Montreal-based software firm Shapeshift 3D has partnered with sports goods manufacturer CCM to automate the custom-fitting of CCM’s 3D printed hockey helmet liner.

While the liner is to be made available to the public in standard sizes, elite athletes have already been able to get theirs custom-fitted for the 2021 National Hockey League (NHL) season.

According to the partners, the agreement sees CCM become the manufacturer of the world’s first commercially available custom-fitted 3D printed hockey helmet liner.

“We are proud to partner with a hallmark brand so deeply committed to improving the safety and performance of those who practice our national sport,” said Jonathan Borduas, CEO of Shapeshift 3D. “We applaud the commitment to pushing the boundaries of what is possible – they dared to dream and now, through our partnership, we can make it a reality.”

CCM’s 3D printed helmet liner

CCM first unveiled its 3D printed NHL-certified hockey helmet liner in September last year, which it created in partnership with 3D printer manufacturer Carbon. Named the Super Tacks X, the helmet was printed using Carbon’s proprietary Digital Light Synthesis (DLS) resin process, and features Next Evolution Sense Technology (NEST).

The lining is comprised of an intricate lattice structure containing more than 130,000 struts which are placed and sized for optimal energy absorption and dissipation, while also ensuring the helmet is breathable, safe, and comfortable.

The helmet lining is now available to all NHL players for the 2021 season, but has already been used by at least three professional players, including the Columbus Blue Jackets’ Seth Jones, who set the record for the most minutes played in a single game while wearing it in the first round of the playoffs.

