Indian space start-up Skyroot Aerospace has raised $51 million towards the development of its 3D printed cryogenic engine-powered rockets.

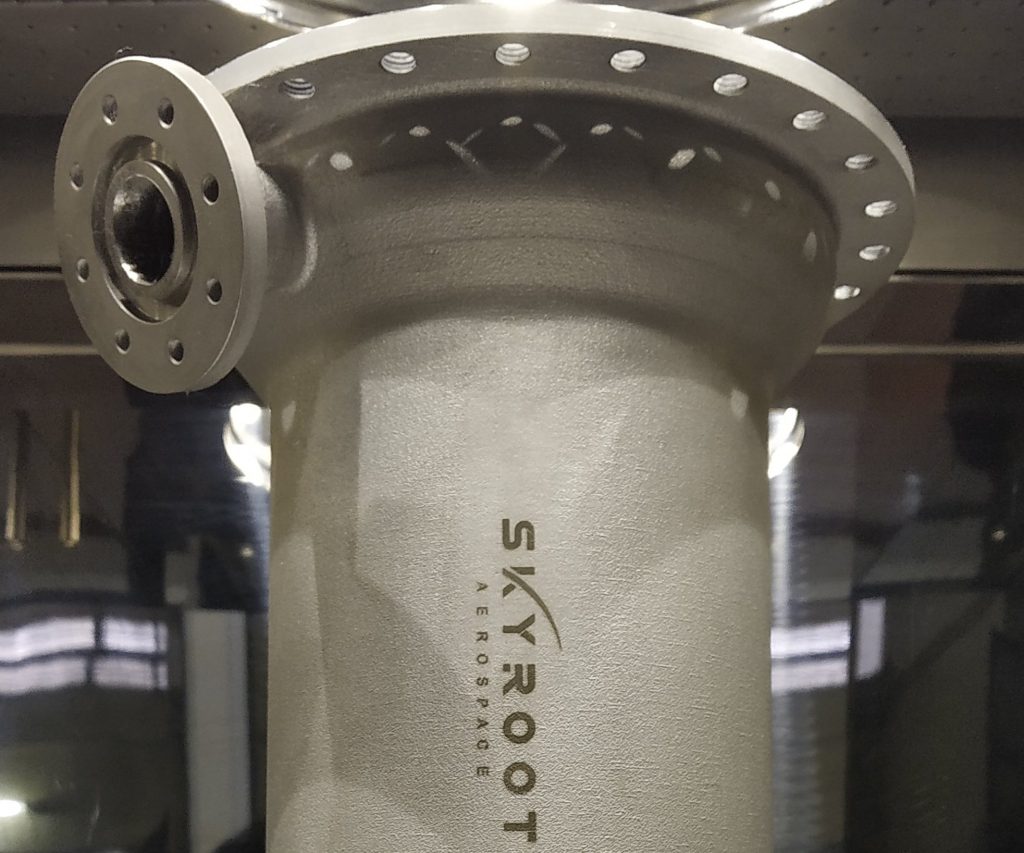

Capable of carrying up to 815-kilos into Low Earth Orbit (LEO), Skyroot Aerospace’s Vikram launch vehicles are propelled by the Dhawan-1, an engine 3D printed from a superalloy, in a way that reduces its production time by 95%. Having secured Series B backing via a round led by Singaporian investor GIC, the firm now has the cash to fund its initial launch tests, and establish its own satellite launch service.

“This round puts us on a trajectory of hyper-growth by funding all of our initial developmental launches, and enables building infrastructure to meet high launch cadence required by our satellite customers,” said Pawan Kumar Chandana, CEO of Skyroot Aerospace. “Our objective is to establish ourselves as a provider of best-in-class rocket launch services and the go-to destination for affordable and reliable small satellite launches.”

“We are proud to welcome one of the world’s leading institutional investors as a long-term partner in our mission to ‘Open Space for All’”

Democratizing space exploration

Skyroot Aerospace was set up in 2018 with the aim of making Earth-to-space transportation less expensive. The company sees doing so as vital to broadening access to space exploration from just a handful of governments and firms to wider research groups, and through “pushing the boundaries of today’s technology,” it says it’s possible to “open space for all.”

Primarily, Skyroot Aerospace’s efforts to achieve this have revolved around its Vikram launch vehicles. Named after Dr. Vikram Sarabhai, founder of the Indian Space Program, the modular rockets are built specifically to cater for the satellite launch market.

Numbered Vikram I to III, the firm’s rockets are each capable launching 480-815 kilograms into LEO, thanks to their fully-3D printed cryogenic engine. Unveiled in late-2020, Skyroot Aerospace’s propulsion system is cryogenic in that it’s fuelled by a liquid natural gas cryo-propellant, and it’s reported to have been created entirely from high-strength carbon fiber using powder bed fusion (PBF).

