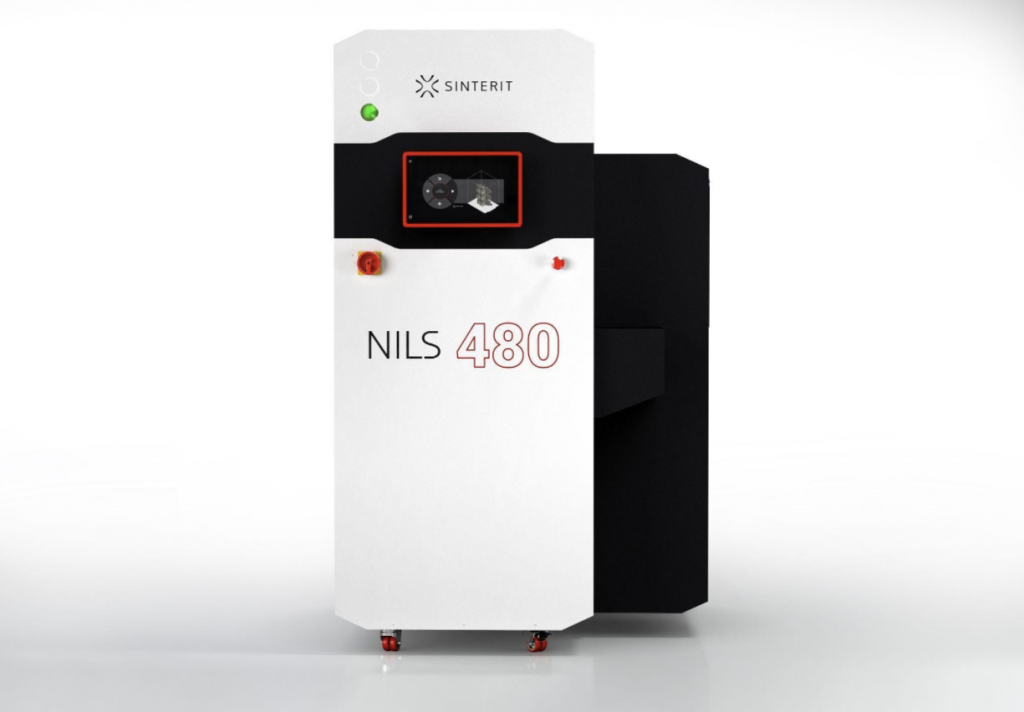

Polish SLS 3D printer manufacturer Sinterit has announced its entry into the industrial additive manufacturing market with the unveiling of its New Industrial Laser Sintering (NILS) 480 system.

Compared to Sinterit’s desktop predecessors, the NILS 480 features an upgraded build volume and print speed, allowing it to serve as an accessible option for those seeking to enter series production. Given SLS technology’s inherent flexibility, the firm also sees its latest printer as a challenge to conventional industrial machines, and ahead of launch, it says that adopters could “achieve a ROI in just 40 days.”

“Having sold over 1,000 compact systems worldwide, we have decided to reinvent the industrial-grade printer,” said Maxime Polesello, CEO of Sinterit. “Starting with the compact Lisa raised the bar for us. Our goal was always to provide the highest SLS quality, but also to make this technology widely-available. With an attainable price in mind, NILS 480 draws from this experience.”

Sinterit’s SLS expertise

Based in Krakow, Poland, Sinterit has spent the last seven years establishing itself as a manufacturer of capable-yet-accessible desktop SLS 3D printers. In that time, the company has launched its Lisa and Lisa PRO machines, which have found applications ranging from medical masks to firefighting gear, cementing their place as cost-effective prototyping and low-to-medium-volume production tools.

More recently, Sinterit has sought to broaden its portfolio, with the aim of developing an ‘all-in-one solution’ that better addresses the needs of its growing client base. One way in which the firm has sought to achieve this is with hardware such as its Powder Handling Station. Launched last year, the new workspace is designed to allow users to rapidly recover powder, and house Sinterit’s entire add-on range.

The company has also expanded its powder offering, providing Lisa adopters with enhanced prototyping capabilities, and upgraded its Studio software so that users can manage their full end-to-end workflows, but with the NILS 480, it’s now taking accessible SLS to a new level, with the bold aim of addressing high-throughput clients like never before.

SLS on an industrial-scale

According to Sinterit, the NILS 480 is designed to act as a small-run manufacturer’s “pass to the industrial 3D printing world,” allowing them to produce higher volumes of small parts or larger single-unit models. In practise, the system enables users to achieve this via its 200 x 200 x 330 mm build volume, which is significantly bigger and more capable than Sinterit’s previous largest 150 x 200 x 260 mm Lisa PRO.

Likewise, although the firm hasn’t released the exact specifications of the NILS 480 yet, it says that the machine features an “industrial-grade build speed.” As a result, the system has potential prototyping, industrial and end-use manufacturing applications, and when deployed at top speed, it’s said to be capable of printing an entire bed of parts in a single day.

Much like Sinterit’s Lisa portfolio, the NILS 480 is also built with cost-efficacy in mind, and its smart powder distribution and continuous printing solution, enable the high-throughput 3D printing of components using the least material possible, and it’s said to feature “powder waste specificity” capabilities too, although little is known about these thus far.

Elsewhere, in terms of accessibility, Sinterit has stuck to its principles, building its new machine in a way that doesn’t require specialized, trained operators to use. In fact, the firm says that the NILS 480’s automation makes it “easier and faster to operate” than its current Lisa machines, and its upcoming 3D printer could therefore trigger an industrial “revolution,” that serves as a “game-changer” for its clients.

When will we know more?

So far, Sinterit has remained tight-lipped about the NILS 480’s exact specifications, but it has provided some minor insights into the machine’s price and compatibility potential. For instance, the firm has stated that the system’s material range will cover the “majority of key industry needs,” and given its substantial existing powder offering, this should allow it to address a variety of applications from the off.

When it comes to price, the company has also commented that most industrial-grade SLS 3D printers cost north of €100,000, and “few are priced between €60,000 and €100,000.” While stopping short of confirming the NILS 480’s pricing information ahead of launch, Sinterit has added that once unveiled, it will “open a new pricing chapter that makes industrial printers more accessible.”

At present, the company is planning to begin shipping its new industrial-grade offering in 2022, but those interested can find out more about the machine via a dedicated webinar on September 15, 2021. In the meantime, manufacturers seeking to begin low-to-medium runs of customizable 3D printed parts, can order Sinterit’s more form factor-friendly Lisa and Lisa PRO machines now.

Hosted by Polesello, alongside the firm’s heads of R&D, Sales and International Marketing, Michał Grzymała-Moszczyński, Tim Sheehan and Dominik Stasiak, the online presentation will see the NILS 480’s price, speed and waste-saving specifications confirmed. Interested parties can sign up to attend via the company’s dedicated event page here.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Sinterit’s upcoming industrial NILS 480 3D printer. Image via Sinterit.