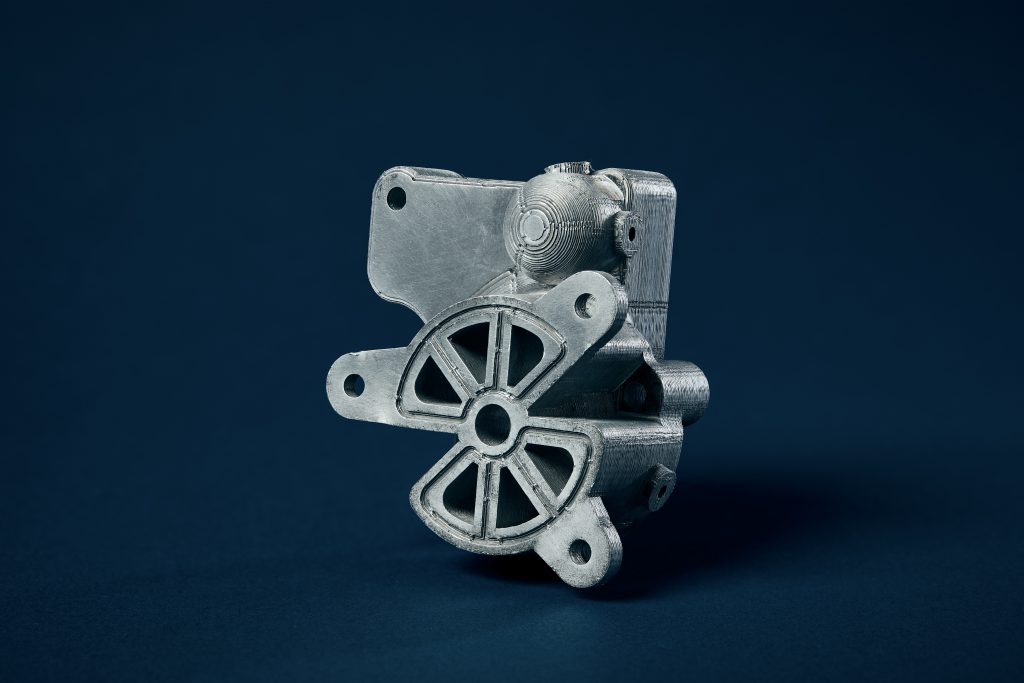

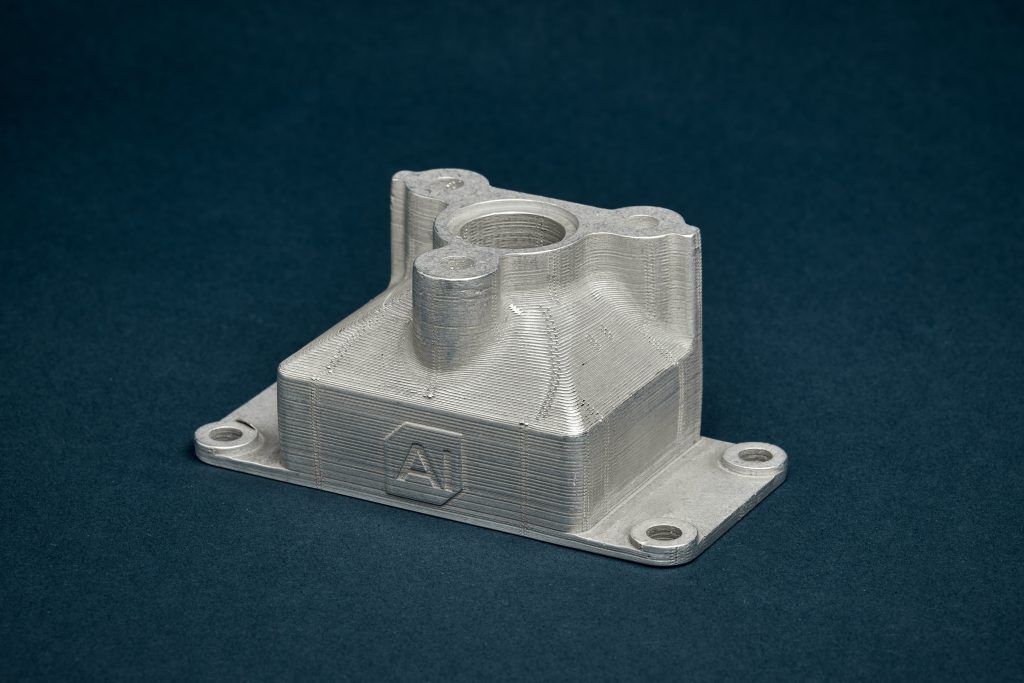

Alloy Enterprises, a forward-thinking manufacturing startup based in Massachusetts, is redefining the paradigm of metal 3D printing, offering a high-speed, cost-effective approach to lightweight components.

I spoke to the company’s co-founder and CEO, Ali Forsyth, to learn more about a novel additive manufacturing technique that draws inspiration from laminated object manufacturing, a precursor to 3D printing. “We’ve developed a new manufacturing method to make lightweight aluminum components… but we’re actually not laminating. We’re bonding metal to metal,” Forsyth explained.

Alloy Enterprises‘ approach involves a specifically designed aluminum alloy, which they fabricate into a sheet. This sheet gets rolled up and fed into the first of two machines, where it is cut according to the designated part’s perimeter and then dispensed into the second machine. This process provides a significant speed advantage over Laser Power Bed Fusion (LBPF) as it does not need to move point by point through the entire area, just the perimeter of the part.

Forsyth explains the second step of the process, “We get something onto the surface… that provides an inhibition layer…acting like a mold release.” The sheets are then stacked up, heated under controlled conditions, and bonded together into a block. This method allows for creating complex shapes while maintaining high speed and efficiency. The result is a 6061 aluminum alloy that is fully dense, and similar in composition to the common aluminum alloy widely used in industry.

One key aspect of this novel method lies in its potential for lower costs and increased throughput. Forsyth highlighted, “The whole thing’s been designed… from the get-go, around cost reduction and throughput.” Alloy Enterprises aims to compete with traditional casting for series production and use parts, eyeing economies of scale inherent to their novel process.