Automized custom-fitting

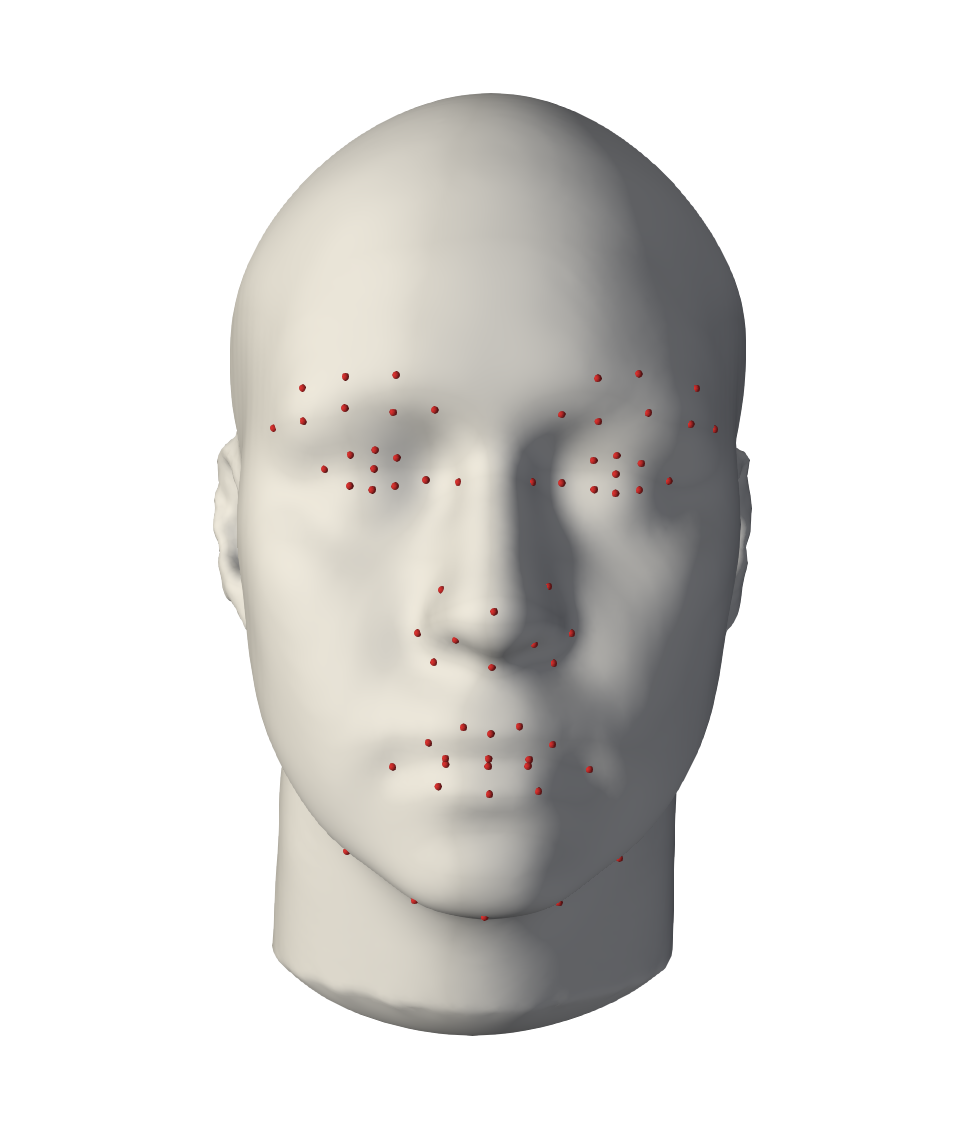

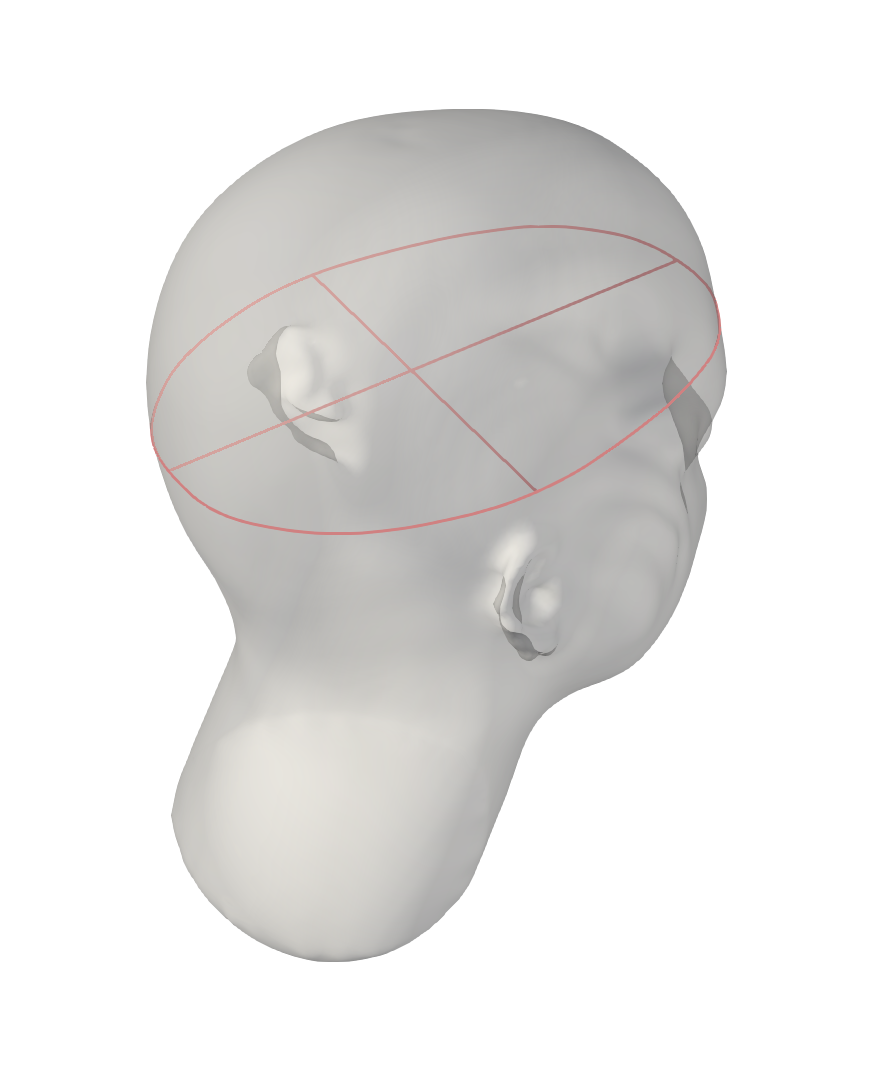

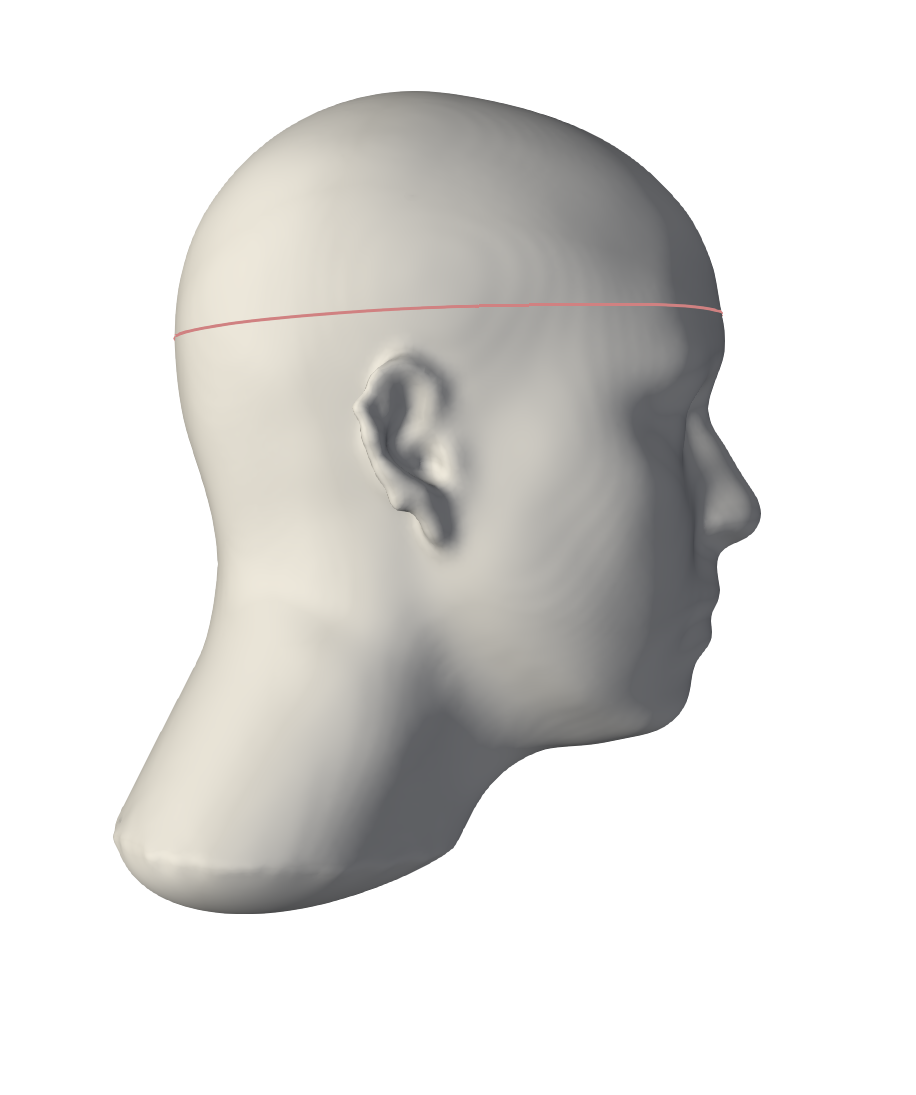

The Super Tacks X will be made available to the public in sizes small, medium, and large, meanwhile elite athletes are able to get them custom-fitted. This is achieved by taking a 3D scan of the player’s head and morphing the padding to conform to the shape of the player’s skull. The helmet liner is then 3D printed to give the final product.

However, this approach required considerable resources due to the intricacy of customizing the lattices and therefore limited its accessibility to the global market beyond professional athletes. The process was also a costly one, and held CCM back from being able to provide the customized liner to a larger pool of consumers.

As such, the company turned to Shapeshift 3D to improve and automate its custom-fitting process so that it could meet the increasing public demand for the 3D printed liner.

“CCM is proud to partner with such an innovative company for the improved processing of the design of our Super Tacks X hockey helmet liner,” said Jeff Dalzell, Chief Product Officer at CCM. “We chose Shapeshift 3D to allow us to bring the custom-fit process used at the elite level to the masses. We were looking for a partner to help with the strong demand and work on an optimized, automated process.

“We truly think that Shapeshift 3D will help us achieve our commercial vision to bring this revolutionary product to as many players as possible globally.”

