To the uninitiated, Thangs might seem like only a 3D file-sharing platform. A destination for those seeking 3D printing files, full of fanart and popular 3D models from designers. 3D Printing Industry spoke with the founder and CEO of Physna, the enterprise behind Thangs, about the company’s novel proposal and how they plan to use AI in a way that may surprise designers.

“We need to make some of the features clear,” says the Thangs founder.

In this exclusive interview, Physna CEO Paul Powers unpacked the firm’s unique geometric deep-learning technology and a new Thangs offering that allows designers to earn a living from their work. Speaking from his office in Columbus, Ohio, Powers gave us an insider’s view of the digital tools that have been shaking up the 3D printing industry.

Thangs and Physna: What’s the Link?

Physna, short for “physical DNA,” is a Sequoia-backed company making a mark on the tech landscape from an unexpected location. “We are a little unusual for a Sequoia-backed company – being in the middle of nowhere versus out in the bay area,” said Power, adding, “But you know what? Ohio is a great place to live. It has a lower cost of living.”

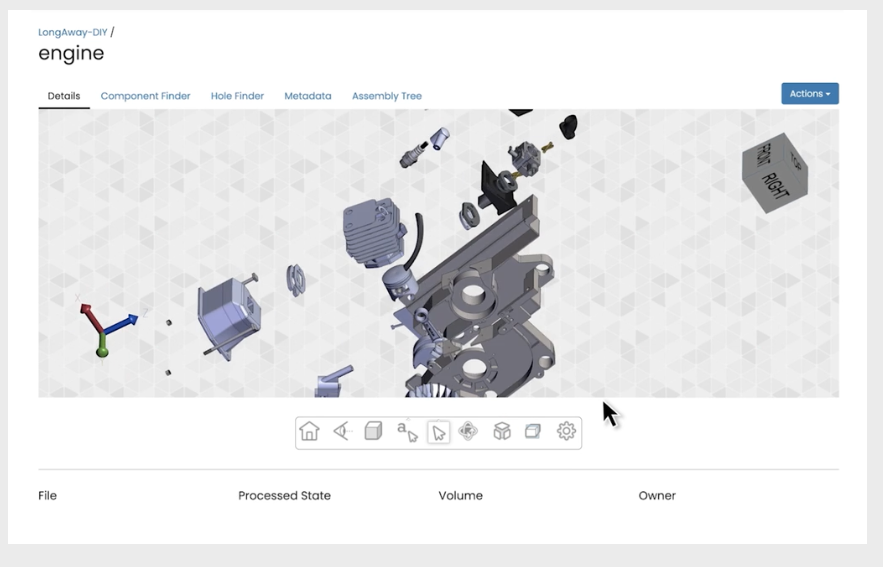

Physna’s core technology goes beyond storing STLs. It translates 3D models into a code that software can understand. But this isn’t just any code – it’s normalized, allowing matching between corresponding geometry within different 3D models. This leads to some remarkable capabilities, like identifying common components between different motor models, or suggesting alternative parts that could be used in a build.

“It’s kind of like doing the same thing you can do with text in terms of a search and a query or comparison or analysis, but it’s doing it with the geometry of the model,” explains Powers.

What’s more, this works across file formats and disciplines, meaning a 3D scan, a CAD model, or a CGI design can all be compared. “We can match between all these models, show you what they have in common, what’s different about them, and also where these parts go,” said Powers.

The real-world applications of this technology are wide-ranging. For instance, a company might have a 3D model of a valve assembly they’re producing. With Physna’s technology, they can upload this model and immediately identify all the components needed to build it in real life, irrespective of how differently tagged models might label those parts.

The interview also brought news about Thangs, a Physna-owned 3D search engine. Thangs is more than just a showcase of Physna’s technology – it also represents an avenue of monetization for the firm, and has a growing community of 3D designers seeking a refuge from theft. More on that later.