The ingenuity of Alloy Enterprises’ fabrication method is attracting considerable interest within the industry. Forsyth points out that the layered manufacturing approach has garnered attention because it can offer a high volume of series production and use parts, effectively competing with casting 10 to 1000 parts per year.

This innovation represents an important departure from other metal additive manufacturing methods, where costs, particularly for metal, can quickly escalate. “We were able to produce a significant cost reduction by moving away from powder… you can move a lot more metal through a machine with sheets than you can with powder or wire,” Forsyth emphasized. This approach underscores a new era of manufacturing where economies of scale, speed, and reductions in touch time are the principal focus.

Founded in 2020, Alloy Enterprises has evolved rapidly and is already in production. This quick turnaround is attributed to a team of seasoned professionals who have previously developed other additive processes. Forsyth, an experienced engineer who previously led an engineering team at Desktop Metal, values the lessons learned from her previous tech startups. She emphasized the importance of “simplicity, like elegance and simplicity of design,” for a field that can quickly get complicated.

Targeting a $75 billion industry, applications of aluminum additive

Alloy Enterprises owns all the Intellectual Property (IP) surrounding their technology and is keen to uphold Massachusetts’ reputation as an incubator for cutting-edge startups. Forsyth’s co-founder and CTO, Nick Mykulowycz, had the initial idea and between them, “We cooked this up in his basement, then my carriage house after that.” Previously working for Desktop Metal, Mykulowycz is named an inventor on several other patents developed over four years with the company.

The new technology developed by Alloy Enterprises promises to reshape our understanding of aluminum fabrication, painting a future of high-speed, cost-effective manufacturing that could disrupt the $75 billion global aluminum casting industry.