Designed to propel the upper-stage of the firm’s rockets, the engine is said to be capable of multiple restarts, potentially enabling it to drop satellites into several orbits on a single mission. With Skyroot Aerospace estimating that 20,000 small satellites will be launched to LEO over the coming decade, it now aims to address this market itself via its own launch service, with the Vikram at the heart of it.

Scaling up for a commercial launch

Said to be the largest funding round of any Indian space firm to date, Skyroot Aerospace’s backing provides it with the cash needed to go from rocket testing to establishing commercial launch capabilities. The funding round’s main backer, GIC, doesn’t list its full portfolio in its reports, but it positions itself as an investor in tech firms, making it a useful long-term backer for a business still building its offering.

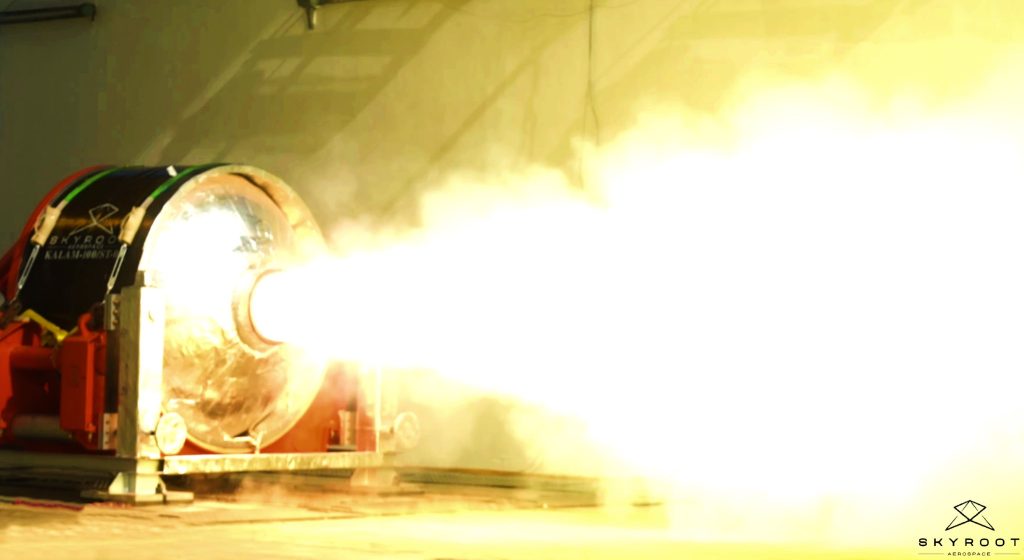

That said, Skyroot Aerospace continues to make progress in the R&D of its Vikram rockets, with the Vikram-I successfully passing third-stage testing in May 2022. During the test, which was carried out at the facilities of one of the company’s other investors, Solar Industries India, the launch vehicle is reported to have generated a peak vacuum thrust of 100 kN and achieved a burn time of around 108 seconds.

Moving forwards, using its newly-raised capital, Skyroot Aerospace expects to be able to complete initial flight testing, in addition to expanding its engineering team and infrastructure in preparation for the launch of its services next year.

“We have validated all three propulsion technologies in our Vikram space launch vehicles, and completed a full duration test of one of our rocket stages in May ’22,” added Skyroot COO Naga Bharath Daka. “We are also planning a demonstrator launch to space this year. This round will help us get to full-fledged commercial satellite launch scale within a year from now. We have started booking payload slots for our upcoming launches.”

3D printing as a spaceflight enabler

Cryogenic rocket propulsion systems i.e. those fuelled by gasses that have been liquified and stored at cold temperatures, are hardly new in the world of spaceflight. In fact, Pratt & Whitney’s RL10 was first flown in 1963, but it’s still the most-used upper-stage engine in the US, with Aerojet Rocketdyne now contracted to build it.

As you’d expect with an engine developed 59 years ago, its latest manufacturing custodian continually iterates on its design with the aim of improving its performance. As long ago as 2017, the firm hot-fire tested a 3D printed RL10 thrust chamber, and it has since received an order for 116 part-3D printed RL10C-X engines from United Launch Alliance.

Elsewhere in the 3D printing industry, the technology has also been deployed extensively in the creation of launch-ready rocket propulsion systems. Rocket Lab’s 3D printed Rutherford engine, for example, continues to be used to propel the Electron into LEO, a rocket that’s now completed 29 launches and fired 149 satellites into orbit.

More recently, X-Bow Systems has tested its Bolt rocket, as part of a mission that saw it carry a test payload for Los Alamos National Lab. The Bolt is powered by Ballesta 3D printed rocket engines, which are fuelled by propellant grains with flexible geometries that can be tailored to meet application-specific requirements.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a concept image of a Skyroot Aerospace Vikram rocket. Image via Skyroot Aerospace.