“By showcasing what Thangs can do, it also shows corporations, government agencies, etc., just how powerful that technology is,” said Powers. And this is only the beginning. The tech showcased on Thangs is set to become even more advanced as the company rolls out its enterprise applications, focusing on specific customer models and leveraging AI for machine learning.

One of the major application areas is supply chain optimization. “We can standardize everything into this one part, and we can order that from any one of these 50 vendors versus relying on all 50. Now you’re saving money and you’re also much more resilient because you have 50 options instead of 50 dependencies,” Powers explained.

By using Physna’s geometry search, designers can also streamline their workflows, as the technology can predict what they’re in the process of creating. This can help prevent unnecessary rework and even offer a starting point for new designs.

MS Clippy for 3D Design? “It looks like you’re designing a manifold….”

The company currently offers a Thangs add-on for Blender, a popular free and open-source 3D software toolset, and they are looking to expand by adding integration with other popular 3D design software.

“We started off with Blender because the market has been growing so rapidly. It’s increasingly being used across disciplines like 3D printing and animation. However, our goal is to expand beyond that and have plugins for every major 3D design system out there,” said Powers. “If you’re a designer, you can use that … as an auto-fill capability.”

I likened Thangs’ Blender plug-in to Microsoft’s Office Assistant, Clippy. While this initially seemed to baffle Powers, he ultimately conceded the comparison was somewhat accurate, although he emphasized that the solution is more precise and advanced.

“We aim to solve a crucial problem that engineers often face – it’s hard to have a normalized way of saving these models. Traditional methods don’t really offer a way to identify if you’re redesigning something that’s already been designed. With Physna, we allow engineers to search before they begin the design process, preventing them from redesigning the same thing over and over again, which also helps to prevent supply chain issues,” explained Powers.

When asked about the future software integration on their roadmap, Powers emphasized that user feedback and community needs would guide their decision, underscoring the company’s user-centric strategy.

In terms of the 17 million models available on Thangs, Powers shared that they come from various sources, including user uploads and third parties. As Powers puts it, “Thangs is essentially like Google for 3D. It crawls the web, finds 3D models, analyzes them, and provides search results.” He did point out, however, that the exact proportion of user-uploaded models versus third-party models was unclear due to a surge in uploads.

Powers attributed that impressive increase in uploads to an increased focus on creators. “There are two major types of creators that we see on the platform: influencers with large followings, usually in the 3D printing space, and collaborative teams of engineers and designers who use Thangs for its version and revision control, almost like GitHub for 3D.”

Concluding this section of our conversation with a flourish, Powers offered a succinct way to describe the offering: “Thangs is essentially a GitHub plus Google for 3D.” It’s a brief but potent summary of the technology Physna brings to the 3D world, catering to creators, influencers, and collaborative teams alike.

What Do 3D Designers Think About Thangs?