Shapshift 3D’s fully integrated and scalable software platform is based on patent-pending technology and specializes in the fit-customization of products to the wearer’s body. Powered by artificial intelligence (AI), the platform enables a “perfect” fit while preserving the engineering and design intent of the product.

The company has previously deployed its fit-customization platform for performance and safety applications requiring high compliance standards, such as 3D printed knee braces, custom printed insoles, respiratory masks, and prosthetic limbs.

“This [partnership] is particularly exciting as it showcases the unique value-add of using our software – we allow CCM to customize at scale and low cost while respecting technologies already integrated, such as the NEST tech,” added Borduas.

3D printed sports goods

The benefits of additive manufacturing are being increasingly leveraged within the sports goods industry, with the likes of global sportswear brand adidas utilizing the technology within its sports shoes in order to boost running performance. Fellow footwear giant Nike has also previously cashed in on the action, having created both performance 3D printed elite shoes and exclusive footwear editions for films.

Elsewhere, the cycle sector has shown significant interest in 3D printing, with several companies striving for weight-saving and performance gains in their bike designs using the technology, as well as to create previously unmanufacturable designs.

3D printing has also been used in the design and manufacture of cycle accessories such as helmets, and in the creation of components such as bike pedals and bike saddles.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows CCM has partnered with Shapeshift 3D to leverage its fit-customization platform for its 3D printed hockey helmet liners. Image via Shapeshift 3D.