Germany based Metal 3D printer manufacturer SLM Solutions and Israeli 3D printing software provider Assembrix, have announced the next stage of their ongoing partnership to develop secure remote printing capabilities and protect customer intellectual property (IP).

This latest announcement follows the news last year that Assembrix’s Virtual Manufacturing Space platform (VMS) had been successfully integrated into SLM Solutions’ machines. Building on this, both companies are now looking to their next development phase of secure remote printing, by utilizing state-of-the-art blockchain and encryption technologies.

A blockchain is a decentralized digital ledger that can securely store data and information across a network of machines. Both companies hope that this latest step will further strengthen their integrated software, and are now looking to deliver industrial-scale availability in the future.

Nanyang Polytechnic’s Additive Manufacturing Innovation Centre has already adopted this technology.

“By leveraging secure cloud-based solutions, more manufacturing companies can explore remote arrangements while upholding the highest quality control standards,” commented Zaw Hlwan Moe, Manager at Nanyang Polytechnic’s School of Engineering. “Technological advancements like these can significantly boost productivity in the additive manufacturing industry.”

Assembrix CEO Lior Polak added that, “With the increasing demand for secure distributed manufacturing solutions, the ‘Assembrix inside’ integration with SLM Solutions sets the new standard, providing the most secure solution available. It brings substantial value to manufacturers worldwide, reducing costs and mitigating risks.”

SLM and Assembrix’s VMS software

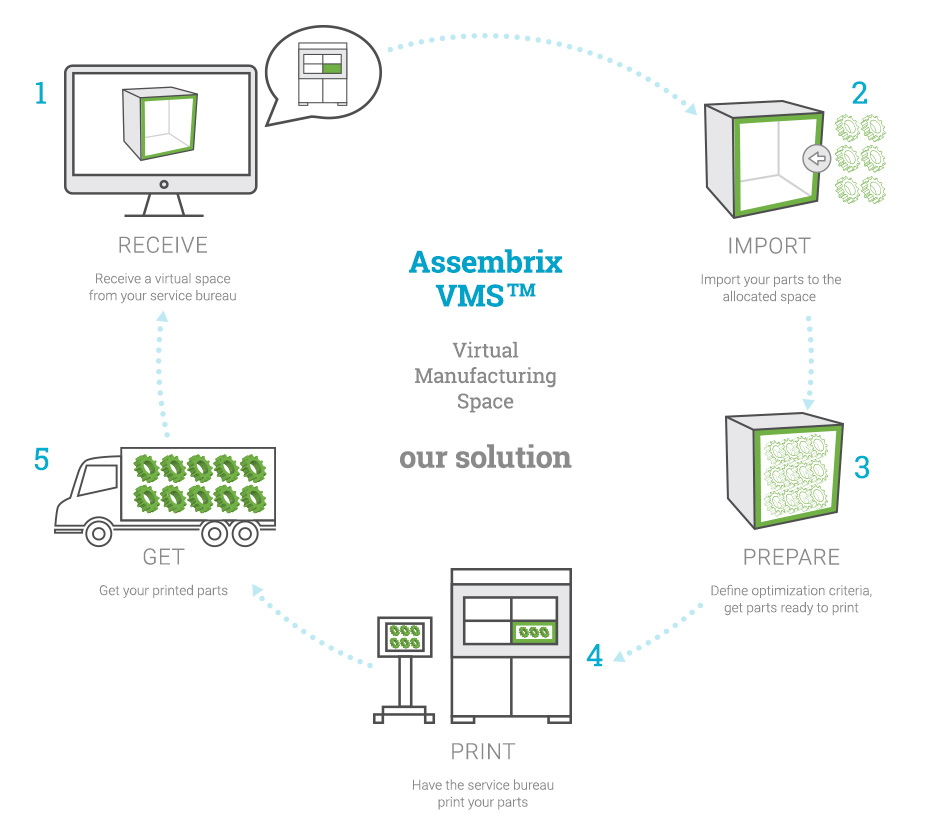

Assembrix’s VMS software is a cloud based platform that virtualizes the industrial 3D printing process, enabling remote printing while maintaining high security standards. According to Assembrix, VMS both simplifies and secures the entire additive manufacturing process, from design to production and beyond.

In February of last year, it was announced that Assembrix VMS had been successfully integrated into SLM Solutions machines worldwide. Through this integration, customers can stay updated on their printing status, while IP is protected through advanced encryption technology.

“The productive partnership between SLM Solutions and Assembrix empowers customers to fully leverage secure remote printing processes, supporting their distributed manufacturing strategies,” claims Nicolas Lemaire, Software Product Manager at SLM Solutions. “It enhances SLM Solutions’ growing software and service solution portfolio, establishing itself as the leading additive manufacturing technology in the market.”

This latest announcement suggests that new blockchain and encryption technology will be incorporated into Assembrix and SLM’s offering, providing even greater IP protection and security to customers. For the next phase of the project, both companies are looking to expand this offering into an industrial-scale solution.

Additive manufacturing and the blockchain

The protection and security of IP within 3D printing is not a new concern. Indeed, the primary cybersecurity risks within additive manufacturing typically center around IP theft and process sabotage. This is generally conducted through the breaching of cloud-based file-sharing systems and the tampering of CAD files. As a result, blockchain technology has received growing attention from within the additive manufacturing industry as a means of securing the digital thread of 3D printing.

Last April, researchers from the University of Exeter Law School patented a watermarking technology which they claimed would “revolutionize” the distribution, traceability, and searchability of 3D printed objects. The team also stated that they were working towards linking this watermark technology with blockchain to ensure greater IP protection. “By using blockchain you can enable new technical standards for licensing and use around the world by creators and companies,” said project lead Dr. James Griffin.

Moreover, the U.S’ largest 3D printer network using blockchain technology is currently being developed as part of Automation Alley’s Project DIAMOnD (Digital, Independent, Agile, Manufacturing on Demand). This project is being developed to help Michigan manufacturers scale up their Industry 4.0 activities, and further “democratize” additive manufacturing.

Tackling unauthorized reproduction of 3D designs is also the focus of Physna/Thangs, as our recent interview with Physna CEO Paul Powers detailed.

Subscribe to the 3D Printing Industry newsletter to ensure you keep up with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows SLM Solutions’ SLM 500 3D printer. Image via SLM Solutions.