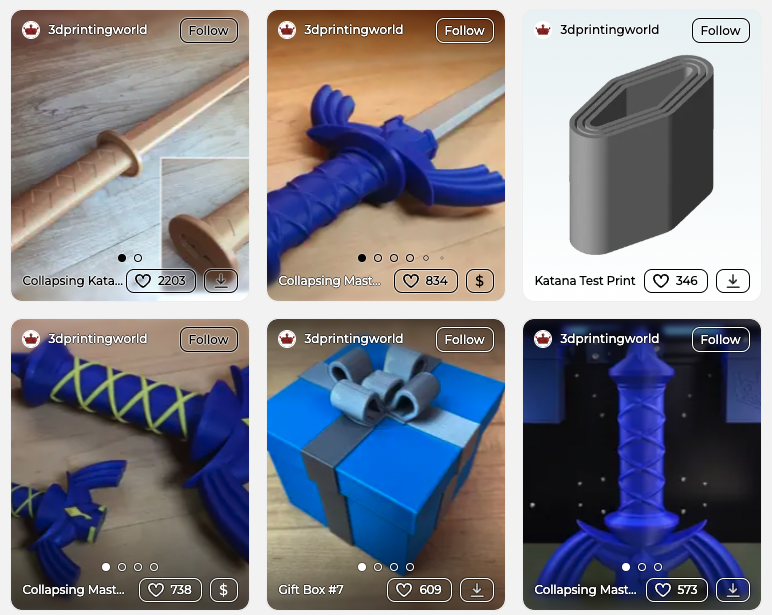

I asked several 3D designers using the Thangs platform for their thoughts about the plaform. John Mulac, an experienced design engineer, shared his journey into the 3D design and printing world. Originating from a background in custom machinery design for an automation company, Mulac’s encounter with a coworker’s 3D printer ignited his interest in the craft. This newfound fascination led him to purchase his own 3D printer and explore the boundless possibilities of 3D printing, from intricate models to elaborate machine parts. Today, Mulac utilizes his passion both professionally and personally, noting that 3D printing allows for the materialization of virtually anything he can imagine. He posts on Thangs under the handle 3D Printing World.

Mulac went on to explain his relationship with Thangs, a platform where he hosts his designs. Mulac first learned about Thangs after the platform’s staff handled a copyright infringement issue promptly and competently, and he quickly came to appreciate its distinctive features. These include the ability to track design revisions and identify models on other sites. But the number one reason to use Thangs for Mulac? “My absolute favorite thing about Thangs is the positive and uplifting community they and the users have built over the last couple of years,” he says. Discussing the impact of 3D printing on his projects, Mulac emphasized its potential to enhance complexity in designs without drastically affecting manufacturing costs, an advantage he relishes, especially when working on personal projects.

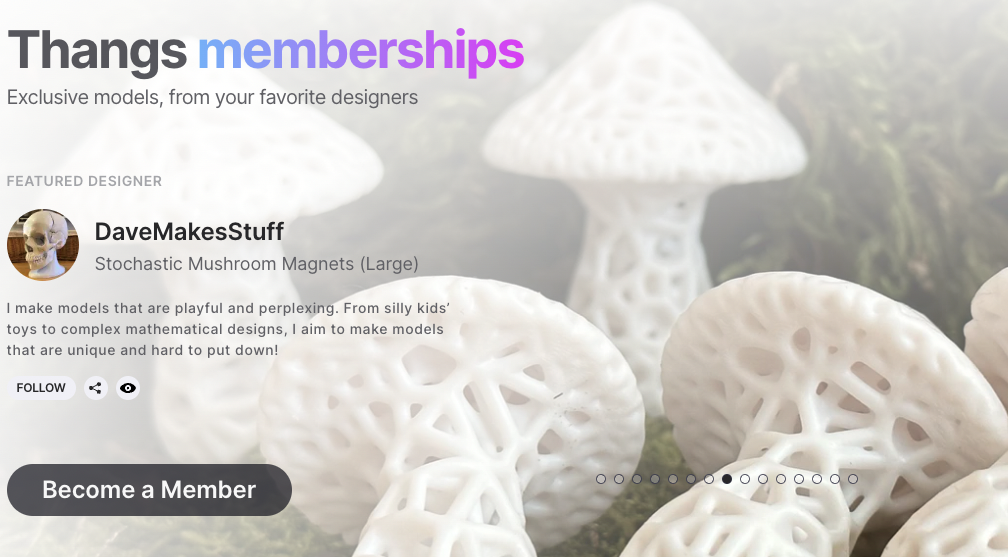

In an engaging discussion, DaveMakesStuff, a physiotherapist by profession and a 3D printing enthusiast by passion, shared how he ventured into the realm of 3D design and printing. He originally delved into this technology to create accessible, “un-branded” anatomical models for clinical and academic education, which are now used globally, particularly by non-profit organizations in developing countries. DaveMakesStuff, who found solace in 3D designing during the stressful COVID lockdowns, describes it as a meditative escape that allowed him to explore the world of beauty, silliness, and even technical mathematical designs. He also expressed his gratitude towards the generous sponsors like Onshape, nTopology, Snapmaker, Lulzbot, and Resins3D that facilitate his creative process, “And of course, Thangs is the ecosystem that holds it all together and makes it real!”

