Software provider Simplify3D has announced the release of version 5.0 of its paid slicing software.

According to the company, this software boasts “a next-generation slicing engine, integrated print optimizations, and feature-packed user interfaces for improved efficiency and intuitive operation.” A simplified user interface is prominent, featuring built-in toolbars, re-configurable keyboard shortcuts, sophisticated zoom and rotation controls, 3D mouse support, supporting Wi-Fi and Ethernet connections for remote printing, and more.

“This ground-up approach allowed us to achieve major software breakthroughs and establish a cutting-edge foundation for the future,” said Clayton Webster, CEO of Simplify3D.

Features of Simplify3D version 5.0

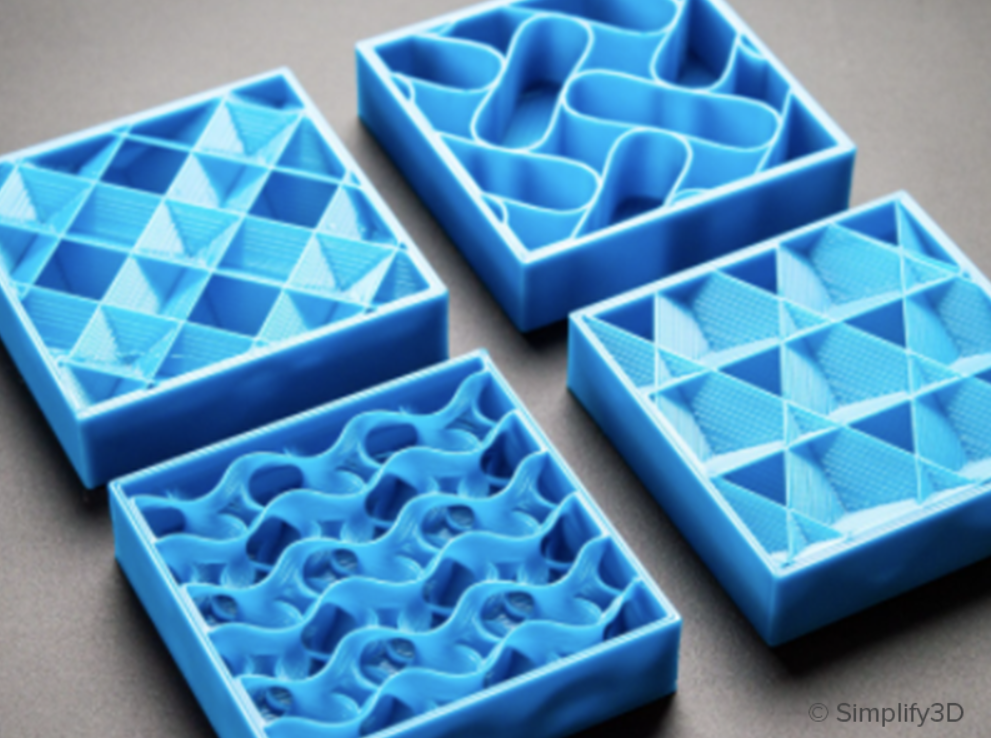

The software dynamically enhances layer height based on the model topology to achieve the optimal balance of quality and speed. Added lateral strength is achieved through the use of new 3D infill patterns that morph throughout the print, resulting in strong internal structures.

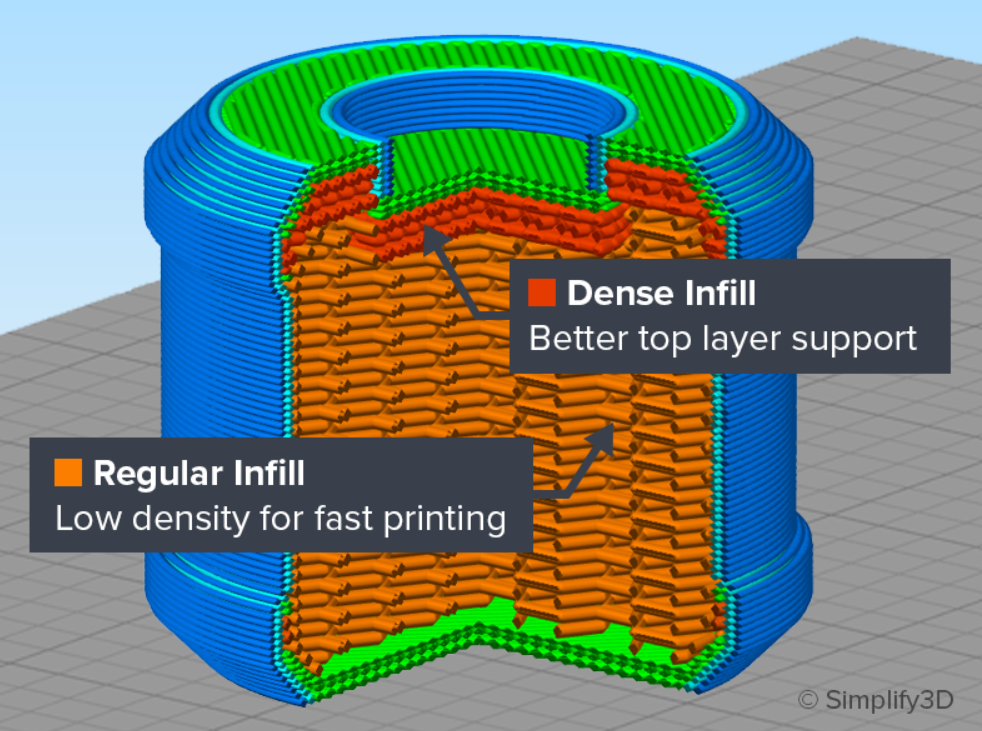

Surface defects are eliminated by automatically adjusting the start points for each layer so that the seam is obscured from view. Version 5.0 dynamically increases infill density near the top of the part for better top surfaces and less material usage.

The new WiFi and Ethernet connectivity options in Version 5.0 allow the user to monitor and control the 3D printer from a distance. It integrates seamlessly with widely known network-capable brands such as FlashForge, Ultimaker, MakerBot, Dremel, and Qidi.

Accurate Time Estimates enable the development of new algorithms that provide highly accurate time predictions with fine-tuneable parameters. New Coloring Modes offer enhanced ways to visualize and validate the printing process by providing new layer height and flow rate coloring modes. Detailed Preview Statistics examine tabulated data for each feature type, tool, and process, including the exact time and material usage.

“We redesigned every major system in the software to ensure it was optimized and ready to deliver the most important capabilities for our customers,” added the CEO of Simplify3D.

Enhancing additive manufacturing with 3D software

Recently, US-based software company Synopsys announced the release of Simpleware U-2022.12 3D image processing software. The newest Simpleware software release includes multiple novel features and enhancements. These include the Simpleware AS Ortho/CMF module’s new craniomaxillofacial (CMF) CT tool, a smart paint tool, an automatic option for 3D printing connectors, and additional materials analysis.

Furthermore, Mango 3D, a 3D printing software developer, released an update to its Lychee print preparation program, which makes it compatible with Fused Filament Fabrication (FFF). Lychee, which was previously a resin 3D printing slicer, now allows users to prepare files for production with both this technology and FFF on the same platform. Mango 3D’s expanded software, which was released as a public beta, effectively sees it go toe-to-toe with Prusa and Ultimaker, the developers of the PrusaSlicer and Cura slicers, respectively.

Follow this link for all the Formnext 2022 news.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Feature image shows Automated Seam Hiding. Image via Simplify3D.