German 3D printer manufacturer SLM Solutions is set to sell five of its large-format NXG XII 600 systems after signing an agreement with an unspecified “major European OEM.”

The Memorandum of Understanding (MoU) will make the unnamed customer one of the first adopters of SLM’s powerful new 12-laser machine. Although SLM remains tight-lipped about its client’s identity, it did reveal it is a “global company” that intends to enter “serial production” when the system is installed in 2022.

“This MoU just two months after the launch is an exciting milestone for the company,” said Sam O’Leary, the newly-appointed CEO of SLM Solutions. “It validates our vision that the OEMs can implement innovative additive manufacturing technology for serial production into their business models.”

“When we launched the NXG XII 600, we knew it would disrupt the industry and spark a new era for manufacturing.”

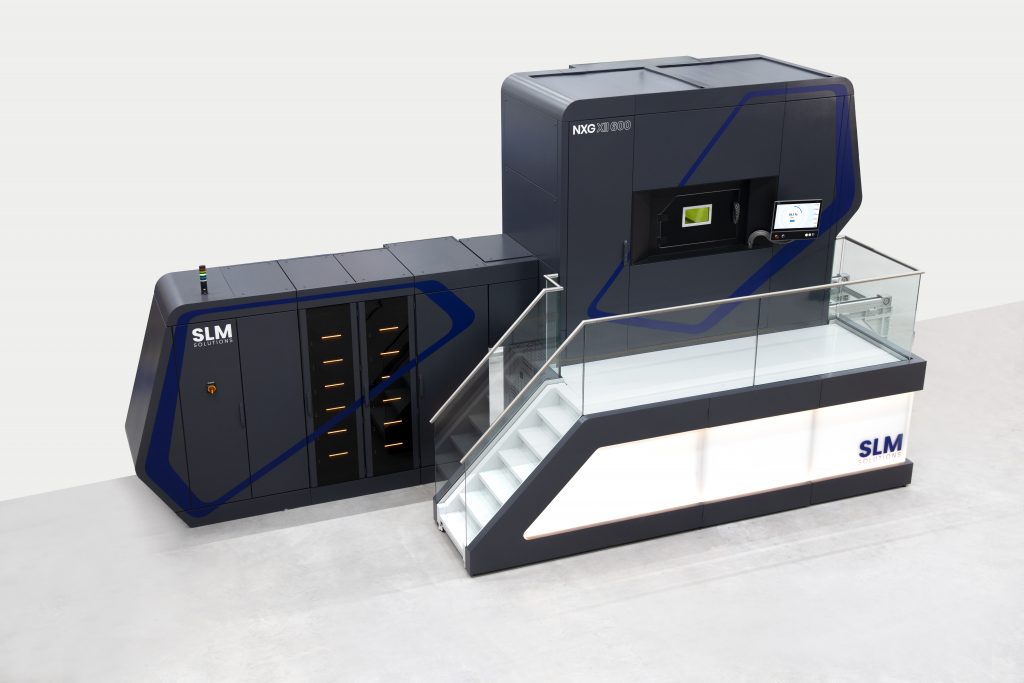

SLM’s mammoth NXG XII 600 system

Based in Luebeck, Germany, SLM is known as a specialist in developing Selective Laser Melting (SLM) 3D printers. Until last year, the firm’s machine portfolio included its conventional SLM 125, SLM 280, SLM 500, and SLM 800 systems, but at Formnext Connect, it unveiled the significantly faster and larger NXG XII 600.

SLM’s souped-up system features twelve 1 KW lasers that, when operated together, make it twenty times faster than the single-laser SLM 280. The NXG XII 600 also includes a huge 600 x 600 x 600 mm build volume, enabling it to produce large-format parts, and meet more demanding applications in the automotive and aerospace sectors.

Having agreed to sell five of the machines to an unnamed client, and signed a beta contract with a different customer for delivery in Q2 2021, O’Leary now claims that metal 3D printing is ready to be deployed within serial production settings.

“The NXG XII 600 accelerates the future of metal AM, and our engineers have further pushed the boundaries of what is possible,” said O’Leary. “This MoU underlines that not only are we prepared to step forward to the industrialization of metal additive manufacturing, but the marketplace is ready as well.”

Applying the NXG XII 600

Even though SLM has revealed very little about its MoU, the company has established strong links with its German automotive neighbors. It would therefore be unsurprising if a car manufacturer turned out to be SLM’s mystery client, especially seeing as it 3D printed a concept drive housing for Porsche just last month.

Similarly, although Bugatti is based a little further afield, SLM has 3D printed brake calipers for the firm before, and the car maker recently fabricated parts for the Bugatti Bolide as well. Of course, this doesn’t necessarily means that SLM’s client is automotive-based, but given the large order, it’s likely to be a repeat customer that is already familiar with the metal 3D printers.

Aerospace represents another key market for large-format metal components, and SLM has formed strong ties in aviation too. For instance, working with Honeywell in July 2020, the firm developed a parameter set for 3D printing aluminum F357, which could effectively form a basis for future industry-standard parts.

Overall then, SLM has traditionally targeted the aerospace and automotive verticals, so selling into these industries would fit into its broader market strategy. SLM has also said that its client is a “global company,” and many of its neighbors in the nearby industrial heartland of Munich could easily fit that description.

Taking-on the large-format market

While the sizable build area of SLM’s new machine is no doubt conducive to creating big parts, it also faces stiff competition from the industry’s other large-format manufacturers.

Additive Industries, for instance, announced its latest flagship MetalFAB-600 3D printer in November last year, complete with a 600 x 600 x 1000 mm build volume. The machine features ten 1KW lasers, two less than SLM’s new system, but it’s still one of the biggest and most powerful metal 3D printers on the market.

Other companies, such as Intech Additive Solutions, manufacture large-format LPBF machines, and the OEM recently launched its iFusion LF series of metal 3D printers. With build volumes of 450 x 450 x 450 mm, the new systems are designed to address the needs of aerospace, automotive and engineering clients.

On a more experimental note, 3D systems has also revealed details about the ”world’s largest metal 3D printer” it’s developing for the U.S. Army Research Laboratory (ARL). The nine-laser system includes a massive 1m x 1m x 600mm build area, potentially enabling the fabrication of huge aerospace parts on-demand.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows SLM Solutions’ new NXG XII 600 3D printer. Image via SLM Solutions.