The company’s focus is on aluminum, a material Forsyth described as “infinitely recyclable” and crucial for the electrification of various industries. This focus on aluminum aligns Alloy Enterprises with the global transition towards a more sustainable, electric-powered future.

One key application area is thermal applications – cold plates, heat exchangers, and battery enclosures where active cooling is required. The superior thermal conductivity of their 6061 aluminum—approximately 70% higher than cast aluminum – makes it ideal for these applications.

When asked how Alloy Enterprises has achieved such impressive cost and time reductions in manufacturing, Forsyth highlighted the benefits of leveraging the high-volume aluminum rolling industry and automation. By cutting just the perimeter of the part with a laser, the process becomes substantially faster. Furthermore, the company has worked hard to reduce touch time wherever possible in the manufacturing process, which has also significantly driven down costs.

Despite being in operation for three years, Alloy Enterprises recently secured $26 million in funding. The Series A round was led by Piva Capital with new investors Unless, Flybridge Capital, MassMutual Catalyst Fund, Robert Downey Jr.’s Footprint Coalition, and existing investors Congruent Ventures and Riot Ventures participating. Alloy Enterprises has so far raised $37 million in total.

The investment will allow the company to scale, build two of its automated fab cells at its Burlington headquarters, and expand the applications it can provide for its customers.

Forsyth explained that the primary competition for Alloy Enterprises is the traditional aluminum casting industry. With its advanced technology and superior material properties, the company can produce more complex geometries at a faster pace and at a lower cost than traditional casting methods. Alloy Enterprises effectively merges the benefits of 3D printing with the cost-effectiveness and scale of traditional casting.

Future plans for Alloy Enterprises

Looking to the future, Alloy Enterprises has plans that both sustain and amplify its current business model. Forsyth explained that the company aims to continue selling components to its customers and building out its own fabrication facilities that are centered around its groundbreaking technology.

Forsyth provided insight into Alloy Enterprises’ plans for the next five to ten years, stating that their immediate focus lies in constructing their first two cells and demonstrating the scalability of their technology. “We’re already producing and selling parts to customers. But being able to do that at scale here and demonstrate the technology at scale is an important next step for the company,” Forsyth said.

From there, the first fabrication plant will be developed. Forsyth also hinted at a potential decentralized fabrication strategy, whereby the company could co-locate with the suppliers of the aluminum material or even with the customers themselves.

Addressing potential challenges in scaling operations, Forsyth showed confidence in the company’s ability to overcome them, drawing from the success and progress Alloy Enterprises has achieved thus far in challenging market and pandemic conditions.

Asked about the possibility of an Initial Public Offering (IPO), Forsyth chose not to disclose any plans. The conversation then moved to the core team that has been instrumental in Alloy Enterprises’ journey. The team boasts skilled individuals in engineering and production teams, as well as applications. Forsyth named a few key contributors, including Jim Golden, their recently onboarded VP of Sales, and Dr. Kevin Simon, the company’s Director of Engineering, along with lead metallurgist Dr. Alan Lai.

Forsyth also highlighted the importance of investors to the company’s journey, expressing gratitude for the partners they’ve brought on board, especially those who understand the intricacies of “hard tech”, manufacturing, and the industrial space.

Touching on the industry’s future, Forsyth underlined the growing trend of electrification in transportation and the role aluminum would play in this transformation. “The amount of aluminum that’s in passenger vehicles was up 550% over the last 50 years,” Forsyth said. With the high strength-to-weight ratio of aluminum, it’s expected to be a key player in the electrification journey of not just passenger vehicles but heavy-duty trucks and aircraft as well.

Finally, Forsyth shared that Alloy Enterprises will be exhibiting at Formnext later this year, where attendees will have the chance to get a firsthand look at their technology and the components they produce.

What does the future of 3D printing hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays. Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the team at Alloy Enterprises. Photo via Alloy Enterprises.