Its time for the first Sliced 3D printing digest of the week, featuring: 3D printed food, 3D scanning tailors, BAE Systems engineering academy, the Henry Ford Hospital, delays to the Glowforge and a new multi-tool printer/CNC/scanner from FABtotum.

The newest multi-tool on the block

Italian 3D printing and CNC milling company FABtotum recently released an upgrade to their Personal Fabricator multi-tool printers. The CORE model is faster that FABtotum’s first printer from 2014, and adds to it a Web Interface called FABUI which means it works as a standalone machine. It keeps the same 3 interchangeable print heads as the first Fabricator, capable of 3D printing, scanning and milling, and all the parts are truly backwards compatible for less hassle to current owners looking to upgrade.

Precision fitted suits come from 3D scanners in Hong Kong

A 3D scanning booth has popped up in Hong Kong based tailors GAY GIANO. Eliminating the need for a tape-measure and cutting down on time, this body scanner records over 100 measurements of a person’s body in under 30 seconds, which is around 6 times the amount taken in a typical fitting and a fraction of the time. Having this image of a customer also means that designs can be drawn up digitally on the spot.

Engineers wanted in the UK

According to the Financial Times newspaper, “Engineering companies need to find 182,000 people every year until 2022 to cover retirements and expected growth. There is already a 55,000 deficit and the Brexit vote could make it harder to attract skilled staff from overseas.”

To address this skills shortage BAE Systems, headquartered in the UK in London and Farnborough has invested £15.6m in the future of Britain’s engineers. A new aerospace training academy from the manufacturer will prepare 200 new apprentices per year with the skills necessary to build aircraft. In coming years the academy’s success will depend upon it’s ability to keep with the times and contain to explore new technologies. Preparing the Smart Factories of the future, alongside an open access to external suppliers is a promising boost to the UK’s additive manufacturing sector.

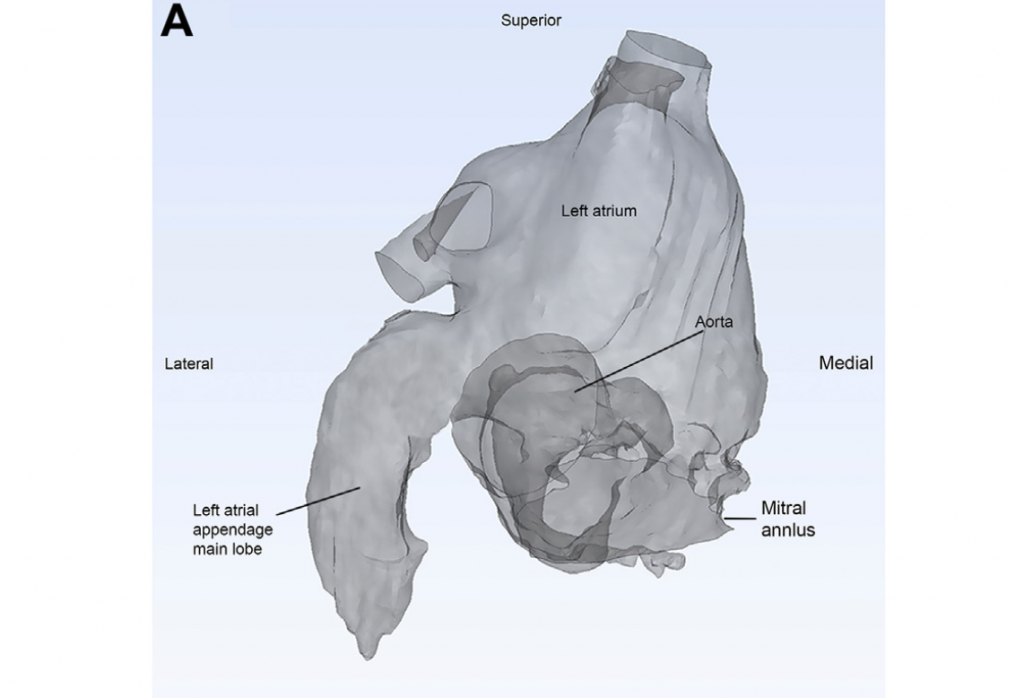

Doctors there in a heart-beat thanks to 3D imaging

A study from the Henry Ford Hospital in Detroit has discovered a way to use 3D imaging to solve one of the world’s most common heart-irregularities. Atrial fibrillation is found in people as an abnormally high pulse rate, dizziness, shortness of breath and is a major cause of strokes. It can be solved by a surgical procedure, but 2D imaging does not have a water-tight success rate. In a paper for the American College of Cardiology Foundation, cardiologist Dee Dee Wang shares how 3D imaging a heart for a surgical procedure eradicates complications associated with 2D imaging, due to, ‘”fewer last-minute decisions, less contrast usage, and less catheter movement inside the heart”.

3D printing flopped? Certainly not!

Autodesk Chief Technology Officer Jeff Kowalski has recently commented on the “3D printing hype bubble,” in a speech that reportedly highlights a gap between the possibility of the technology and the technical capabilities of hardware and users. Despite the phrasing of some headlines covering his recent Q&A, what Kowalski was really saying is that Autodesk are being shrewd with how to place themselves in the 3D printing market, and rightly so, as it would be foolish for the software company not to keep exploring different areas.

The CTO said that Autodesk are looking for areas “where [their software is] adding something really different, sticky and valuable in our customers’ workflows.”

Another year in the waiting for Glowforge’s 3D laser printer

In 2015, Glowforge made history as the biggest 30-day crowdfunding campaign to date, earning a total of $27,907,995 from backers eager to get their hands on a desktop machine that can cut and engrave a myriad of materials. This year, they promised backers that the printer would be with them by December, but in an update from founder Dan Shapiro at the beginning of this month, Glowforge have announced a new ETA of March – August 2017. The update also proposes to add a 3D printer head to the Glowforge to extend its capabilities.

Nufood present a 3D printer that “extends modernist cuisine techniques to create juicy flavour bursts”

If you’re getting a little hungry waiting for Glowforge and still have an appetite for Kickstarter then UK based 3D food printing enterprise Nufood are raising money on the platform at the moment. Nufood are offering 3D printed food experiences at several European locations next year, but international events are also a possibility according to the company’s Kickstarter page.

Featured image shows Sliced logo on a laser engraved leather mousepad made by the Glowforge printer. Original photo: Glowforge on Facebook