SLM Solutions Group, a German manufacturer of metal 3D printers, is to support the German Institute for Standardization (DIN), who has founded the Additive Manufacturing Steering Committee in the DIN Standards Committee Technology of Materials.

Dr. Dieter Schwarze, Director of Scientific and Technology Research at SLM Solutions, is expected to steer the committee as Deputy Director, with the aim of increasing standardization work in additive manufacturing. “SLM Solutions places great value on uniform norms and standards,” said Dr. Schwarze.

“Our SLM machines are extremely robust and stable. Together with our technological experience, this makes us the right partner to help shape the future of additive manufacturing in series production, from greater occupational safety and cost savings to improved component quality and safety.”

Addressing the hurdles of metal manufacturing

Previously, Jim Fendrick, Senior VP of SLM Solutions NA, told 3D Printing Industry, “Metal additive manufacturing still faces many hurdles. Qualification certainly creates a bottle-neck in the industry, as there are still no clear standards across the board and several organizations are working on such standards today. But at the moment, it still creates a barrier for many.”

The Additive Manufacturing Steering Committee was established earlier this year to accelerate the commercial viability of metal 3D printing. This objective takes into account economic feasibility, technological relevancy, scientific insights, legal developments, financial conditions, and the harmonization of technical rules across Europe and worldwide for such additive manufacturing processes.

In addition, the committee is cooperating with other standards committees within DIN to analyze the mechanical properties of metallic additive manufacturing materials for the aerospace sector.

Standards for aerospace metal 3D printing

Standards are vital within metal-based 3D printing as they enable manufacturers to innovate materials, processes, and product innovation, particularly in advanced industries such as aerospace.

Earlier this year, SAE International issued four new standards relating to laser powder bed fusion (LPBF) powered additive manufacturing. The LPBF documents are designed to support the certification of metal 3D printed parts for use in aircraft and space exploration vehicles, and are officially supported by the Federal Aviation Administration (FAA).

Following this, America Makes, and its partner the American National Standards Institute (ANSI) published the Standardization Roadmap for Additive Manufacturing (Version 2.0) which lists 93 “gaps” in appropriate standards and specifications for 3D printing and its related processes.

For regular 3D printing news updates subscribe to the 3D Printing Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

Looking for new talent or seeking a career change? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

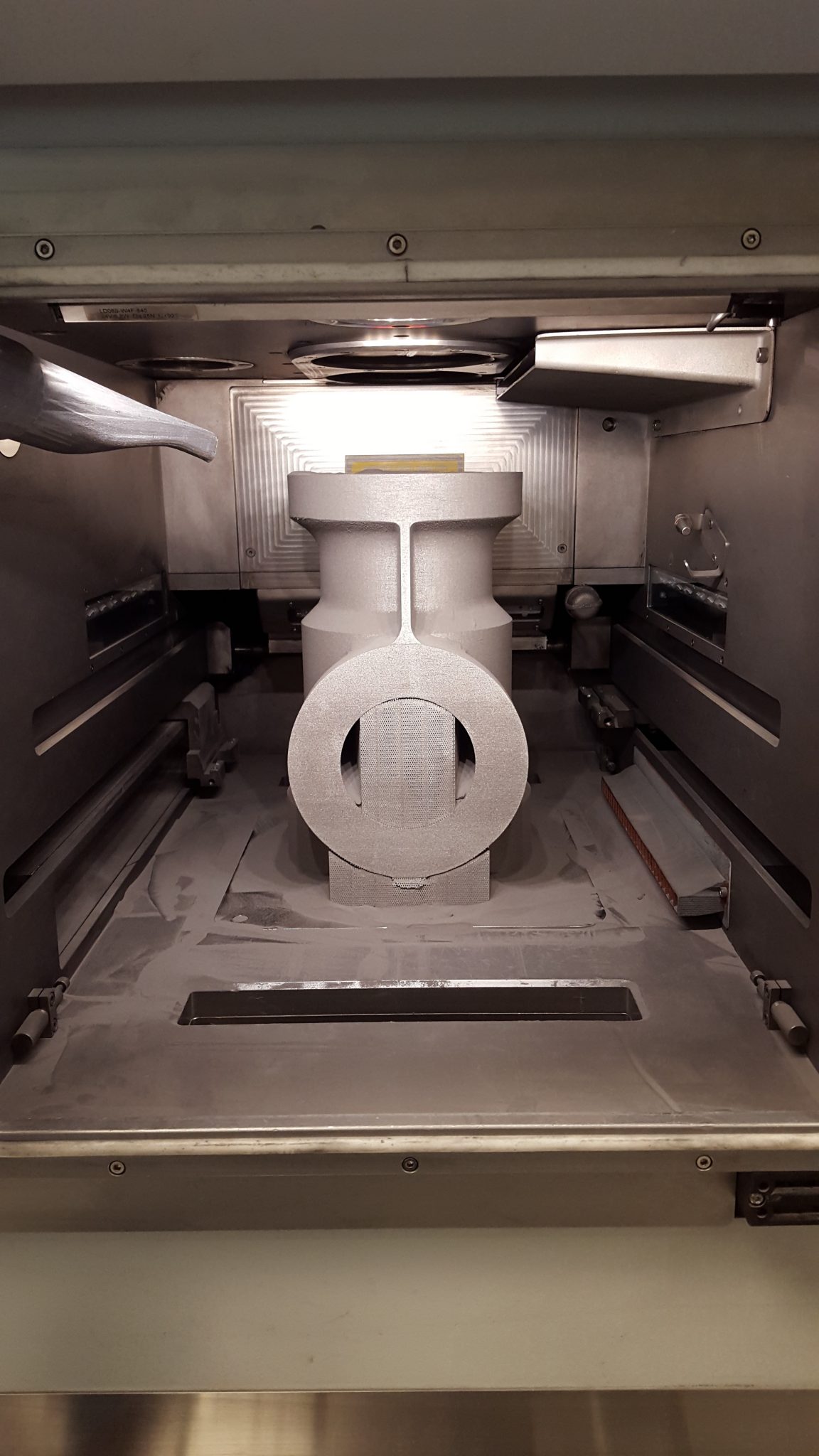

Featured image shows a metal tire mold segment 3D printed by SLM Solutions. Photo via SLM Solutions.