Explaining his preference for Thangs, he emphasized its reliable functionality and the inclusive ecosystem that it aims to create, fostering a space for everyone, from highly creative individuals to curious beginners. He also appreciated Thangs’ active presence on social media platforms and the energy they bring to the community. He expressed his excitement for Thangs Membership Programs, viewing it as a space where he can share his niche designs or, as he humorously calls them, his “blood, sweat, and tears” models. One project that holds special significance to him is a partnership with local daycares and preschools, where he tests his complex mathematical designs on a room full of four-year-olds. Observing how children interact with his 3D printed models offers invaluable feedback that assists him in his design iteration process, “If one of my designs is a hit with the four-year-olds, I know it’s going to be a hit on Thangs!”

Stephen Kelly, better known as The Light Speed, has been a consistent figure in the 3D printing community since 2017. Starting with a Flashforge Finder, and then moving to Prusa MK3, he now operates with Bambulab printers, Vorons, and RatRig V Core printers. Driven by his interest in learning, Kelly downloaded Fusion360 in 2019 and devoted an hour daily to mastering the software. Today, he offers his design skills via freelance projects, Thangs Memberships, and Patreon.

Kelly initially chose Thangs as his hosting platform due to their weekly design contests, which he viewed as a dependable avenue to monetize his creations. He found Thangs’ Memberships feature to be superior to Patreon, solving all the problems he previously encountered on the latter platform. He further lauded the Thangs team for their supportive and readily available assistance to the community. A project he recently worked on was a V6 engine model that doubles as a can cooler, a unique design he believes hasn’t been seen on the internet before. After months of dedication, he debuted the design on Thangs, and it has since grown into a series of four.

Convert STLs to Cash

In the world of 3D printing and design, the monetization of design platforms has largely remained untapped until a relatively recent surge.

Paul Powers, CEO of Physna, discussed their move to begin financial interactions on the search engine and file-sharing site Thangs. “This is the first time we’ve monetized Thangs at all,” said Powers. “We’ve never had any financial interactions; there’s been no payment gateway on the site right up until very recently.” Notably, the new release allows creators to earn money for their contributions to the site for the first time, shifting the dynamic of a largely free-exchange platform.

Instead of a system where creators might charge per model, Thangs’ monetization scheme is based on a subscription model, providing a more predictable income stream. As Powers explained, “If you have a good follower base, they’re not spending as much per model, but you’re making more money as a creator in a more sustainable way.”

The model seems to level the playing field, providing incentives for designers while maintaining affordability for followers. Part of the subscription even gives subscribers commercial rights, the ability to sell a model or 3D print something and then sell that 3D print. Physna’s approach also differentiates itself with a modest 8% commission from subscription earnings.

When asked about the revenue split on other platforms, Powers acknowledged, “Prusa Printables hasn’t come out with theirs. They take around 10%, according to their blog.” Powers was quick to note, however, the unique feature that Thangs offers – IP protection. “Because we crawl the web, if someone were to download your model, and then upload it for sale on another site, we can catch that,” he said.

Proactive protection against intellectual property theft is something that has been lacking in the industry, leading many designers to look for safer platforms to monetize their work. Powers stated, “The majority of the designers we talked to named this as the number one feature they cared about most.”

As for the revenue model, Powers likened it to Patreon, explaining, “When you subscribe, it’s very much like Patreon in the sense that you’re not subscribing to Patreon. You’re subscribing to that person whose stuff is on Patreon.”

However, it’s not just about monetizing, Powers sees the potential of further empowering creators in the 3D design space, perhaps even moving towards more advanced features, akin to a GitHub model. All in all, the goal is to make Thangs self-sustaining, allowing the platform to operate independently without relying heavily on venture capital.

The power of listening to the 3D printing community

“What we’ve done really well is listening to the community,” Powers states. Their growth rate is not just impressive, it’s remarkable, and according to Powers reached a million registered users more than twice as fast as any other company in the 3D sphere. This rapid uptake, with “very, very little marketing,” was driven mainly by the community. “We did that because we were listening to the community and reacting very quickly to their feedback, to their questions with their suggestions, and engaging with them.”

