core unit with an adjustable build envelope, the system’s main differentiators are likely to be its part adaptability and capacity.

The machine’s adjustable build volume allows for the manufacture of components in individual dimensions, thus enabling users to tune their setup to meet use-case-specific requirements. What’s more, the system does so while expanding the limits of metal 3D printing with its huge capacity, which unlocks the production of parts that were previously impossible to print using existing PBF solutions.

As well as facilitating the 3D printing of objects up to 3.0 x 1.2 x 1.2 meters in size at a build rate of up to 330 cm³/h, the unit is said to provide the same benefits as the firm’s other machines, enabling part consolidation and freedom of design.

It’s still unclear how close a resemblance the new system will bear to SLM Solutions’ other large-format NXG XII 600 and NXG XIIE 3D printers. However, O’Leary says the machine’s launch doesn’t just represent an expansion of the company’s portfolio, but a “real revolution of manufacturing” that enables 3D printing at an “almost unbelievable” scale.

Like so many buzzwords in 3D printing, the phrase ‘record-breaking’ is one to be taken with a pinch of salt, especially when the technology is continually being scaled across the industry. MELD and Ingersoll Machine Tools’ metal 3D printer, for instance, is set to be large enough to create huge military vehicle parts for the US Army. Earlier this year, Sciaky also unveiled the world’s largest electron beam 3D printer, which is capable of creating six-meter-long aerostructures.

Elsewhere, in the world of PBF, GE’s ATLAS 3D printer features a 1,000 mm³ build volume. Hailed at launch as the ‘world’s largest additive machine,’ the ATLAS enables the production of massive aerospace, automotive and oil & gas parts.

Check out our full Formnext news round-up for the latest from 3D printing’s leading trade show.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a diagram indicating the scale of the parts made possible by SLM Solutions’ new 3D printer. Image via SLM Solutions.