Skyrora, an Edinburgh-based private rocket manufacturer, has developed what it claims to be the largest hybrid 3D printer in Europe.

Poised to start production in Q2 2022, the firm’s upcoming Skyprint 2 3D printer will be used to manufacture large-format rocket engine parts up to 2.3m in length for Skyrora’s satellite launch vehicles. The machine is built on the previously developed Skyprint 1 and will feature both metal 3D printing and traditional CNC milling functionality in the same workspace.

According to Skyrora, the Skyprint 2 will drastically reduce process complexity, while slashing production costs and printing times by around 30% when compared to other metal 3D printers.

Volodymyr Levykin, Skyrora’s founder and CEO, said, “Skyprint 2 reinforces our ambitions to not only be the first company to launch from UK soil, but also to do so in the most sustainable way possible. By taking greater control of the design and manufacturing process of our parts using our custom-built industry-leading 3D printing technology, we are taking another crucial step closer to offering a significant space service from our own soil.”

Advancing UK space flight with Skyrora

Founded back in 2017, Skyrora aims to be the leading space launch company in the UK. Primarily targeting the growing small satellite market, the firm uses a combination of additive and conventional manufacturing to produce its own rockets. The company now has more than 150 employees across Europe and hopes to be the first to launch from a UK spaceport by 2022.

Back in 2019, Skyrora announced the opening of a new engine test facility in Scotland. The facility has since been used to complete burn and gimbal tests for its rockets.

Earlier this year, the firm also successfully completed trials of the third stage of its Skyrora XL rocket. The launch vehicle is designed to be able to refire its engines around 15 times once in orbit. It will be used to complete tasks such as acting as a space tug or de-orbiting defunct satellites.

More recently in October 2021, Skyrora announced a multi-launch agreement with spaceport SaxaVord, The deal will enable the company to complete 16 launches a year by 2030.

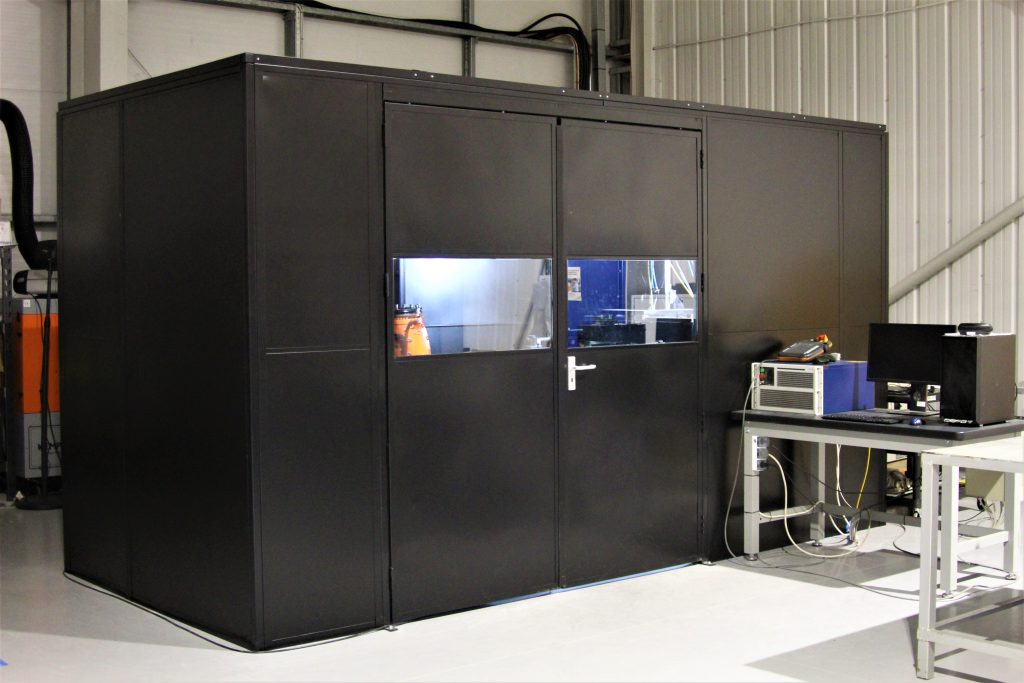

The Skyprint 2 3D printer

The Skyprint 2 will operate on Skyrora’s Directed Energy Deposition (DED) 3D printing process, a form of additive manufacturing that leverages high-power laser beams to melt metal powder as it’s deposited out of a nozzle. The approach is known for its excellent material efficiency, ability to produce near-net-shape components, and repair parts by simply printing additional layers on.

Using the system’s CNC capabilities, Skyrora will be able to machine its printed parts to achieve the final finished geometries. The firm will also be able to machine parts that were not originally printed.

According to Skyrora, Skyprint 2 will be compatible with Inconel, a nickel-based superalloy known for its high strength, excellent corrosion resistance, and stability at high temperatures. The metal is one of the go-to options for high-stress, high-temperature parts in industries such as aerospace, and happens to comprise the bulk of Skyrora’s rocket engine components.

The traditional manufacturing of Inconel engine parts can take around ten weeks from design to delivery, and that’s without counting any quality modifications or iterations. Using Skyprint 2, Skyrora expects to be able to 3D print its own ready-to-use Inconel parts in just two weeks. The system will also enable the firm to conduct rapid design iterations as and when needed, all without the associated time and cost burdens.

Levykin adds, “Creating this cost- and time-effective solution encapsulates the innovation and talent that resides at the heart of the UK space industry. As an asset, Skyprint 2 is a real game-changer – it will transform Skyrora’s operations and expand the limits of what is possible when it comes to space engineering in general.”

With advancements in additive manufacturing technology, the 3D printing of rocket engine components is becoming more common. In October, private US aerospace firm Launcher hit another milestone in the testing of its 3D printed E-2 rocket engine at NASA’s Stennis Space Center. The company also purchased a second Sapphire 3D printing system from OEM Velo3D, which it will use to 3D print titanium orbiter pressure vessels for the engine.

Elsewhere, California-based aerospace firm Rocket Lab was recently awarded $24.35 million by the U.S. Space Force to fund the R&D of its next-generation Neutron launch vehicle. The rocket is powered by the company’s 3D printed Rutherford engine and is capable of carrying up to 300 kilograms into low earth orbit.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a rendering of Skyprint 2. Image via Skyrora.