A standout aspect of Physna’s offering is its advanced geometric analysis technology, which Powers refers to as a major factor in its success. This technology unlocks opportunities for applications in the 3D space that other platforms can’t replicate. To further illustrate this, he compares it to the emergence of tools like Google and GitHub, emphasizing how they revolutionized the tech space. Similarly, Physna aims to transform the landscape of 3D technology, making it more accessible and influential in a world increasingly shifting towards AR/VR and 3D content.

On the subject of areas for improvement, Powers admits there is a need for clarity around some of the features on Thangs. He notes that “about 75% of the features and capabilities people were requesting,” already exist on the platform, but users weren’t aware of them. It’s a “discoverability issue,” he concludes, that needs to be addressed without making the site seem cluttered or overly complex.

AI and 3D Design

Discussing the intellectual property (IP) aspect of Thangs, Powers talks about Physna’s international patent for breaking down and analyzing 3D models, creating a new type of ‘technical primitive.’ It’s an innovation that he likens to binary code but in the physical world. There’s a hint at future patents, especially in relation to 2D to 3D model recognition and generative AI. However, Powers clarifies that they won’t be using user models for training or extracting data.

The fear of AI replacing designers is a concern Powers tackles head-on. He argues that Physna’s approach is not about replacing designers, but rather about empowering them with AI. Crucially, he envisions a future where AI doesn’t steal or average out people’s creations but enables individuals to express themselves in their unique styles. It’s a smart take on the role of AI, where it’s not just a tool for generating designs, but also for accentuating the individual creativity of the designers themselves.

Leveraging 3D Technology: Protection and Empowerment of Intellectual Property

Reflecting on the backdrop of Getty Images lawsuits against Stable Diffusion, Powers points out potential parallels in the 3D realm if people aren’t mindful. This represents a consequential chapter of the discourse around intellectual property rights.

He admits, “Yeah. I think that you could see something like that happen in 3D if people aren’t careful. And they, you know, morally or legally take advantage of people’s intellectual property.” This statement underpins his profound concern over the preservation of creative incentives and the promotion of innovation in the field of 3D designs.

3D designs have seen less innovation over the past 50 years than expected, he observes. Comparing our reality to the sci-fi utopia of Back to the Future, flying cars remain elusive despite the great strides in information technology. To him, it’s about catching up, breaking down software silos, and fostering collaboration. “If you get rid of the incentives for somebody to be creative, then you’re slowing down innovation,” he cautions.

Regarding the utilization of the Series B funding round of $56 million announced in July 2021, Powers reveals that the capital has been devoted to technological development and building out functionality. “So we’re very lucky to have the amount of capital that we have,” he says, radiating confidence about the future financial strength of the company.

Asked about a comparison to Yeggi, Powers clarifies that Thangs is much bigger, capable of advanced searches, and allows for a wider array of users. As the conversation wraps up, he expresses excitement about the future, with Thangs Memberships now open for anyone to be creator, “We would love to see as many people as possible make a living off of their work.”

His final words are a testament to the transformative power of 3D technology and its potential to reshape the creative landscape. The future of 3D tech lies in striking a balance – embracing the inevitable change it brings while also safeguarding intellectual property rights and in turn, fostering a fertile ground for innovation. The grand vision of the Physna CEO is not just about technology but also empowering the people who create with it.

Learn more about the leaders in the 3D printing industry in our Executive Interview Series:

Nadav Goshen, CEO of UltiMaker on Thingiverse, AI tools and a message to the 3D printing community

Alloy Enterprises CEO Ali Forsyth, metal additive manufacturing and disruption

Peter Hansford, CRO at Wayland Additive, solving a 20-year problem

Katie Snediker, CEO Jett3D, finding a profitable niche in 3D printing

What does the future of 3D printing hold?

What engineering challenges must be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Physna’s ability to searchable catalog of 3D models and parts. Image via Physna